Production device and method for injection molding type zipper

A technology for producing a device and a zipper, which is applied to household appliances, fastener elements, other household appliances, etc., can solve the problems of incomplete forming deformation and low production efficiency, and achieve the effect of good forming effect, simple structure and preventing influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

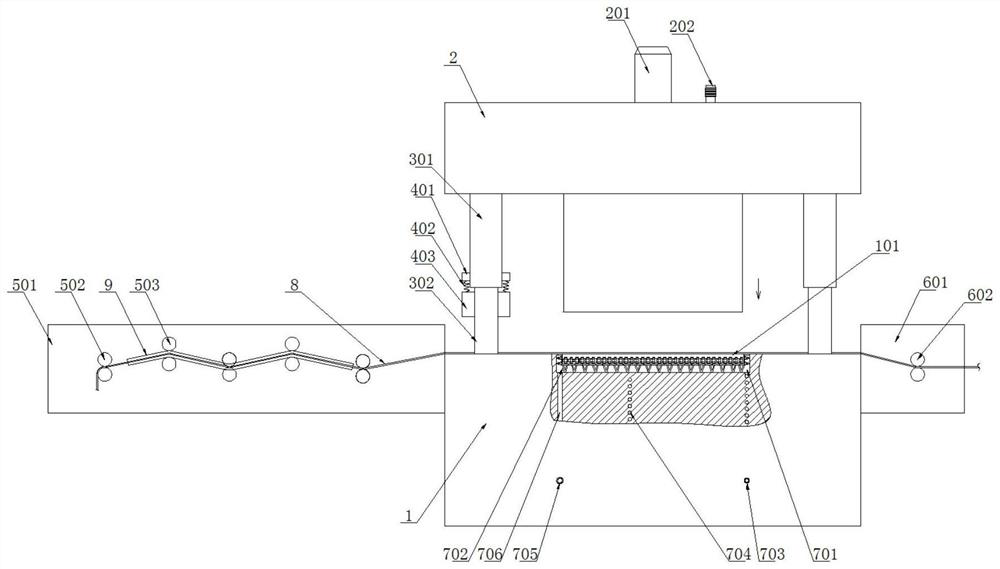

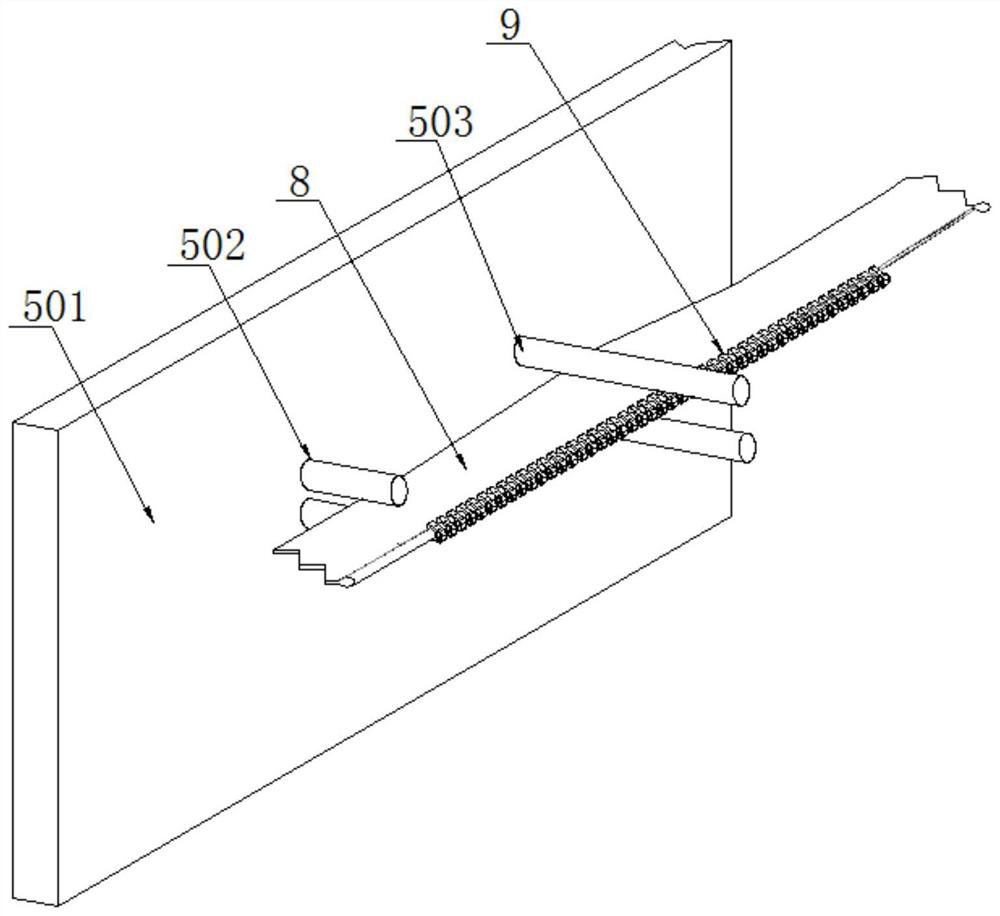

[0031] Such as Figure 1-2 Shown, a kind of production device of injection molded zipper is used for injection molding chain element 9 on chain belt 8 to produce injection molded zipper, comprises lower mold 1, is located at upper mold 2 above lower mold 1, is connected in lower mold 1 and Several buffer mechanisms between the upper mold 2, a chain conveyor mechanism connected to one side wall of the lower mold 1, a chain belt adjustment mechanism connected to the other side wall of the lower mold 1, and a buffer mechanism located close to the chain conveyor mechanism The upper chain belt limiting mechanism and the rapid cooling mechanism arranged in the lower mold 1, the lower mold 1 is provided with an injection molding cavity 101, the chain belt conveying mechanism drives the chain belt 8 to move, and the chain belt adjusting mechanism adjusts the chain belt 8 to The length between the lower mold 1 and the upper mold 2, the chain belt 8 enters the injection molding cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com