Integrated axle hub bearing nut locking device

A technology of locking device and wheel hub bearing, which is applied in the field of axle parts, can solve the problems of affecting the service life of the bearing, occupying a large space, and being prone to early failure, so as to improve the service life, increase the assembly efficiency and reduce the stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

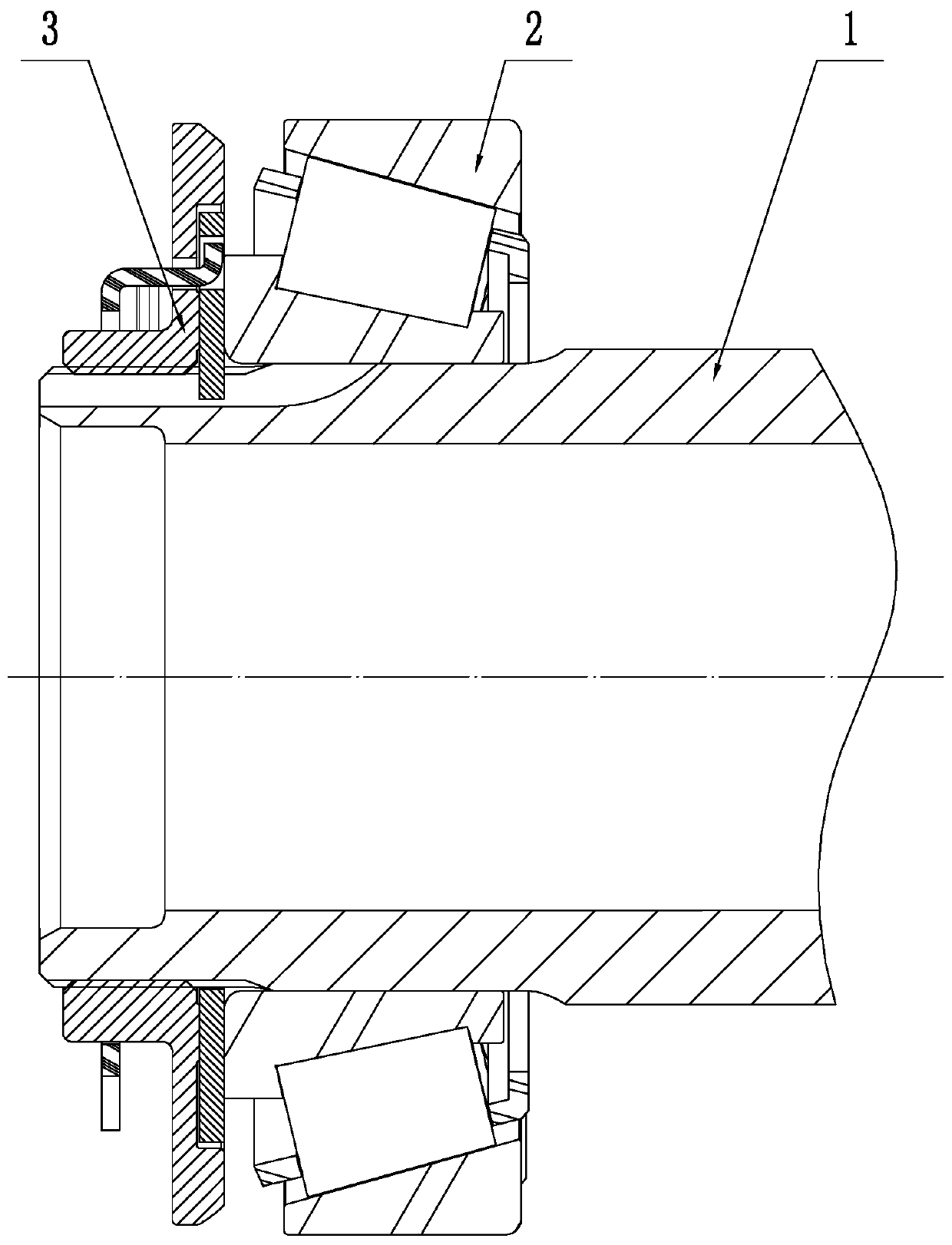

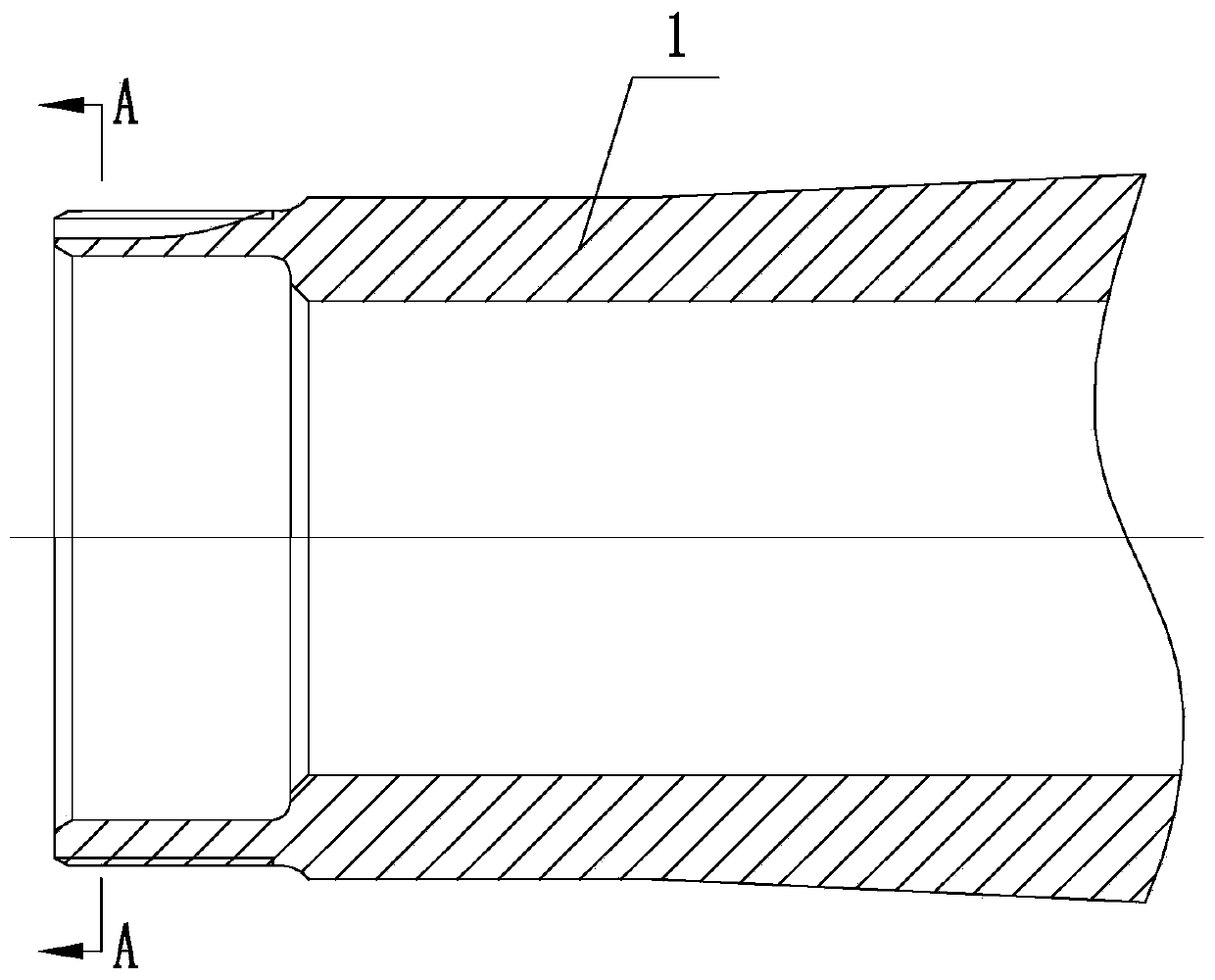

[0041] An integrated axle hub bearing nut locking device, comprising an axle housing shaft tube 1, a hub bearing 2, and an integrated locking nut assembly 3, wherein:

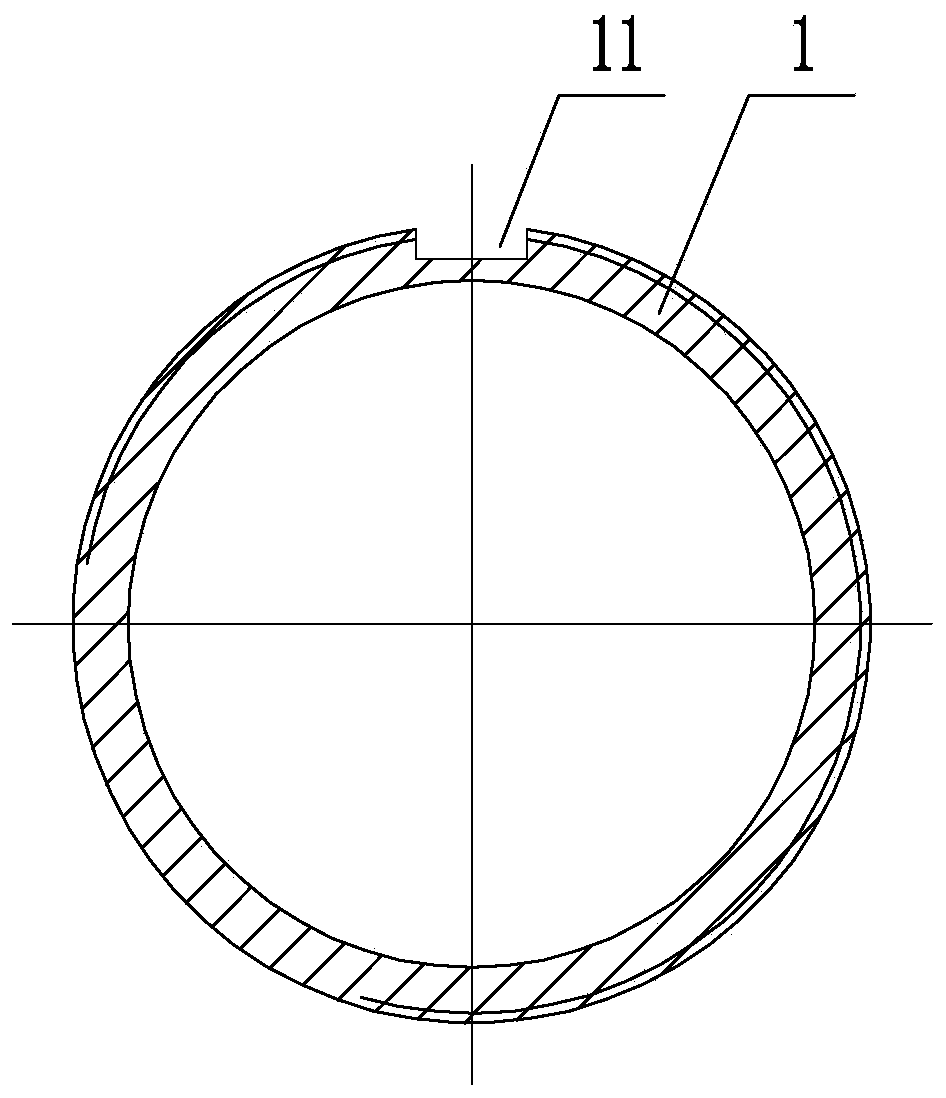

[0042] The outer circle of the end of the axle housing shaft tube 1 is provided with external threads, and the outer circle of the end of the axle housing shaft tube 1 is also provided with a card slot 11;

[0043] Described hub bearing 2 is known prior art.

[0044] The integrated lock nut assembly 3 includes an elastic washer 31, an adjusting nut 32, and a limit ring 33. One end of the elastic washer 31 fits with the end face of the hub bearing 2, and the other end of the elastic washer 31 fits with the adjusting nut. 32, the elastic washer 31 is evenly distributed with 20 to 40 limit holes 311, and the inner hole wall of the elastic washer 31 is also provided with an anti-rotation tab 312, and the anti-rotation tab 312 is connected with the axle housing The locking groove 11 on the outer circle of the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com