Front windshield structure capable of being quickly disassembled and assembled

A front windshield, windshield technology, applied in the direction of window device, sealing device, transportation and packaging, etc., can solve the problems of poor repair and maintainability, and achieve the effect of improving repairability and maintainability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments

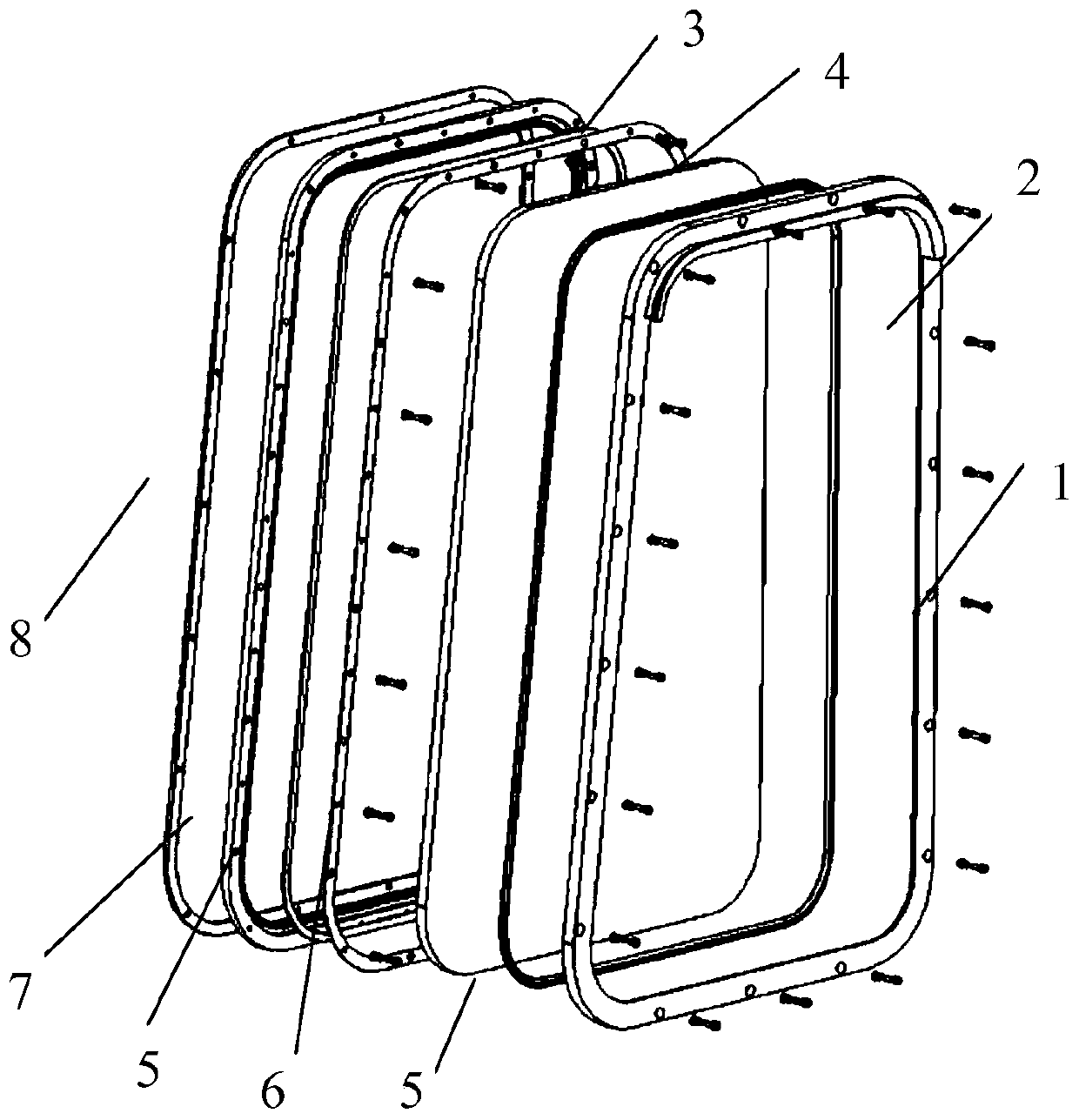

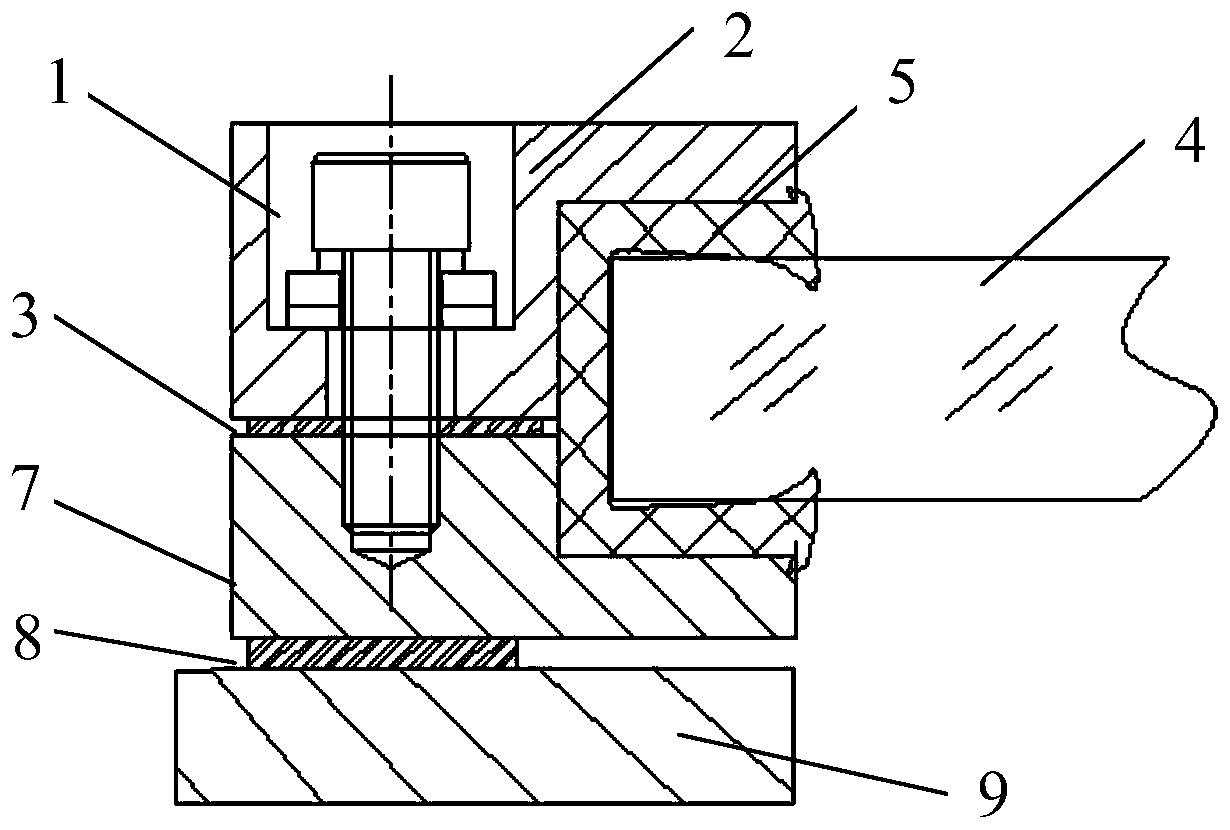

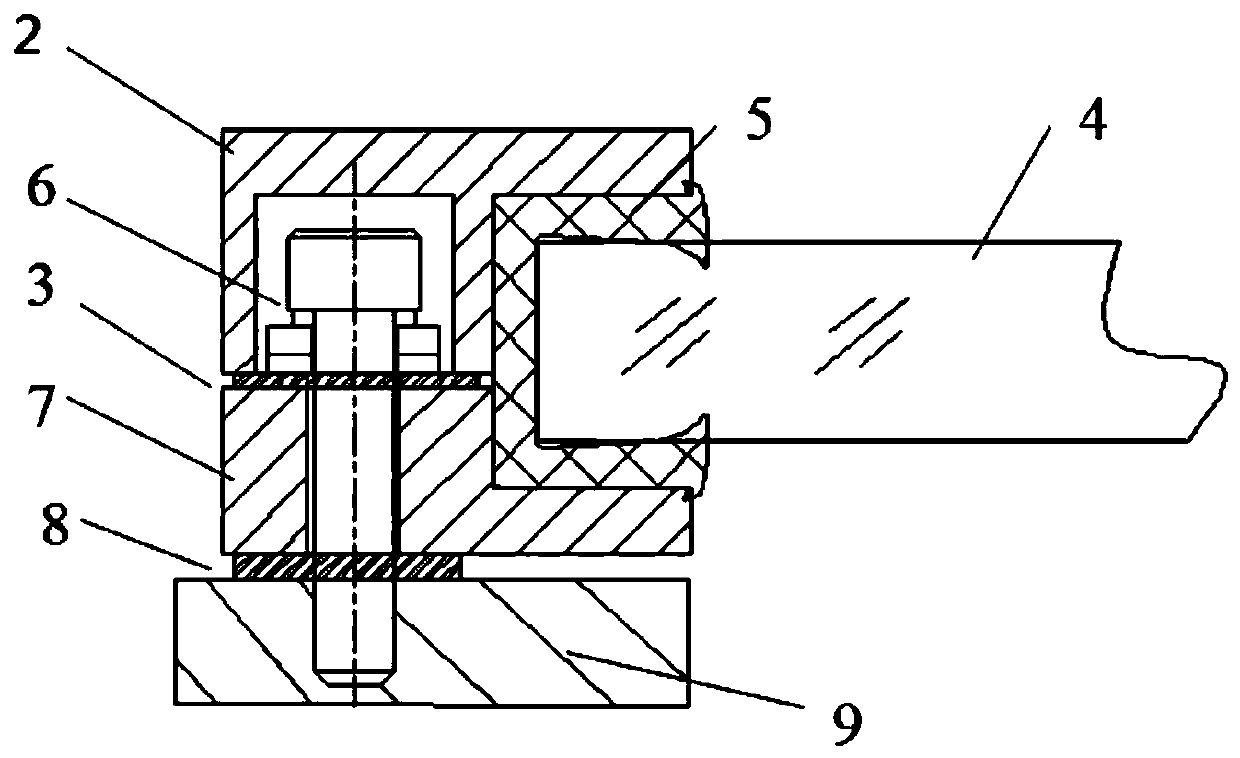

[0017] Such as Figure 1-3 As shown, the windshield 4 is sandwiched between the outer window frame 2 and the inner window frame 7 through the glass glue strip 5, and is fastened by the outer frame mounting screws 1, and the inner window frame and the outer frame are sealed by the outer frame sealing strip 3 window frame. The inner window frame 7 is installed on the front head cover 9 by the inner frame mounting screws 6 and sealed by the inner frame sealing rubber strip 8, and the inner frame mounting screws and the outer frame mounting screws are installed in a misplaced manner.

[0018] When installing the front windshield 4, first install the inner window frame 7 on the front head cover 9 with the inner frame mounting screws 6 and seal it with the serial number inner frame sealing strip 8, and then the outer window frame 2 and the windshield 4 , Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com