Automatic simple portal crane and application method thereof

A simple, gantry technology, applied in the direction of cranes, traveling mechanisms, trolley cranes, etc., can solve the problems of high manpower and material resources for lifting and transporting gantry cranes, inability to achieve up and down lifting or folding, and inability to pass through, so as to facilitate transportation. Goods, saving manpower and material resources, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

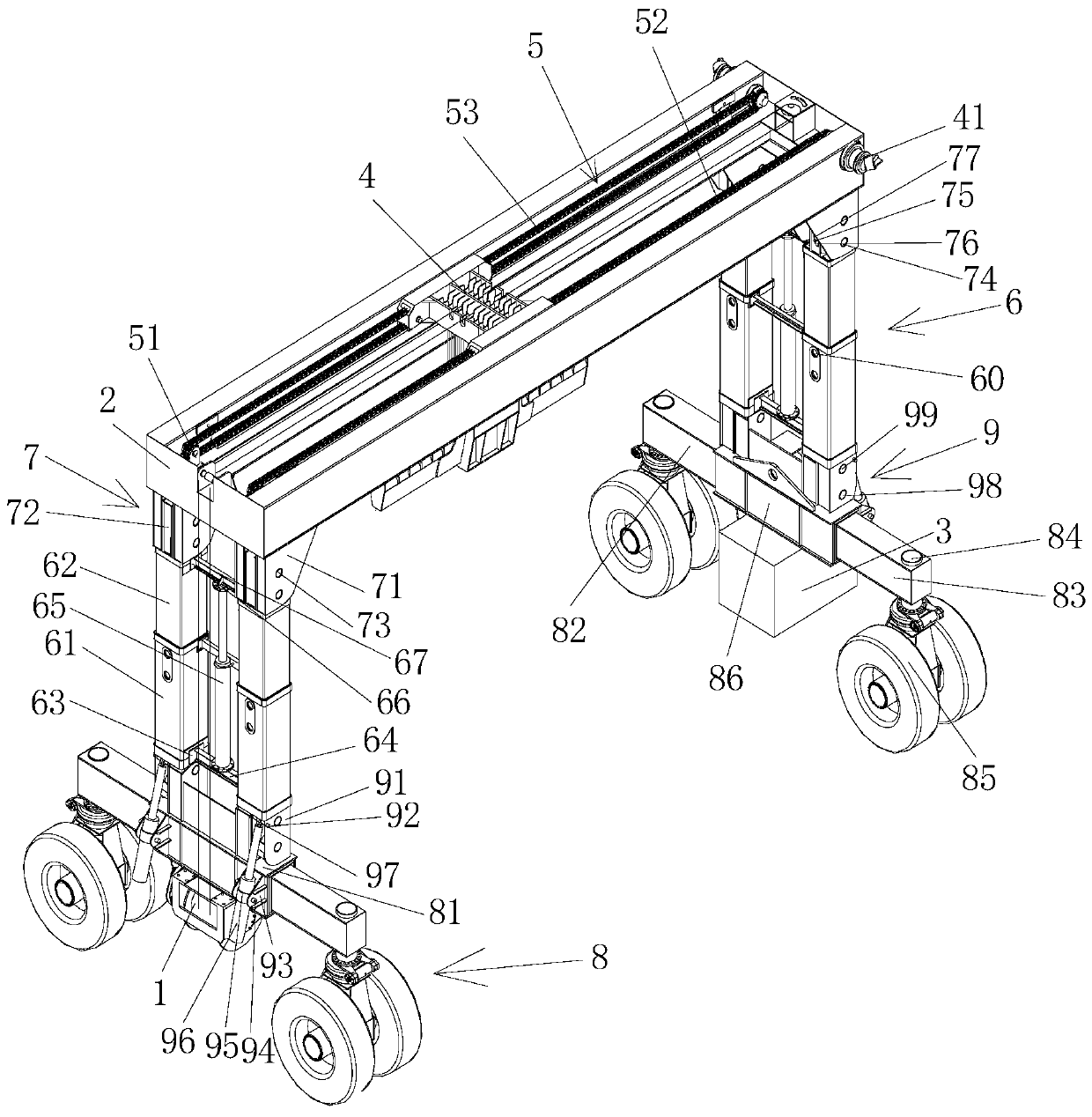

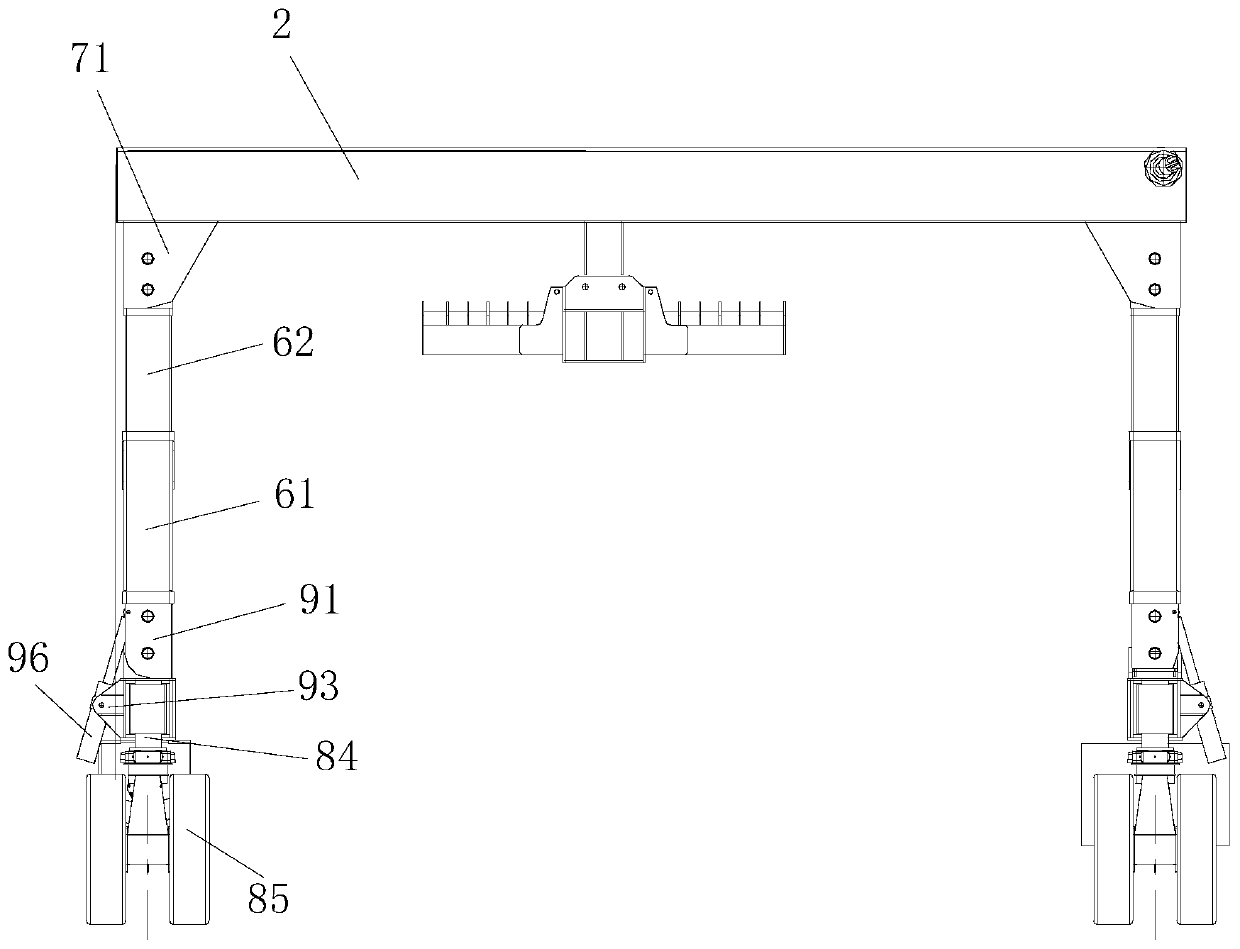

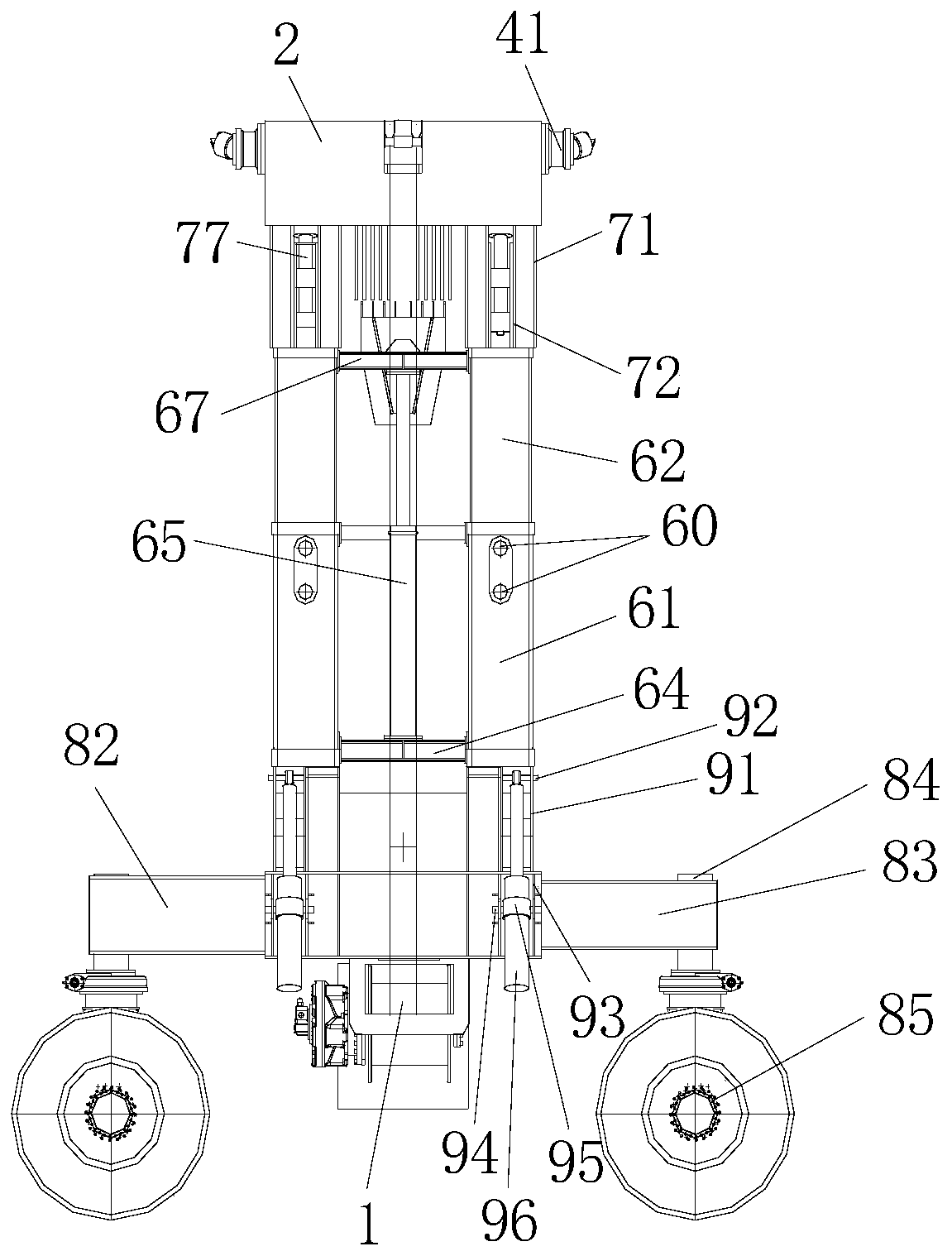

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] see Figure 1 to Figure 5 As shown, the present invention provides an embodiment: an automatic simple door machine, including a hydraulic winch 1, a girder assembly 2, a hydraulic tank 3, a crown block 4, and a crown block traverse motor 41, and the girder assembly 2 front and rear The right end of the surface is provided with the crane traversing motor 41, the crane 4 is erected between the front and rear crossbars in the girder assembly 2, and the crossbar is arranged between the front and rear crossbars of the girder assembly 2. The crane traversing motor 41 drives the moving mechanism 5 for the crane to move left and right; the left and right ends of the lower surface of the girder assembly 2 are provided with a telescopic mechanism 6 for supporting the girder assembly 2, and the telescopic mechanism 6 A first folding mechanism 7 for folding the equipment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com