A permanent magnet eddy current braking device for a fixed air gap elevator

A technology of permanent magnet eddy current and braking device, applied in the direction of hoisting device, etc., can solve the problems of non-adjustable braking force, low braking force control precision, and inability to synergize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

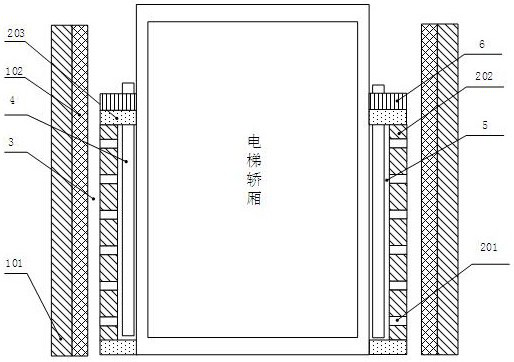

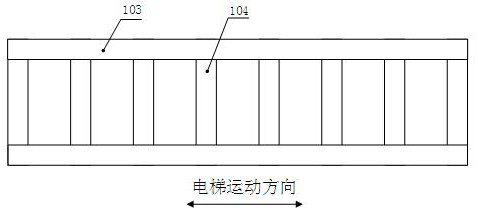

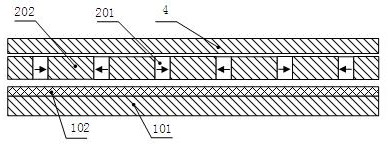

[0023] Such as figure 1 As shown, the present invention discloses a permanent magnet eddy current braking device for a fixed air gap type elevator, which includes a conductor stator fixed on the wall of the elevator shaft and a built-in permanent magnet mover fixed on the outside of the elevator car; the conductor stator There is an air gap 3 between the built-in permanent magnet mover; a magnetism regulating plate 4 is set between the built-in permanent magnet mover and the elevator car, and there is an air gap 3 between the built-in permanent magnet mover and the magnetism regulating plate 4 A small air gap 5; the coupling area between the built-in permanent magnet mover and the magnetic modulation plate 4 is adjusted by an electronically controlled mechanical operating mechanism 6 .

[0024] Such as figure 1 As shown, the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com