Addition-type silicone potting adhesive room temperature adhesive active substance and its preparation method and application

A technology of silicone potting glue and addition molding, which is applied in the direction of adhesives, etc., can solve the problems of poor adhesion, low waterproof level, affecting the performance of electronic products and rapid development, etc., and achieves reliable adhesion and simple and easy preparation methods The effect of easy and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

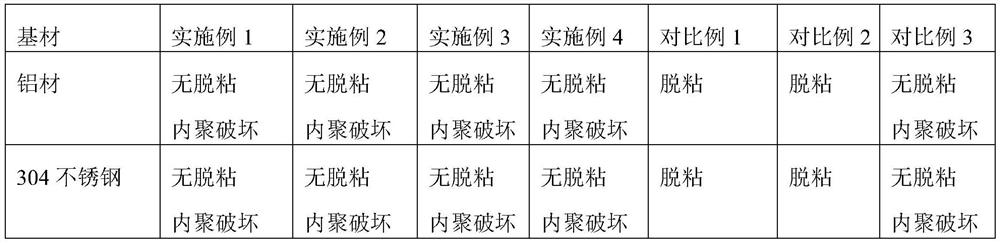

Embodiment 1

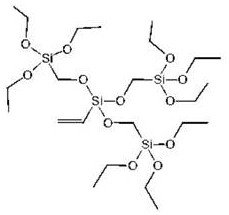

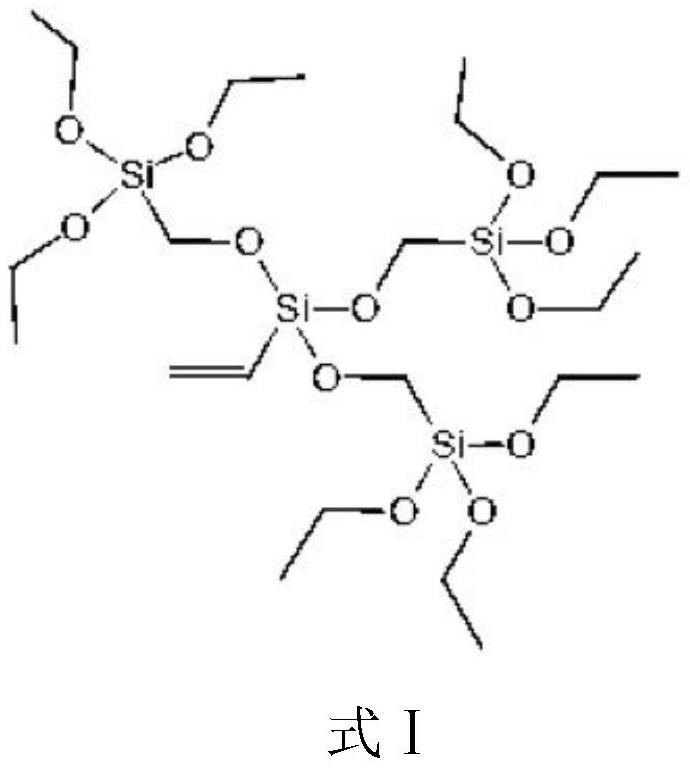

[0040] 1. Put 100 parts by mass of vinyltrimethoxysilane and 150 parts by mass of absolute ethanol into the reactor, lower the temperature of the material to 10°C; put in 400 parts by mass of hydroxymethyltriethoxysilane, and stir for 15 minutes; Then add 0.25 parts by mass of isopropyl titanate, after the dropwise addition, continue to stir and react for 4 hours; the temperature of the material is raised to 60°C, and the de-lowering reaction is carried out for 1 hour (vacuum degree is 0.09MPa); the addition-type silicone potting adhesive is bonded at room temperature Actives.

[0041] 2. Take 200 parts by mass of the addition-type silicone potting adhesive obtained in step 1 and cool it to 20°C, add 1000 parts by mass of toluene and 1 part by mass of isopropyl titanate under nitrogen protection, and stir for 15 minutes. The addition type silicone potting glue room temperature bonding composition is obtained.

[0042] 3. Apply the silicone potting adhesive room temperature bo...

Embodiment 2

[0044] 1. Put 100 parts by mass of vinyltrimethoxysilane and 150 parts by mass of absolute ethanol into the reactor, lower the temperature of the material to 10°C; put in 400 parts by mass of hydroxymethyltriethoxysilane, and stir for 15 minutes; Then add 0.25 parts by mass of isopropyl titanate, after the dropwise addition, continue to stir and react for 4 hours; the temperature of the material is raised to 60°C, and the de-lowering reaction is carried out for 1 hour (vacuum degree is 0.095MPa); the addition-type silicone potting adhesive is bonded at room temperature Actives.

[0045] 2. Take 400 parts by mass of the addition-type silicone encapsulant obtained in step 1 and cool the adhesive active substance at room temperature to 20°C. Add 3000 parts by mass of hexamethyldisiloxane and 10 parts by mass of tetrabutyl zirconate under nitrogen protection. part, and stirred for 15 minutes to obtain an addition-type silicone potting adhesive room temperature bonding composition....

Embodiment 3

[0048] 1. Put 100 parts by mass of vinyltrimethoxysilane and 150 parts by mass of absolute ethanol into the reactor, lower the temperature of the material to 10°C; put in 400 parts by mass of hydroxymethyltriethoxysilane, and stir for 15 minutes; Then add 0.25 parts by mass of isopropyl titanate, after the dropwise addition, continue to stir and react for 4 hours; the temperature of the material is raised to 60°C, and the de-lowering reaction (vacuum degree is 0.098MPa) is 1 hour; the addition type silicone potting adhesive is bonded at room temperature Actives.

[0049] 2. Take 300 parts by mass of the addition-type silicone encapsulant obtained in step 1 and cool the adhesive active substance at room temperature to 20°C, add 2000 parts by mass of xylene under the protection of nitrogen, 5 parts by mass of zirconate were stirred for 15 minutes to obtain an addition type silicone potting glue room temperature bonding composition.

[0050] 3. Apply the silicone potting adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com