Plate bar positioning and dotting device

A reinforcement and positioning disc technology, which is applied in the direction of construction, building structure, and building materials processing, can solve the problems of tediousness, large workload of reinforcement standards, time-consuming and labor-intensive problems, etc., and achieve simple dotting method, simple structure, and easy to use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of the present invention, the following description is made with reference to the accompanying drawings and embodiments.

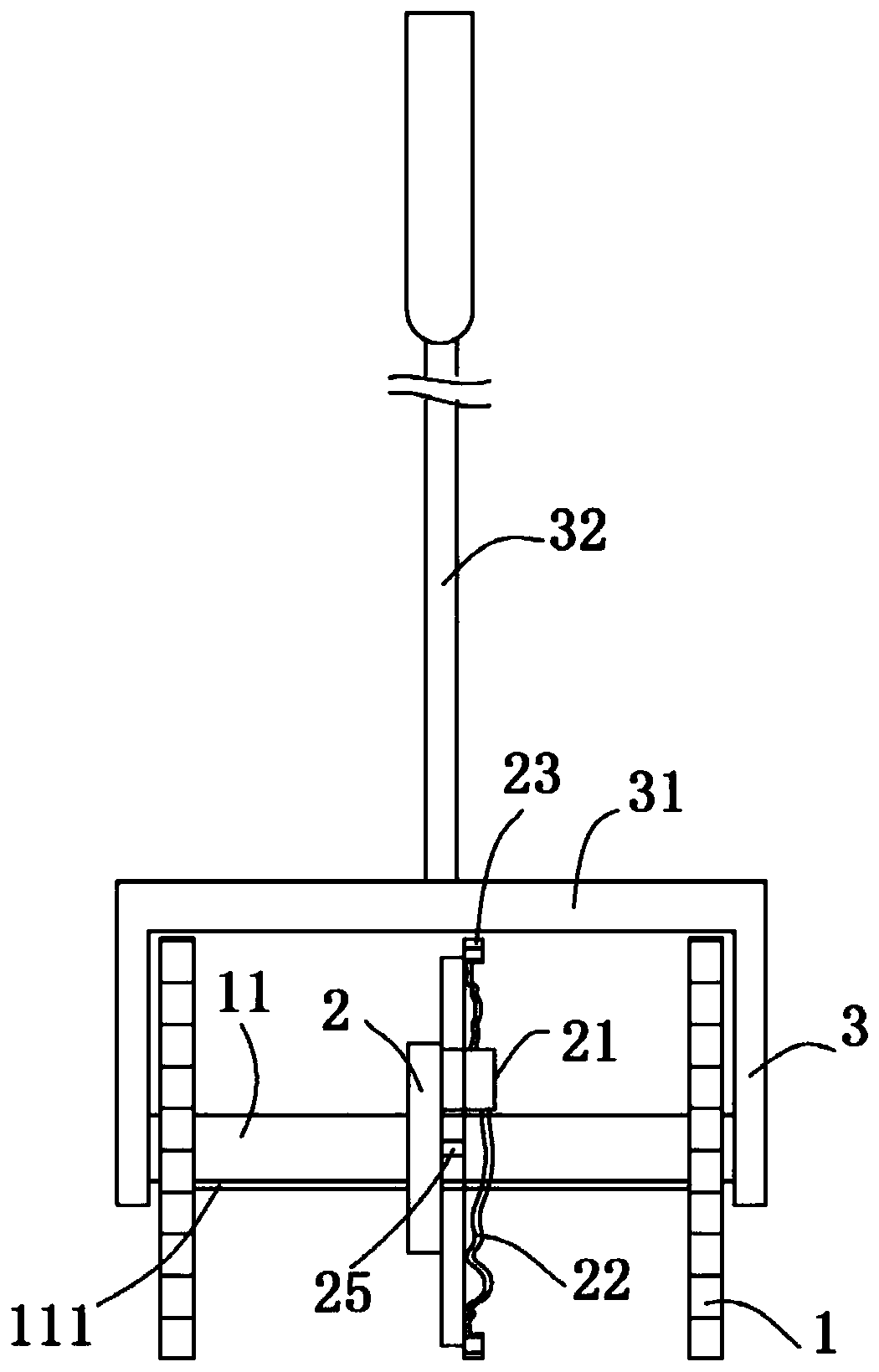

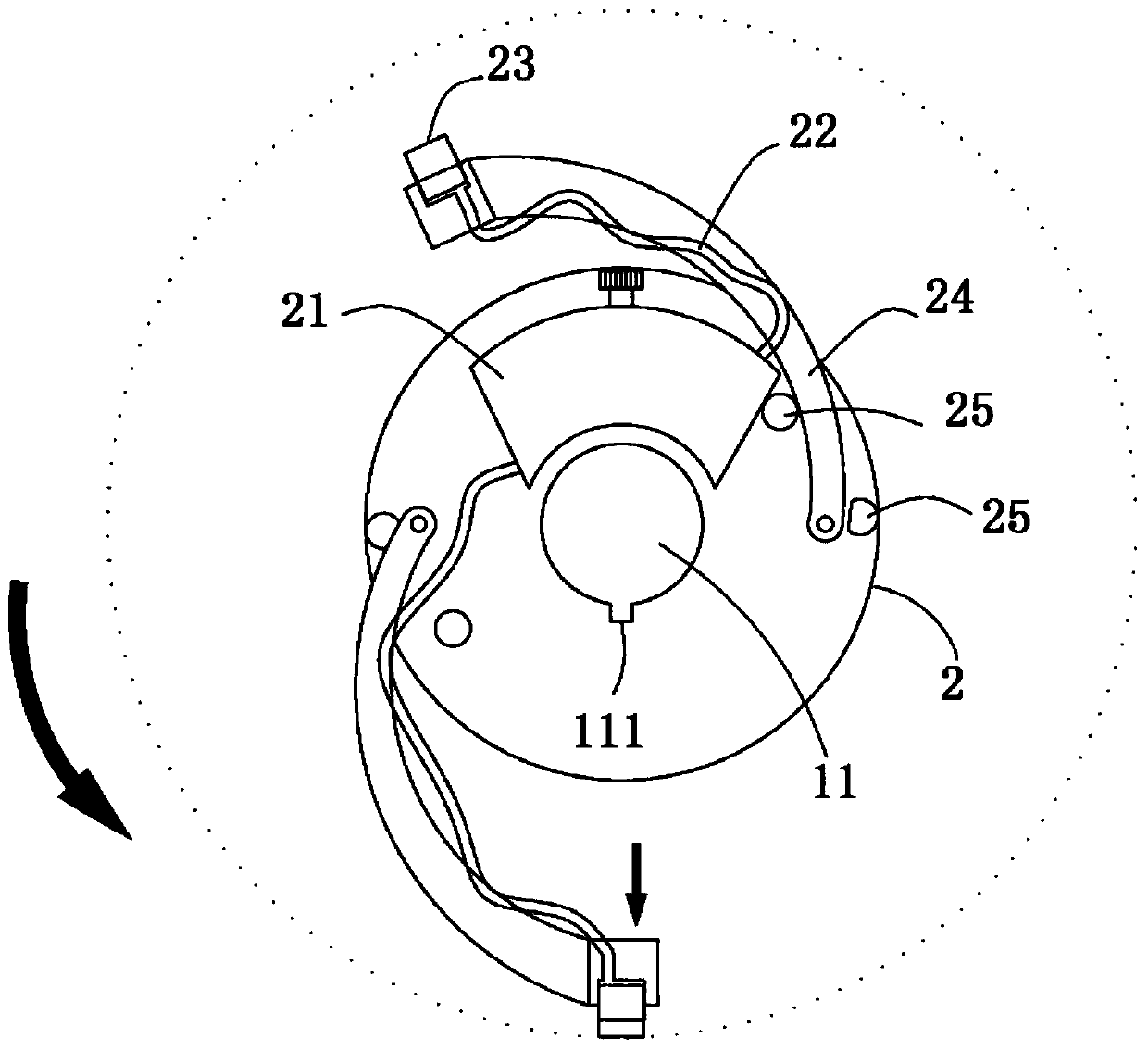

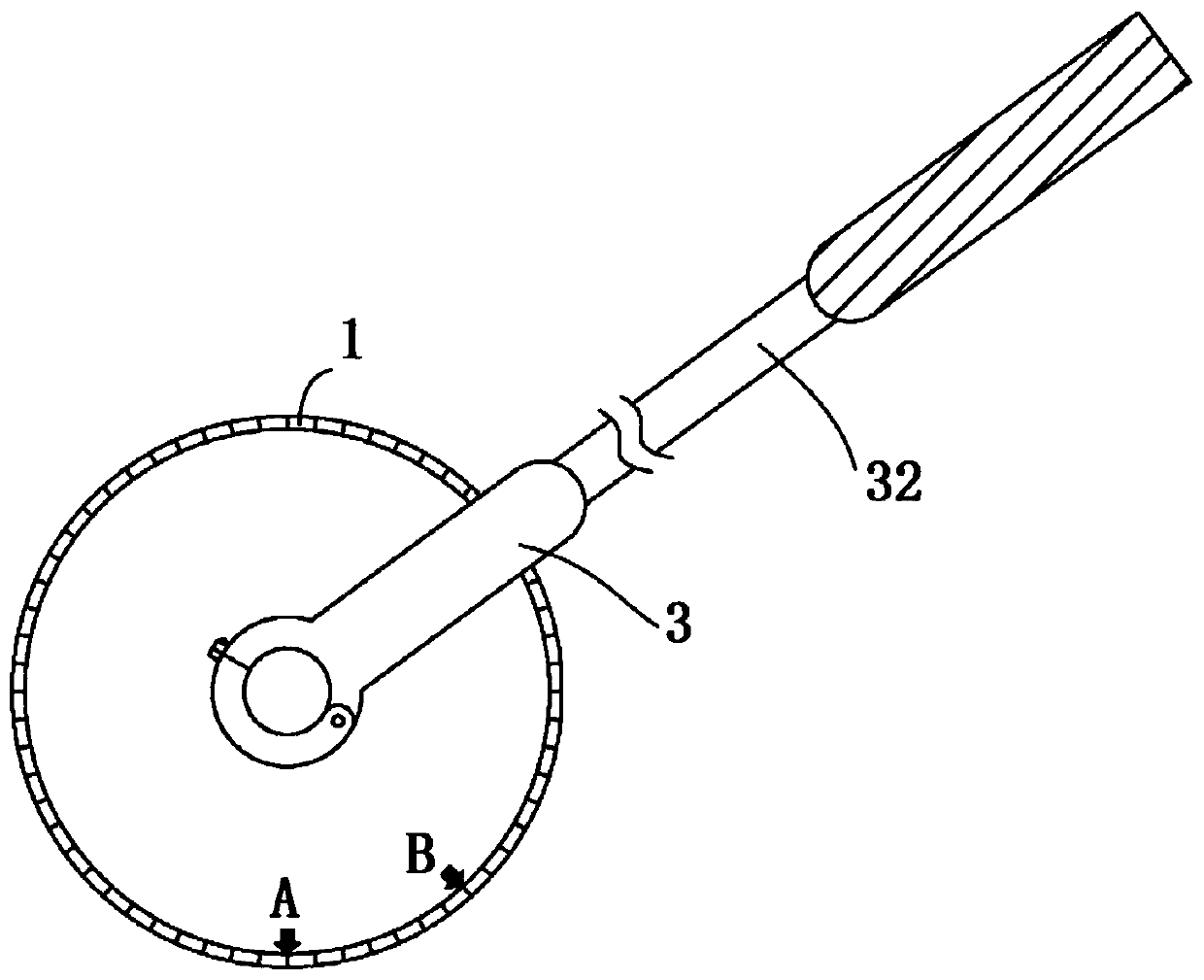

[0030] see figure 1 , figure 2 As shown, the present invention provides a rib positioning and dotting device, comprising: two rollers 1 arranged in parallel, the middle parts of the two rollers 1 are connected by a synchronous shaft 11; a positioning disc 2 is coaxially fixed on the On the synchronous shaft 11; the ink bag 21 is fixed on the positioning plate 2, the ink bag 2 is provided with an ink delivery tube 22, and the first end of the ink delivery tube 22 communicates with the ink bag 22, so that The second end of the ink delivery tube 22 is connected with a dotting part 23; a swing arm 24, the first end of which is hinged on the positioning plate 2, and the second end of the swing arm 24 is fixed with the The dotting part 23 connected to the ink delivery tube 22, the outer edge of the dotting part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com