Full-automatic cleaning electrostatic type oil fume purifying all-in-one machine

A fully automatic cleaning and oil fume purification technology, which is applied in the fields of oil fume removal, heating methods, household heating, etc., and can solve problems such as difficult cleaning, dirty interior, and difficult disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below according to the accompanying drawings and some embodiments.

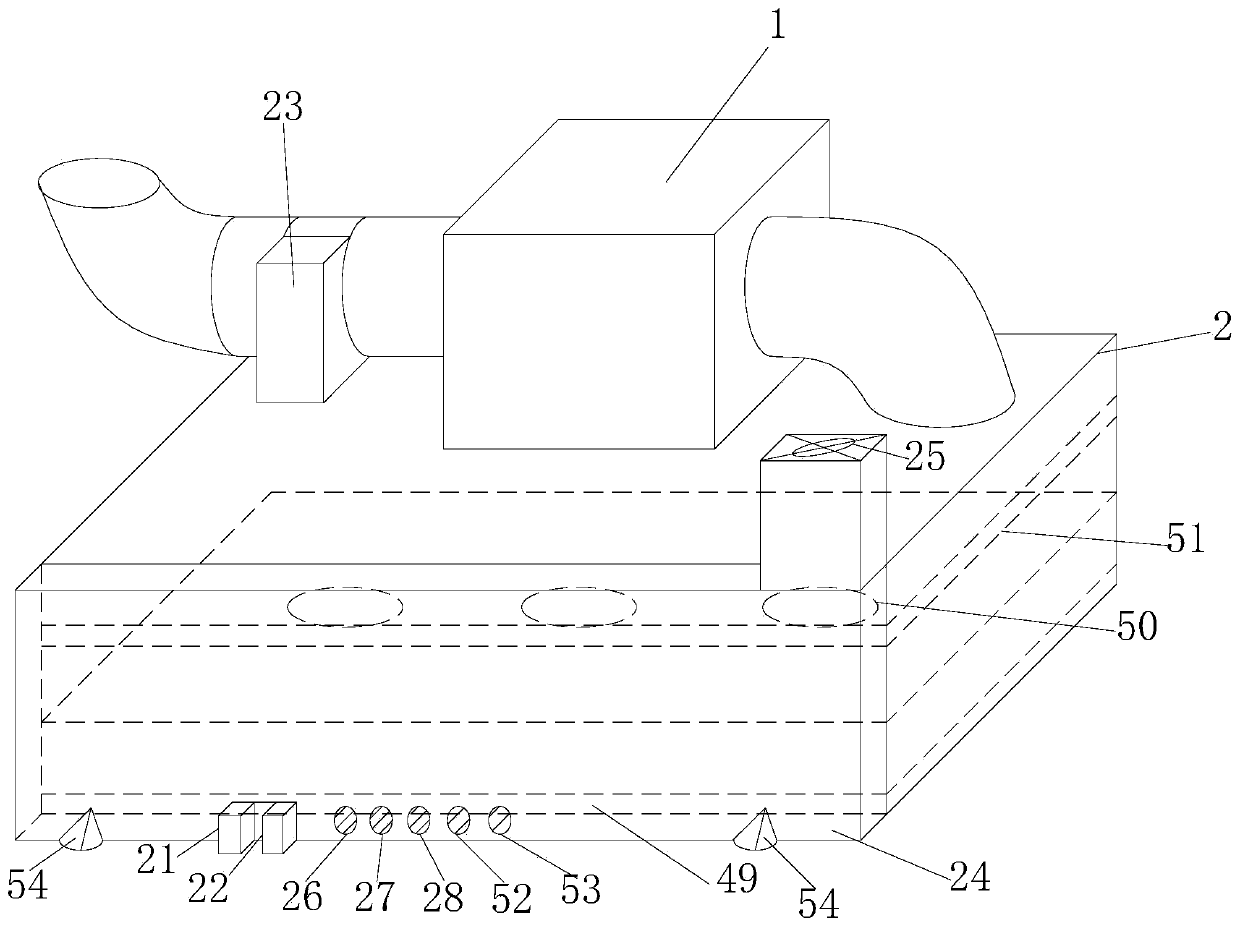

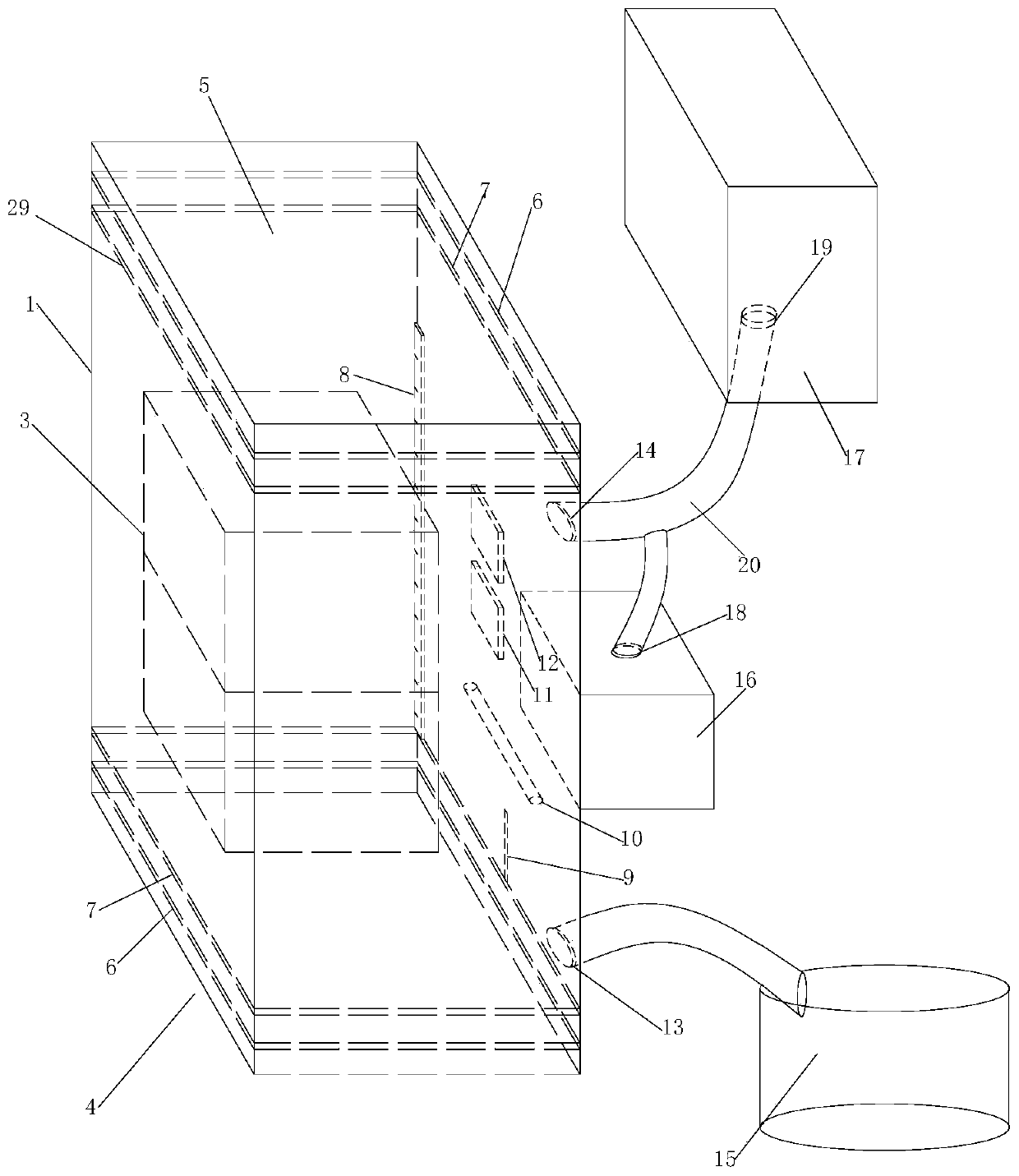

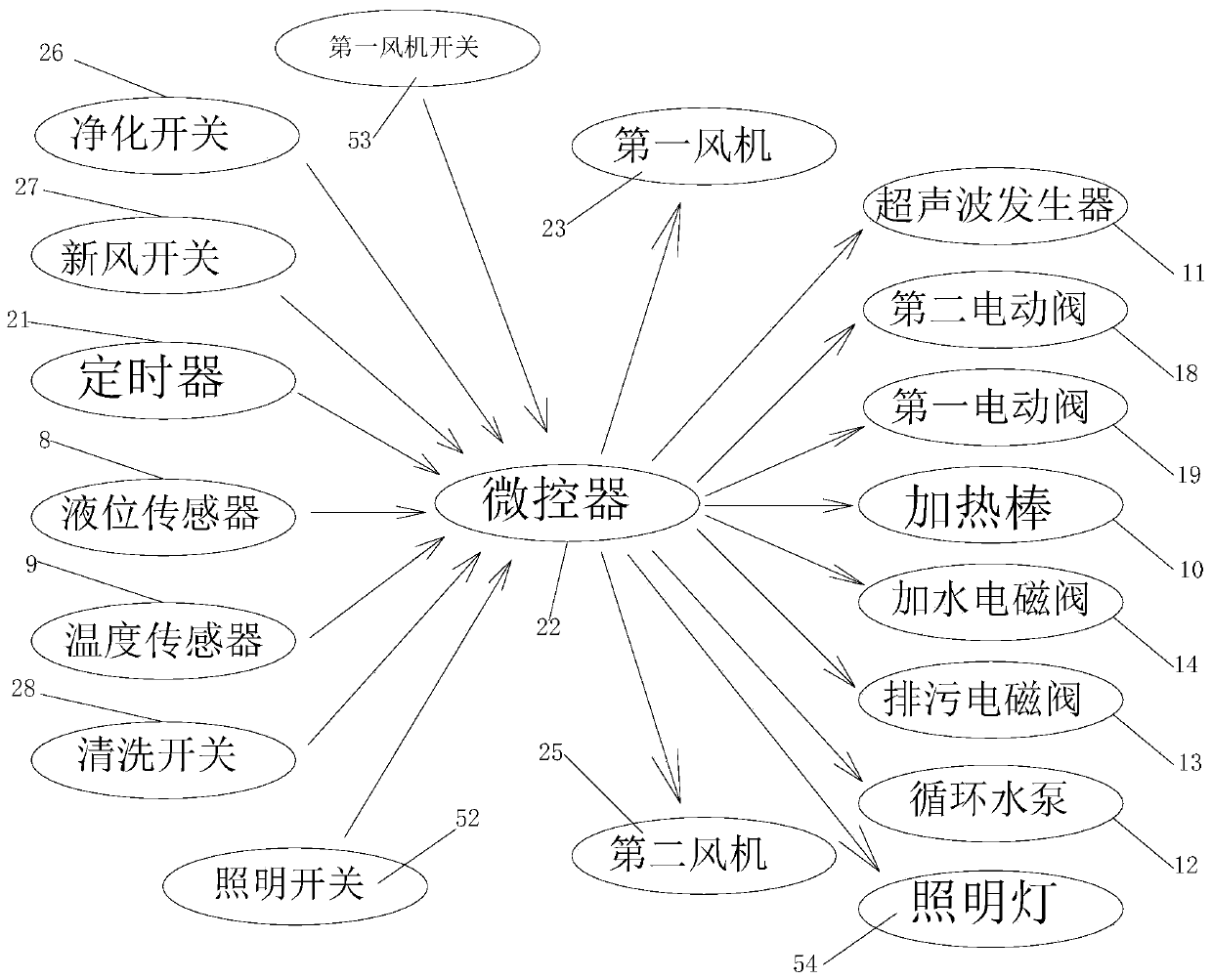

[0032] Figure 1-9 Among them, a fully automatic cleaning electrostatic fume purification integrated machine, including a fume hood housing 2, a fume purification device, and a cleaning device capable of cleaning the fume purification device, the fume purification device is connected to the top outer surface of the fume hood housing 2, The cleaning device is located in the oil fume purification device; the oil fume purification device includes a purification assembly that can purify large oil particles, an interception assembly that can intercept large oil particles, and a first fan 23, and the interception assembly is arranged in the smoke hood shell 2, Fixed with the inner wall of the smoke hood shell 2; the purification assembly includes a purification box 1, a plurality of first air equalizing plates 7, and a plurality of electrostatic fields 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com