Turbine working blade tenon tooth profile detection method and special positioning device

A positioning device and contour detection technology, which is applied in the field of aero-engines, can solve the problems that manual measurement repeatability cannot be compared with image detection equipment, data cannot be saved, and measurement efficiency is low, so as to achieve the effect of improving detection efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

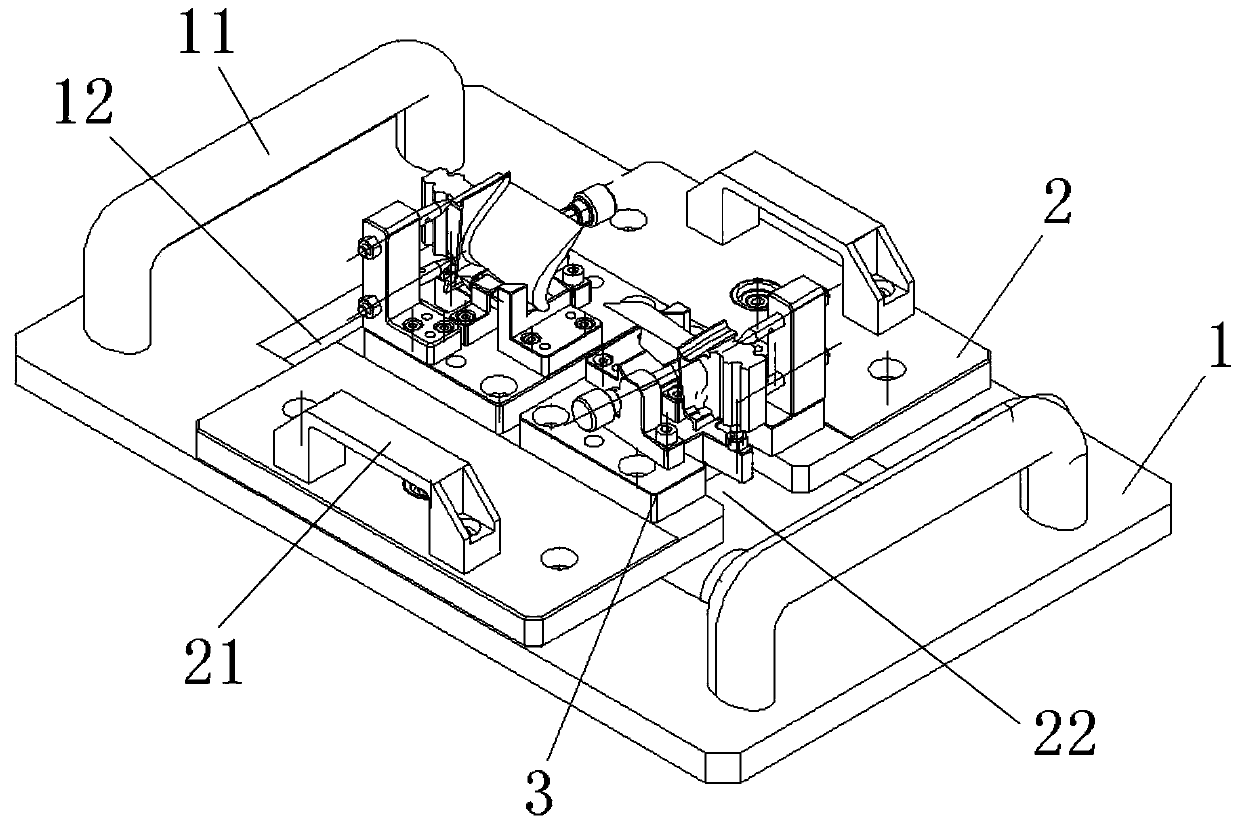

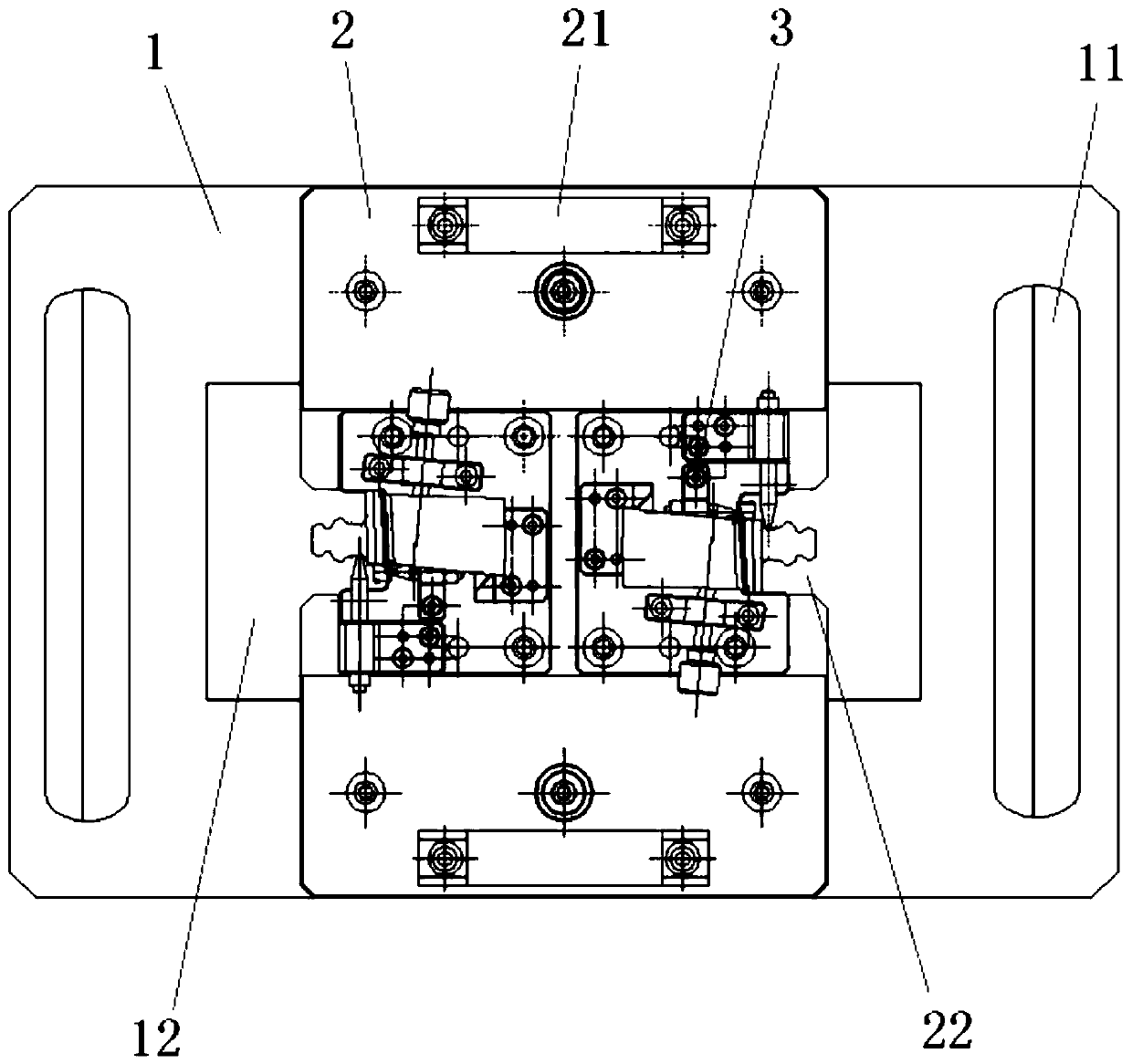

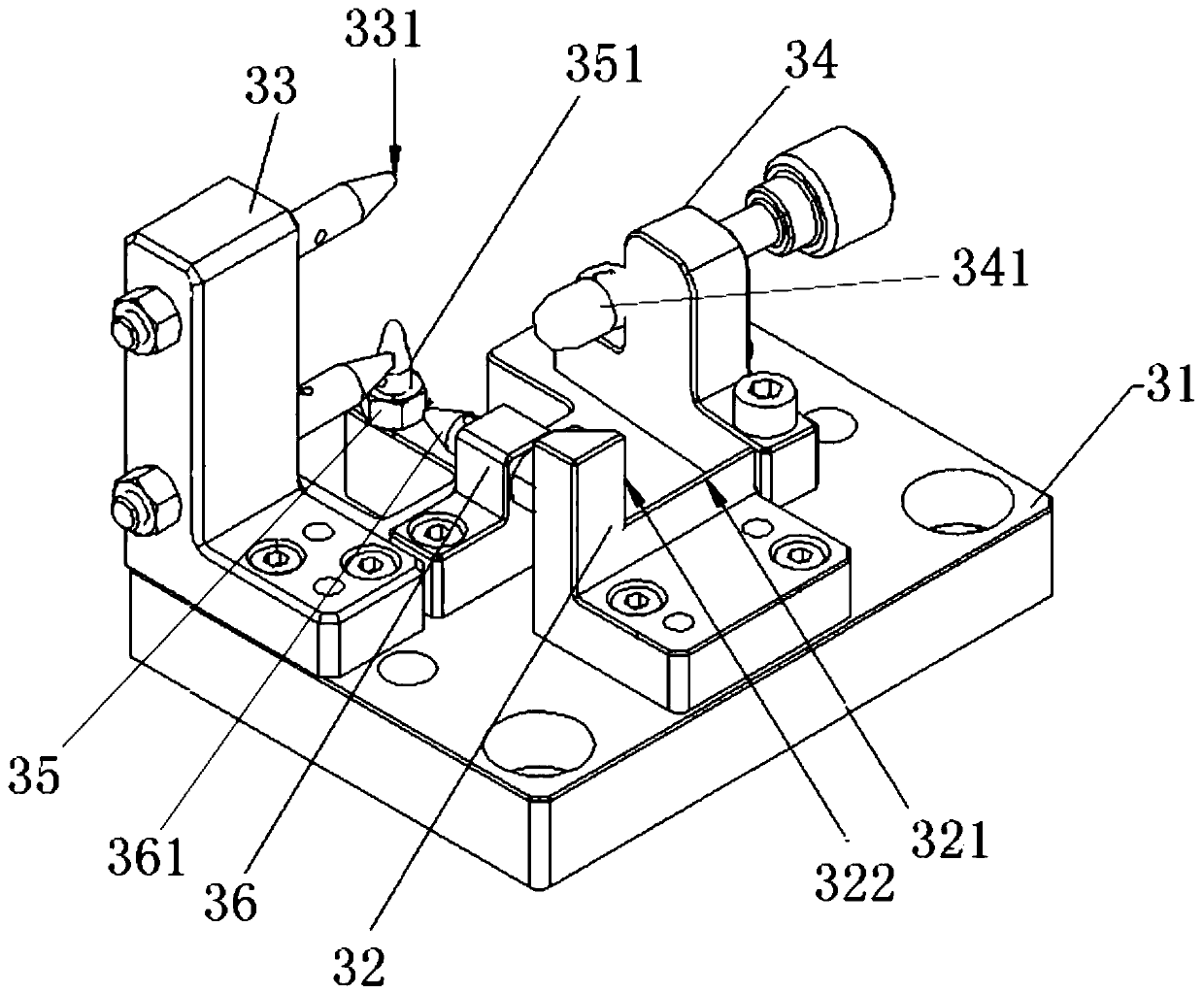

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited thereto.

[0023] A method for detecting the mortise tooth profile of a turbine working blade, which uses a transmission device to load and unload materials on a detection workbench, and detects through a detection device and a computer. It is characterized in that it includes the following steps:

[0024] a. Compile a special testing program according to the computer class in the profile requirements of the tenon teeth of the blade; and design and manufacture a special positioning device for clamping the blade for testing. The design and manufacturing steps of the special positioning device are:

[0025] Analyze the size and basic shape, positioning requirements, and detection requirements of the tenon tooth profile of the turbine working blade, and propose a device desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com