Edging blind riser for casting

A technology of concealed riser and welt, which is used in casting molding equipment, molds, cores, etc., can solve the problems of reducing the qualified rate of castings, unable to solve shrinkage porosity, and reducing the quality of castings, so as to improve the quality and structure of casting products. Simple, effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

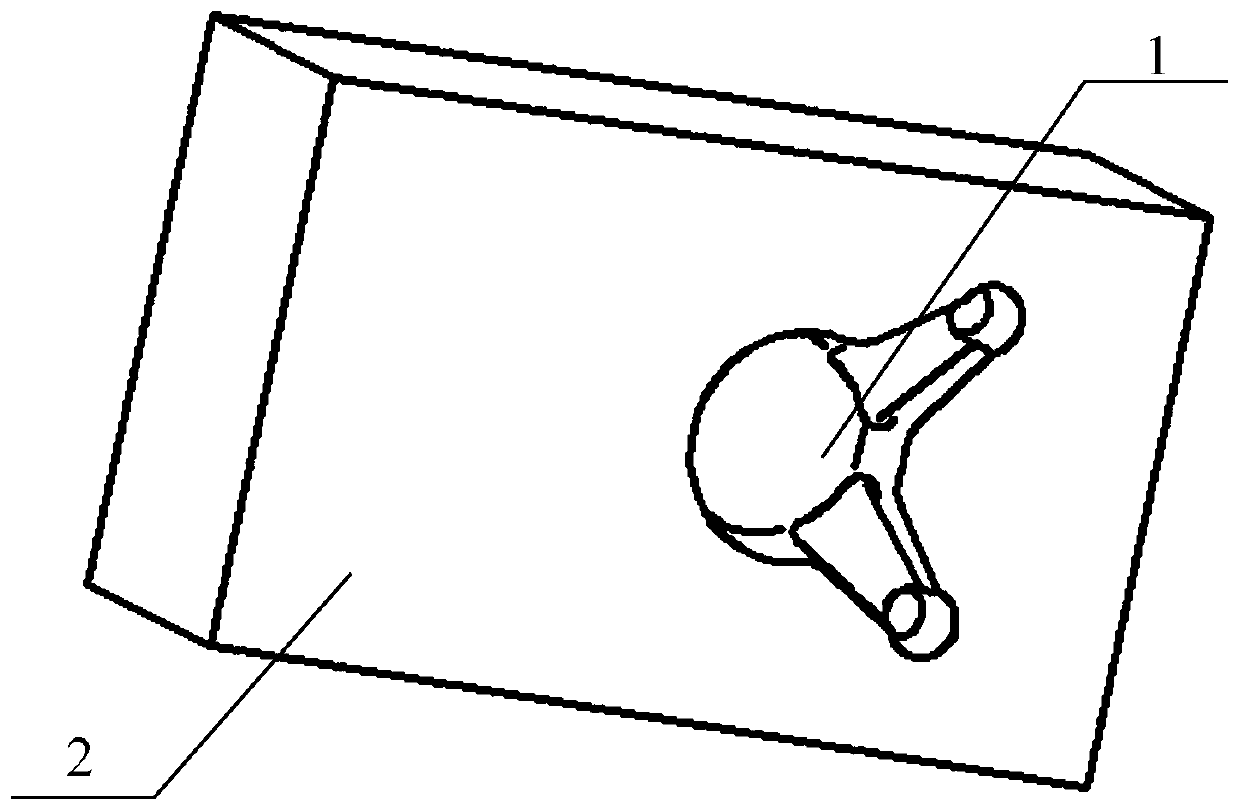

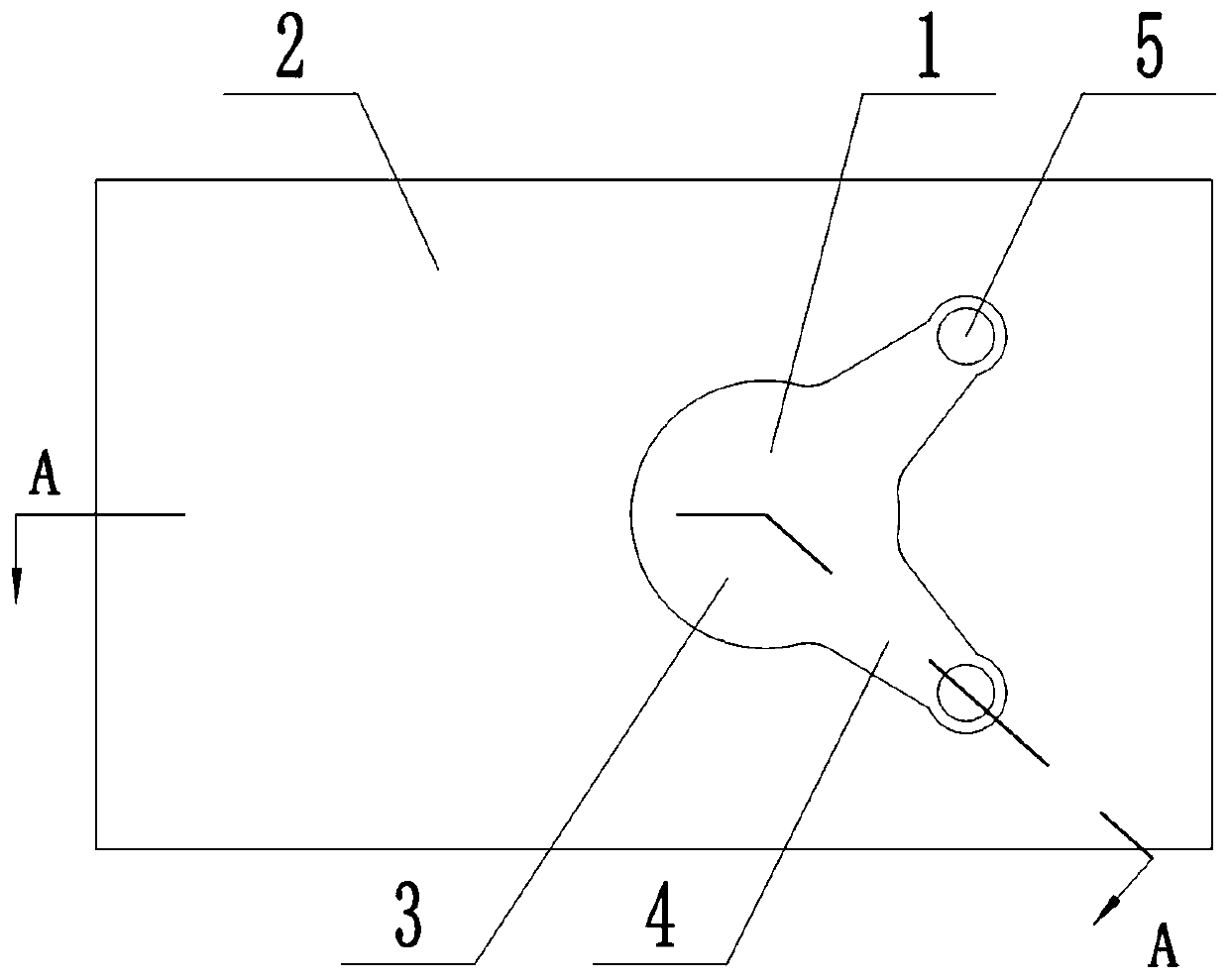

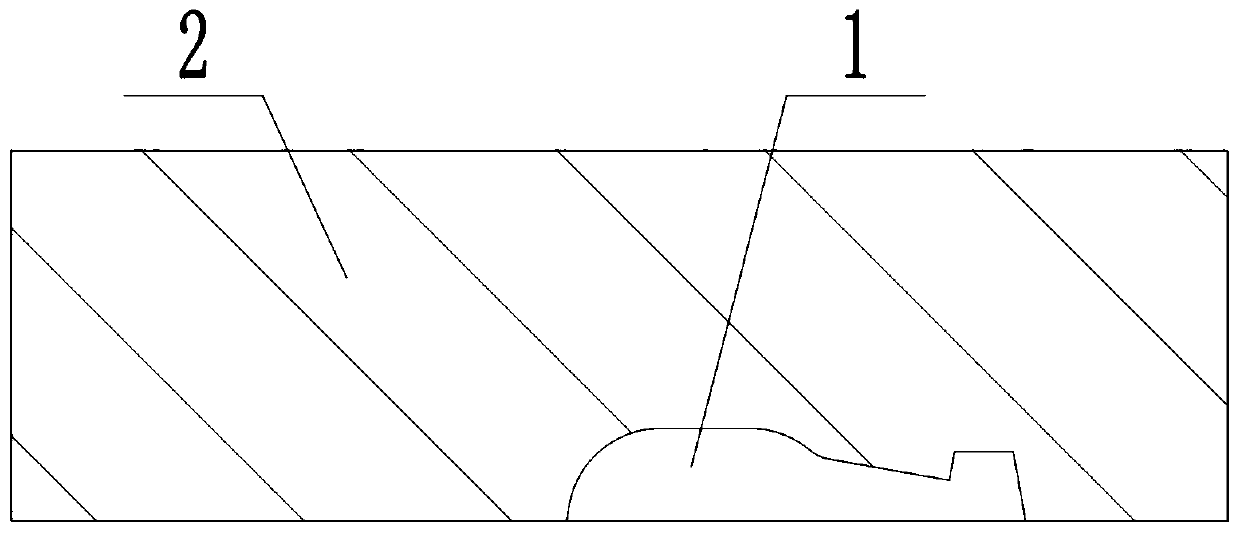

[0019] Such as Figure 1 to Figure 7 As shown, a welted riser for pouring includes a riser body 1, which is characterized in that the riser body 1 is arranged on the lower mold 2, and the riser body 1 includes an arc-shaped groove 3, two Feeding channel 4 and two feeding holes 5, the two feeding holes 5 are connected to the arc-shaped groove 3 through the feeding channel 4, the side 1 of the riser body of the lower mold 2 is attached to the product 6 port Closed, and the feeding hole 5 is aligned with the control boss of the product 6 port, and the arc-shaped groove 3 of the dark riser body 1 is provided with a sand core riser 7.

[0020] The sand core riser 7 is located in the inner cavity of the product 6 and is attached to the side wall of the inner cavity of the product 6 .

[0021] The sand core riser 7 is provided with a tapered hole 8 , and the taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com