Pipe arranging machine for automatic bobbin winder

An automatic winder and management machine technology, applied in the field of management machines, can solve the problems of inconvenient installation for enterprises, large equipment footprint, high production, use and maintenance costs, and achieve stable decline, reduced manufacturing and maintenance costs, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The management machine for automatic winder of the present invention will be described in more detail below in conjunction with the schematic diagram, wherein a preferred embodiment of the present invention is represented, it should be understood that those skilled in the art can modify the present invention described here, and still realize the present invention Beneficial effects of the invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

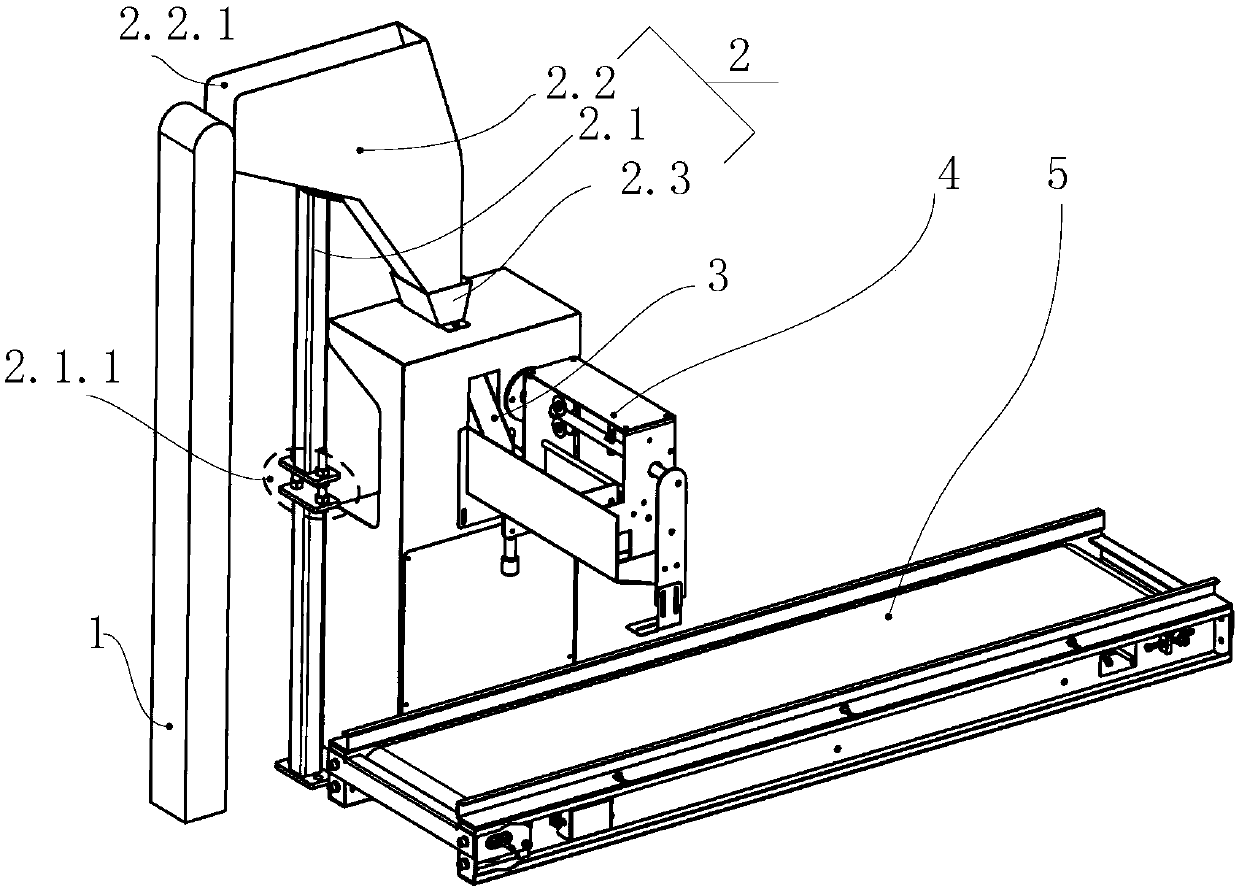

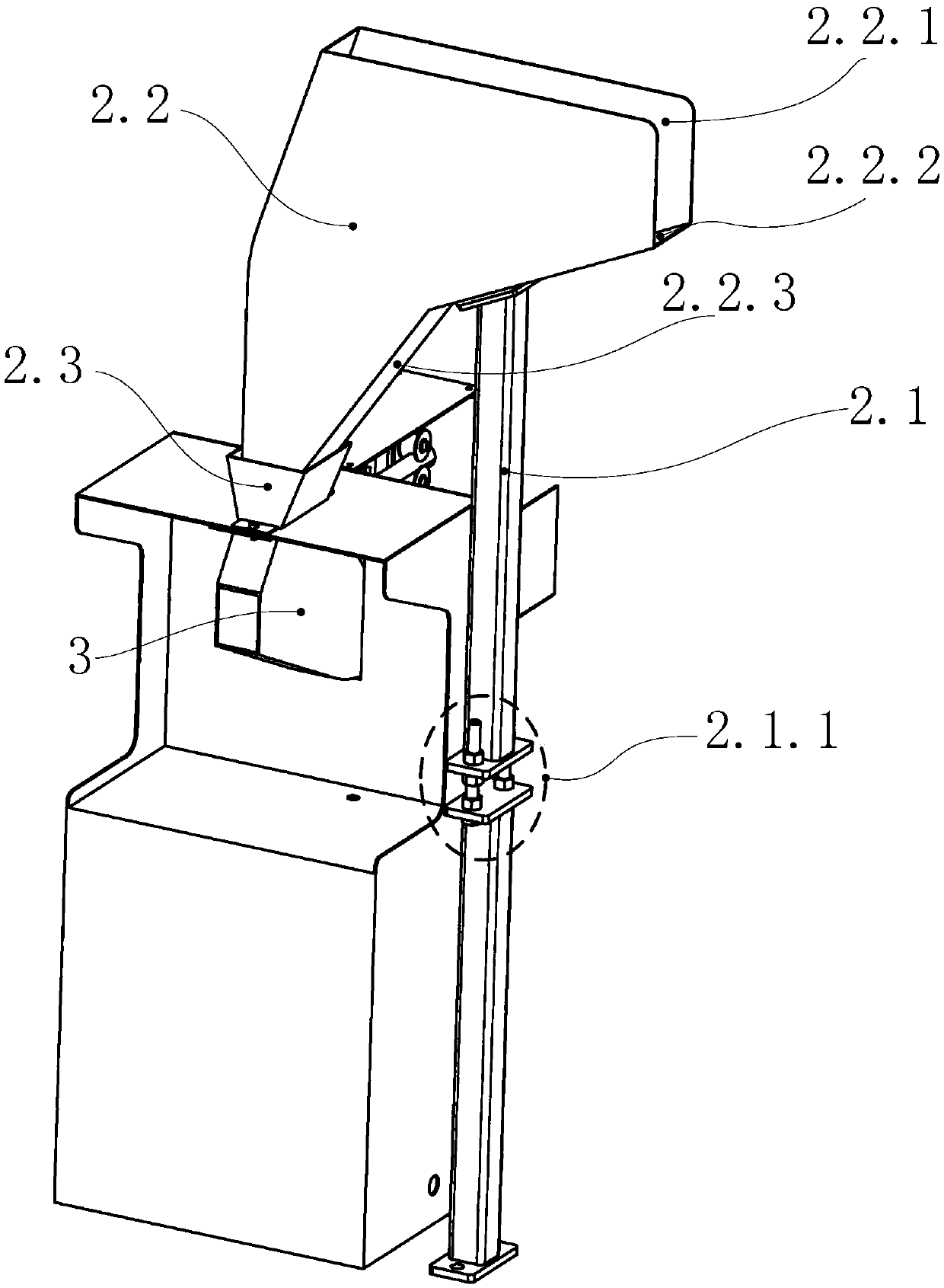

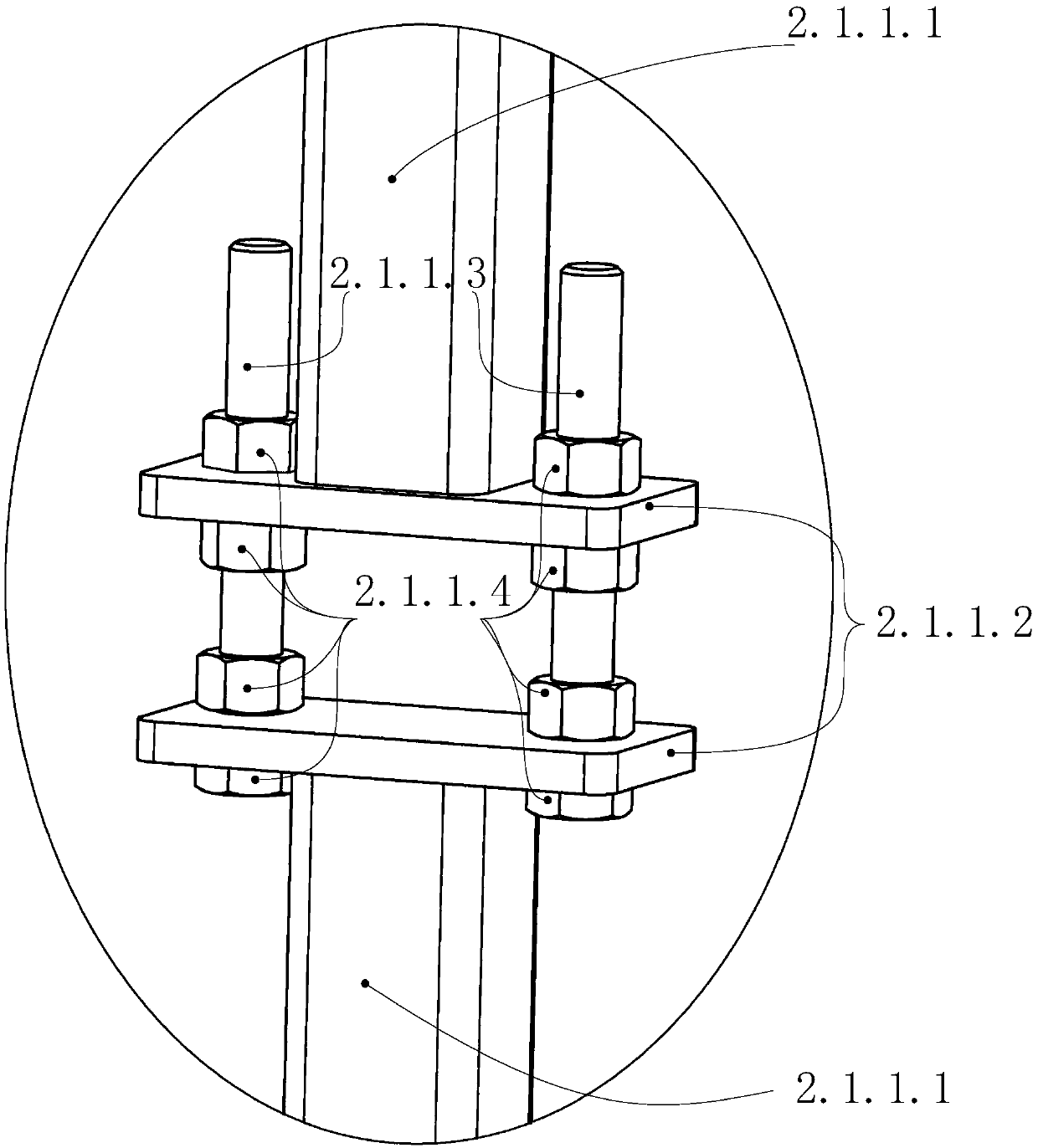

[0064] figure 1 Shown is a schematic diagram of the assembly of the pipe management machine for the automatic winding machine and the bobbin output mechanism of the winding machine according to a preferred embodiment of the present invention; figure 2 Shown is another side schematic view of the overall structure of the management machine for automatic winding machines in a preferred embodiment of the present inven...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap