Polypropylene corrugated pipe composite material and preparation method of composite polypropylene corrugated pipe

A technology of polypropylene and bellows, which is applied in the field of bellows, can solve problems such as insufficient low-temperature impact performance, low softening temperature, and low-temperature brittleness, and achieve the effects of good low-temperature impact resistance, strong heat resistance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

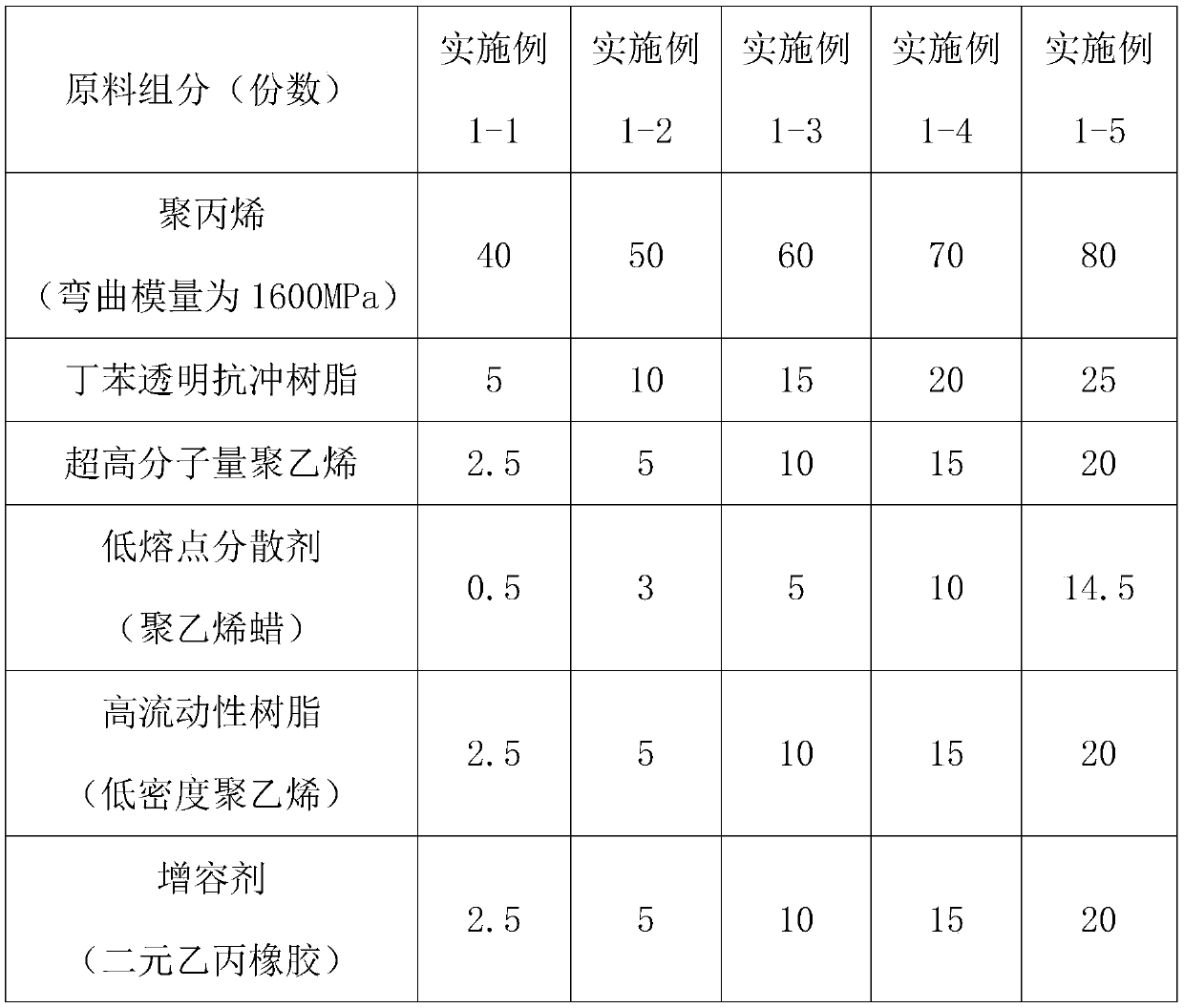

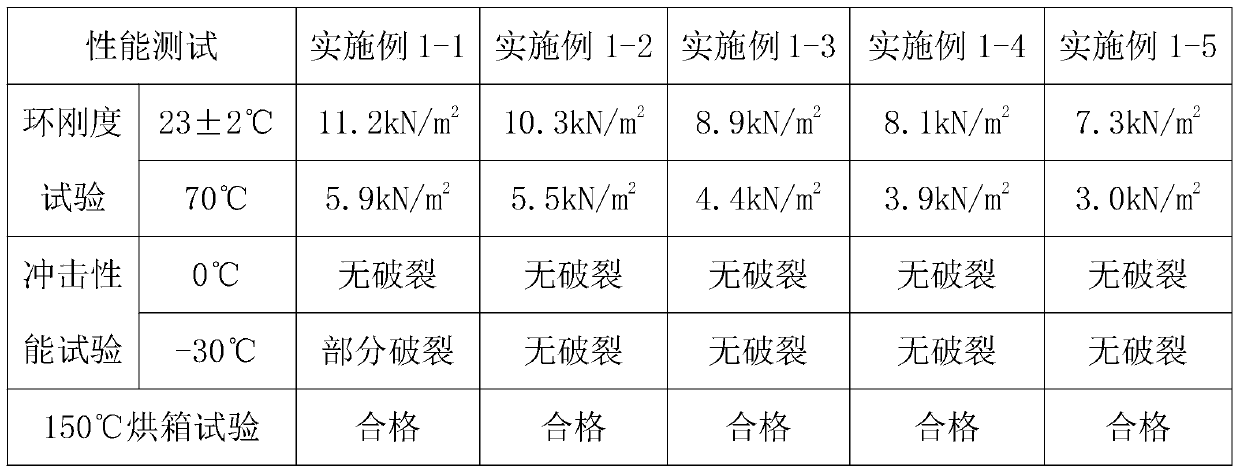

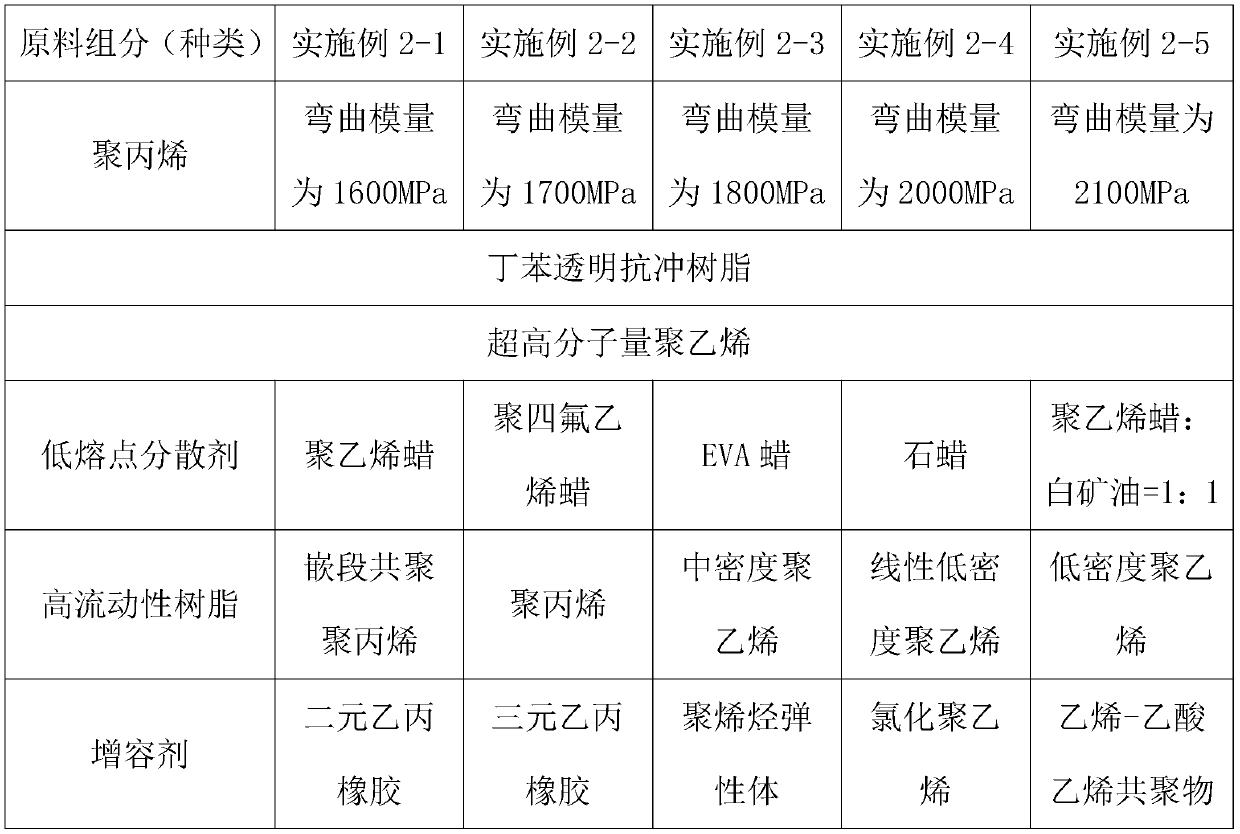

[0024] A polypropylene corrugated pipe composite material, calculated in parts by mass, includes the following raw material components: 50-70 parts of polypropylene, 10-20 parts of styrene-butadiene transparent impact-resistant resin, 5-15 parts of ultra-high molecular weight polyethylene, low 1-10 parts of melting point dispersant, 5-15 parts of high fluidity resin and 5-15 parts of compatibilizer.

[0025] Although the current polypropylene corrugated pipe has the advantages of light weight and high rigidity, it also has the disadvantage of insufficient low-temperature impact performance. Therefore, in order to improve the overall performance of the polypropylene corrugated pipe, under the premise of maintaining high strength, the polypropylene corrugated pipe has the characteristics of strong heat resistance and good low-temperature impact resistance. The transparent anti-impact resin and the ultra-high molecular weight polyethylene are compounded to prepare a polypropylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap