Driving technology of onshore ultra-long PHS oblique pile

A technology of sinking piles and inclined piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., and can solve the problems of inclined pile construction and pile sinking schemes that cannot be carried out on land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

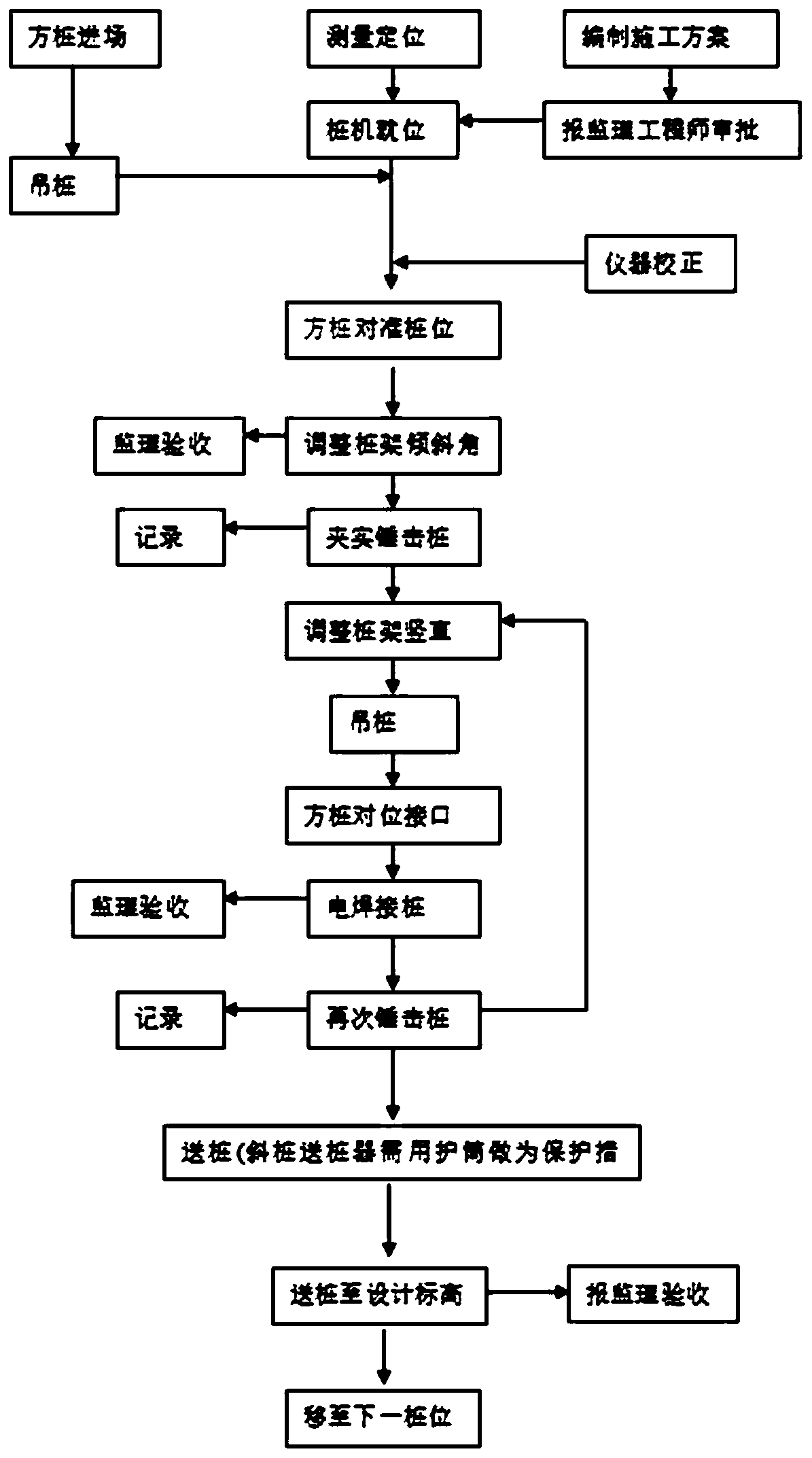

[0026] see figure 1 , which shows the basic flow chart of the construction of super-long PHS inclined piles on land in this example.

[0027] It can be seen from the figure that the construction process of super-long PHS inclined piles on land given in this example mainly includes the following steps:

[0028] (1) Measurement and positioning;

[0029] (2) The pile driver is in place;

[0030] (3) The square pile is aligned with the pile position;

[0031] (4) Adjust the inclination angle of the pile frame;

[0032] (5) Clamping and hammering piles;

[0033] (6) Adjust the pile frame vertically;

[0034] (7) Hoisting;

[0035] (8) Square pile alignment interface;

[0036] (9) electric welding pile;

[0037] (11) Hammering the pile a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com