Printing and dyeing device on color printing packaging production assembly line

An assembly line and color printing technology, applied in the direction of packaging, etc., can solve the problems of printing and dyeing misalignment, easy flow of dye solution, loss of position, etc., achieve direct and effective drying effect, improve printing and dyeing fastness, and beautiful outer packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

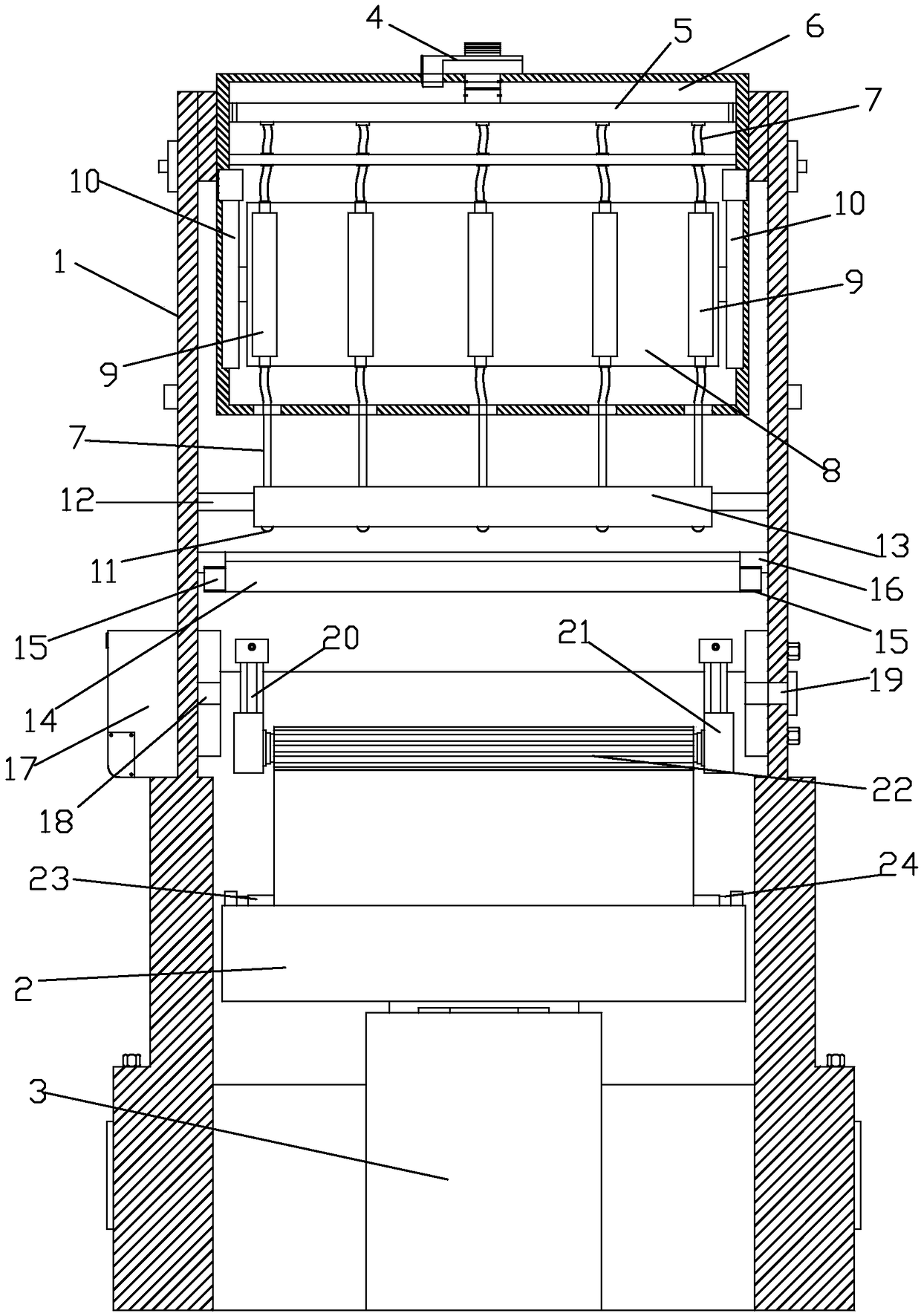

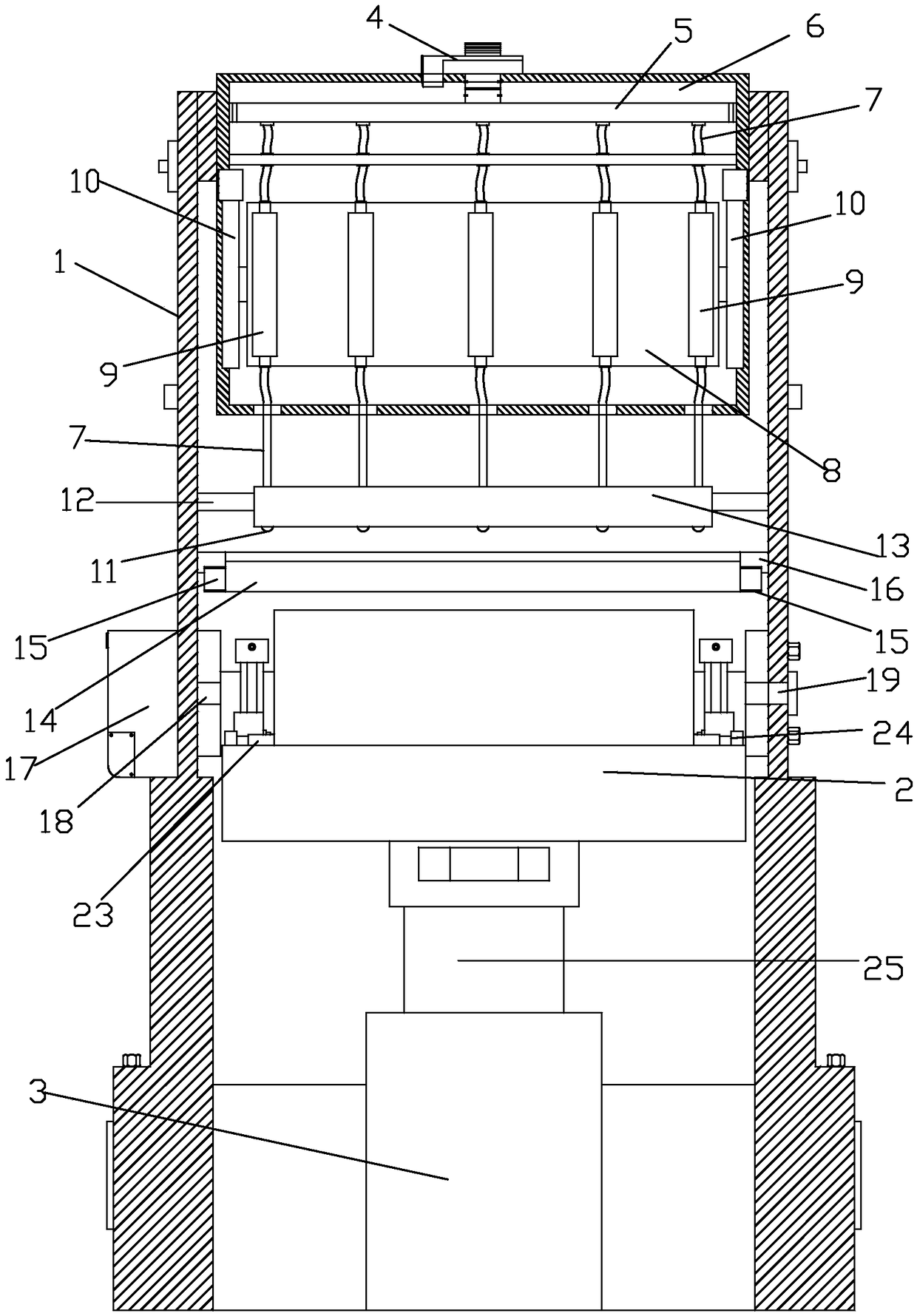

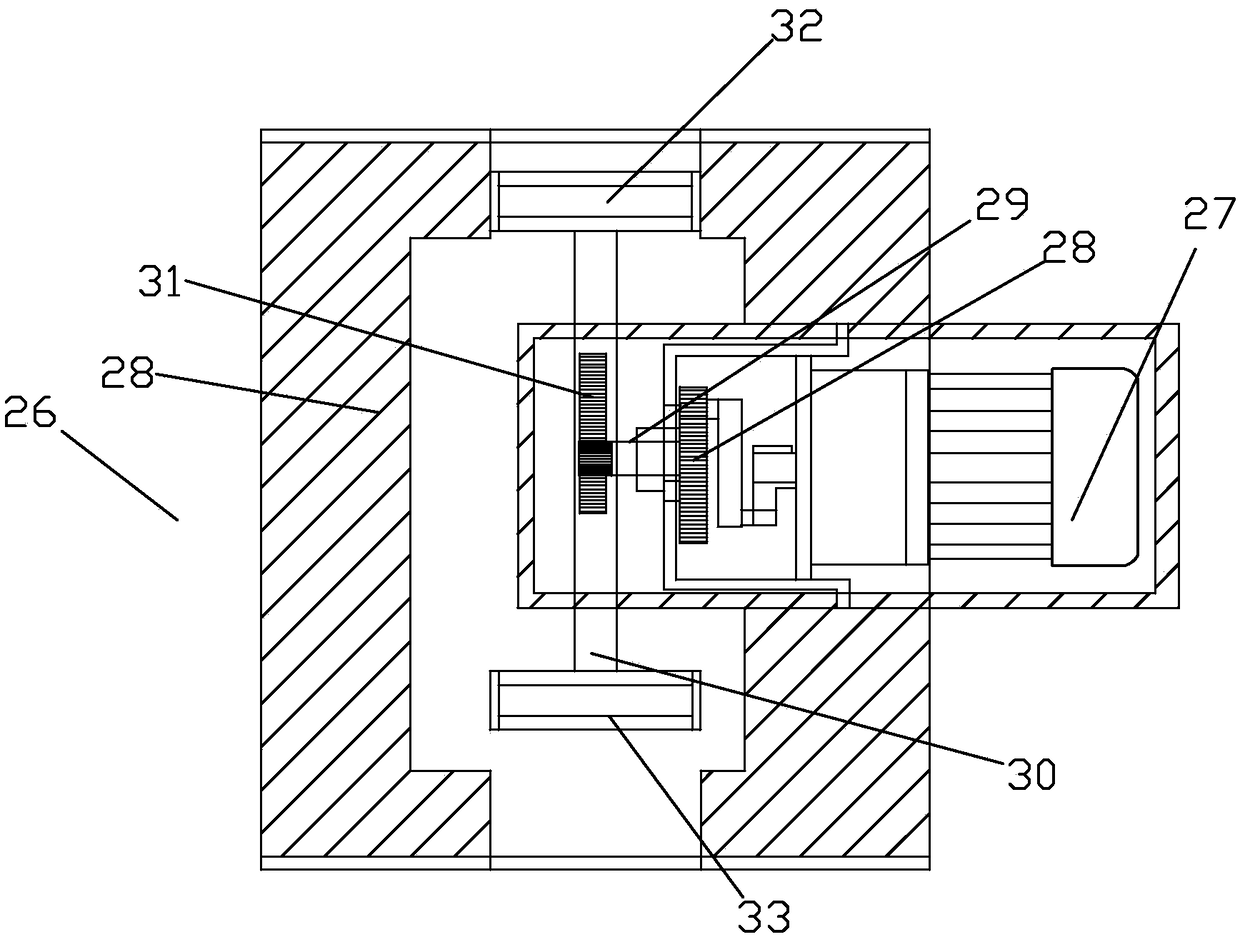

[0033] Such as Figure 1 to Figure 6 As shown, a printing and dyeing device on a color printing and packaging production line includes a casing 1 and a machine 2. The machine 2 is installed in the casing 1. The front and rear ends of the casing 1 are partially open structures. The machine The front and rear of 2 are equipped with assembly line conveyor belts, and the product packaging is first pushed onto machine 2 from the front assembly line conveyor belt; after printing and dyeing is completed, the product packaging is pushed from machine 2 to the rear assembly line conveyor belt, such as cyclical Continuous printing and dyeing operations can be carried out on product packaging, which greatly improves the printing and dyeing efficiency.

[0034]The upper end of the casing 1 is equipped with a dye solution tank 6, the dye solution tank 6 is provided with a liquid inlet 4, a liquid distribution pipe 5, a liquid distribution box 9 and a hose 7, and the liquid inlet 4 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com