Preparation method of degradable cement structure joint filling and separation composite material

A composite material and structure technology, which is applied in building thermal insulation materials, building structures, buildings, etc., to achieve the effect of prolonging service life, simple preparation process, and ensuring existing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

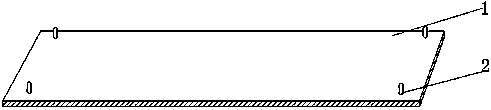

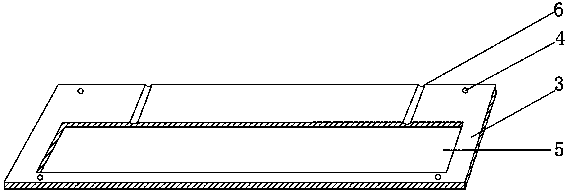

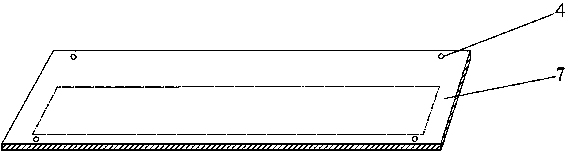

Image

Examples

preparation example Construction

[0044] A preparation method of a degradable cement structure joint-filling and isolation composite material. The components of the preparation method are counted in parts by mass, and the steps are as follows:

[0045] 1) Preparation of plant powder main composite plate components

[0046] At room temperature, first mix 50-42 parts of plant micropowder with 46-50 parts of 40% soluble starch paste and mix evenly, then add 3.5-7 parts of cellulose micropowder and 0.5-1.0 part of superabsorbent resin micropowder for further stirring and mixing . According to the length, width and thickness of the designed plant powder main composite plate, add the above mixture into the mold for molding the plant powder main composite plate. The inner surface of the mold is coated with LUBKO1425 release agent in advance, and pressurized at 110-120 ° C. Molding, the pressure is 20-25MPa, and after 30 minutes, the temperature is lowered and the mold is demoulded to prepare a composite plate with a...

Embodiment 1

[0062] Implement a preparation method of a degradable cement structure joint-filling and isolation composite material, the components of the preparation method are counted in parts by mass, and the steps are as follows:

[0063] 1) Preparation of plant powder main composite plate components

[0064] At room temperature, 50 parts of vegetable powder and 46 parts of 40% soluble starch paste were first stirred and mixed evenly, and then 3.5 parts of cellulose micropowder and 0.5 part of superabsorbent resin powder were added and further stirred and mixed evenly. According to the length, width and thickness of the designed plant powder main composite plate, add the above mixture into the mold for molding the plant powder main composite plate. The inner surface of the mold is coated with LUBKO1425 release agent in advance, and pressurized at 110-120 ° C. Molding, the pressure is 20-25MPa, and after 30 minutes, the temperature is lowered and the mold is demoulded to prepare a compo...

Embodiment 2

[0074] Implement a preparation method of a degradable cement structure joint-filling and isolation composite material, the components of the preparation method are counted in parts by mass, and the steps are as follows:

[0075] Preparation of composite board components with vegetable powder as the main body

[0076] At room temperature, 42 parts of plant micropowder and 50 parts of 40% soluble starch paste were stirred and mixed evenly, and then 7 parts of cellulose micropowder and 1 part of superabsorbent resin micropowder were added to further stir and mix evenly. According to the length, width and thickness of the designed plant powder main composite plate, add the above mixture into the mold for molding the plant powder main composite plate. The inner surface of the mold is coated with LUBKO1425 release agent in advance, and pressurized at 110-120 ° C. Molding, the pressure is 20-25MPa, and after 30 minutes, the temperature is lowered and the mold is demoulded to prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com