Hydraulic engineering sludge pipeline dredging device

A technology for water conservancy projects and sludge, which is applied in the field of dredging equipment for sludge pipelines in water conservancy projects, can solve problems such as blockage and reduced pipe diameter, and achieve the effect of preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

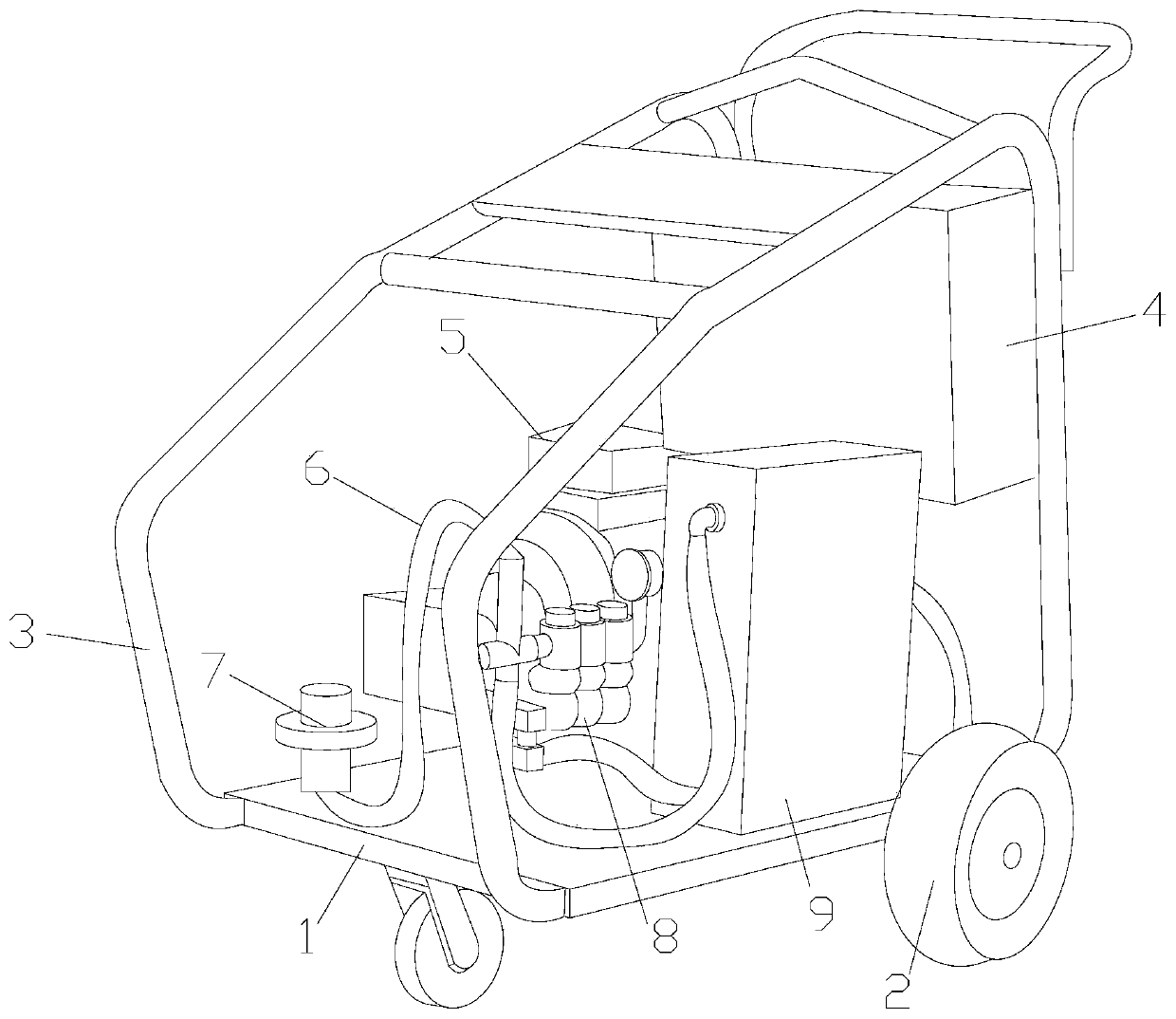

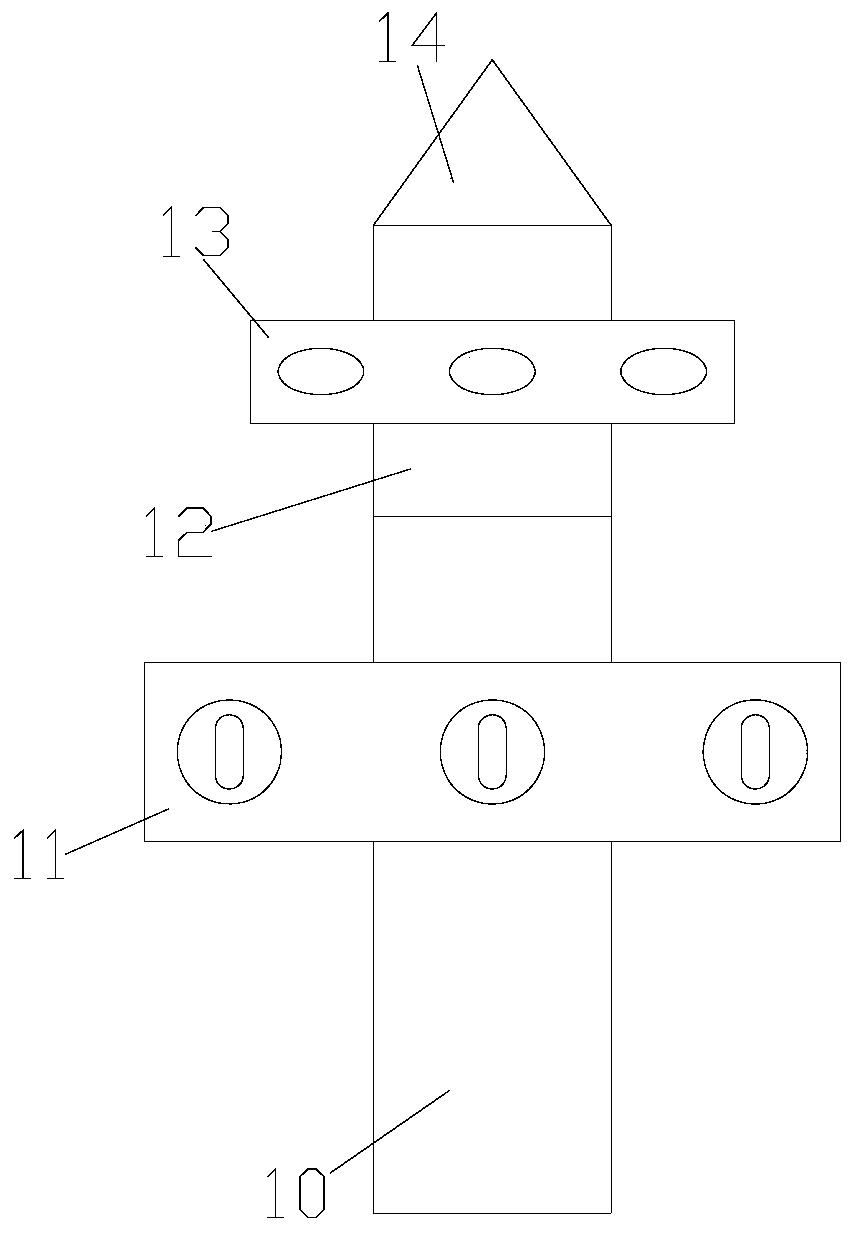

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution for dredging equipment for sludge pipelines in hydraulic projects: its structure includes a bottom plate 1, a moving wheel 2, a protective frame 3, a power box 4, a power machine 5, a gas pipe 6, a dredging mechanism 7, a valve 8, and a pressure box 9 , the bottom of the bottom plate 1 is equipped with a moving wheel 2 and a protective frame 3 is welded above the top, the power supply box 4 is installed on the protective frame 3 and is electrically connected with the power machine 5, and the power machine 5 and the pressure box are installed on the bottom plate 1 9. The pressure tank 9 is connected to the power machine 5 through the valve 8, the dredging mechanism 7 is connected to the valve 8 through the air pipe 6, and the dredging mechanism 7 is composed of a connecting pipe 10, a stabilizing device 11, a rotator 12, The device 13 and the cone head 14 are composed. The connecting pipe 10 is ...

Embodiment 2

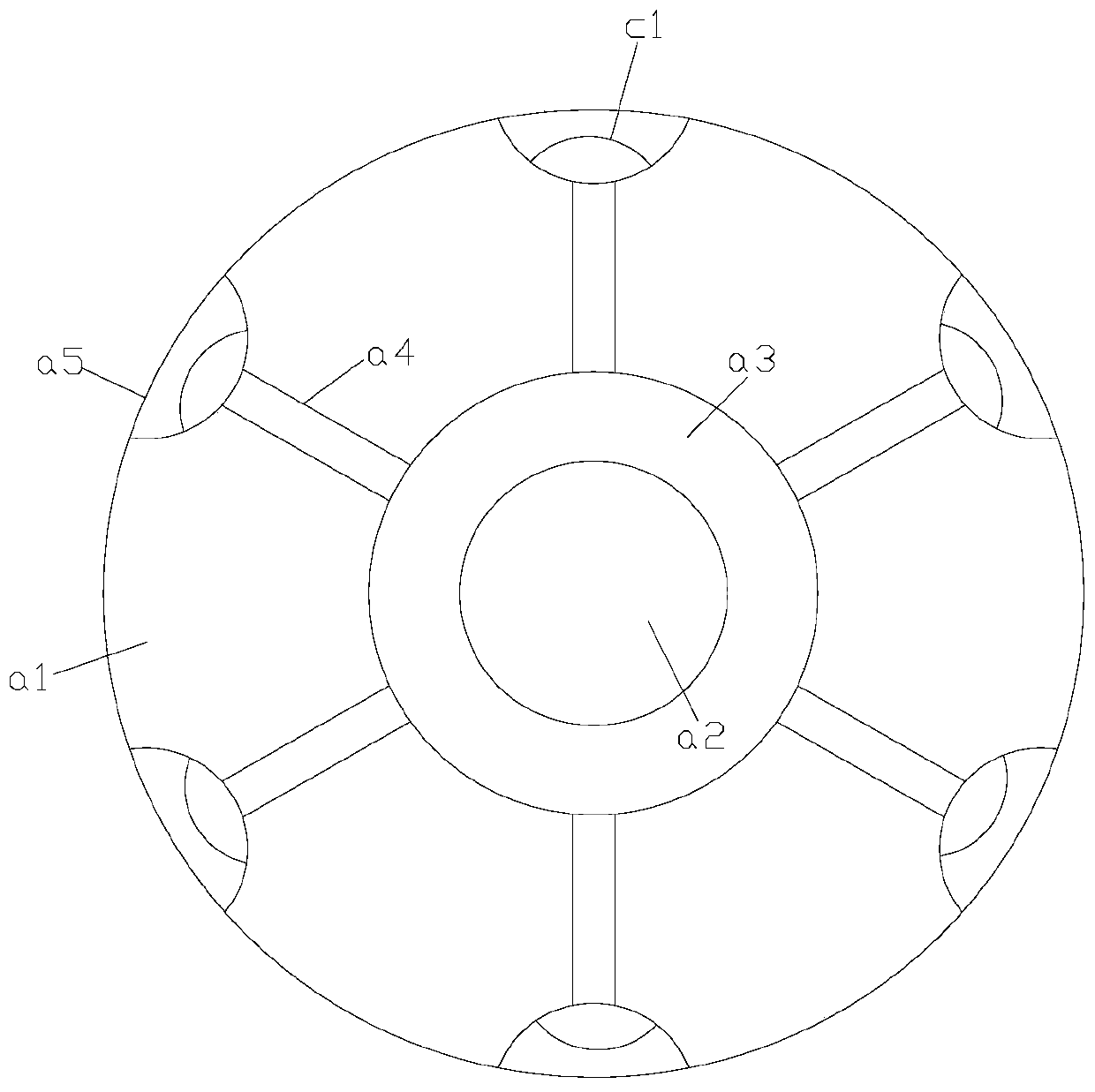

[0027] Such as Figure 5 As shown, on the basis of Embodiment 1, it is also included that the stabilizing device 11 is composed of a support plate b1, a jack b2, and an air inlet b3, the middle of the support plate b1 is connected with the air intake pipe a2, and the support There are six sets of jacks b2 on the disk b1, the bottom of the jacks b2 is connected to the intake pipe a2 through the air inlet b3, and the jacks b2 are composed of telescopic cylinder e1, push rod e2, pulley e3 , arc-shaped groove e4, the telescopic cylinder e1 is provided with a top push rod e2, and the end surface of the push rod e2 away from the telescopic cylinder e1 has an arc-shaped groove e4 and a pulley e3 is installed inside the arc-shaped groove e4 .

[0028] Before the screw breaking device 13 breaks up the sludge, the high-pressure airflow enters the intake pipe a2, a part of the airflow of the intake pipe a2 enters the jack b2 through the air inlet b3, and the telescopic cylinder e1 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com