Quick release type double-shaft hinge mechanism

A biaxial hinge and hinge mechanism technology, which is applied in the direction of pivot connection, etc., can solve the problems of limited deployment and retraction, single function of hinge or hinge, and fixed and rigid connection method, so as to achieve safe and reliable locking effect , simple operation, no risk of loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

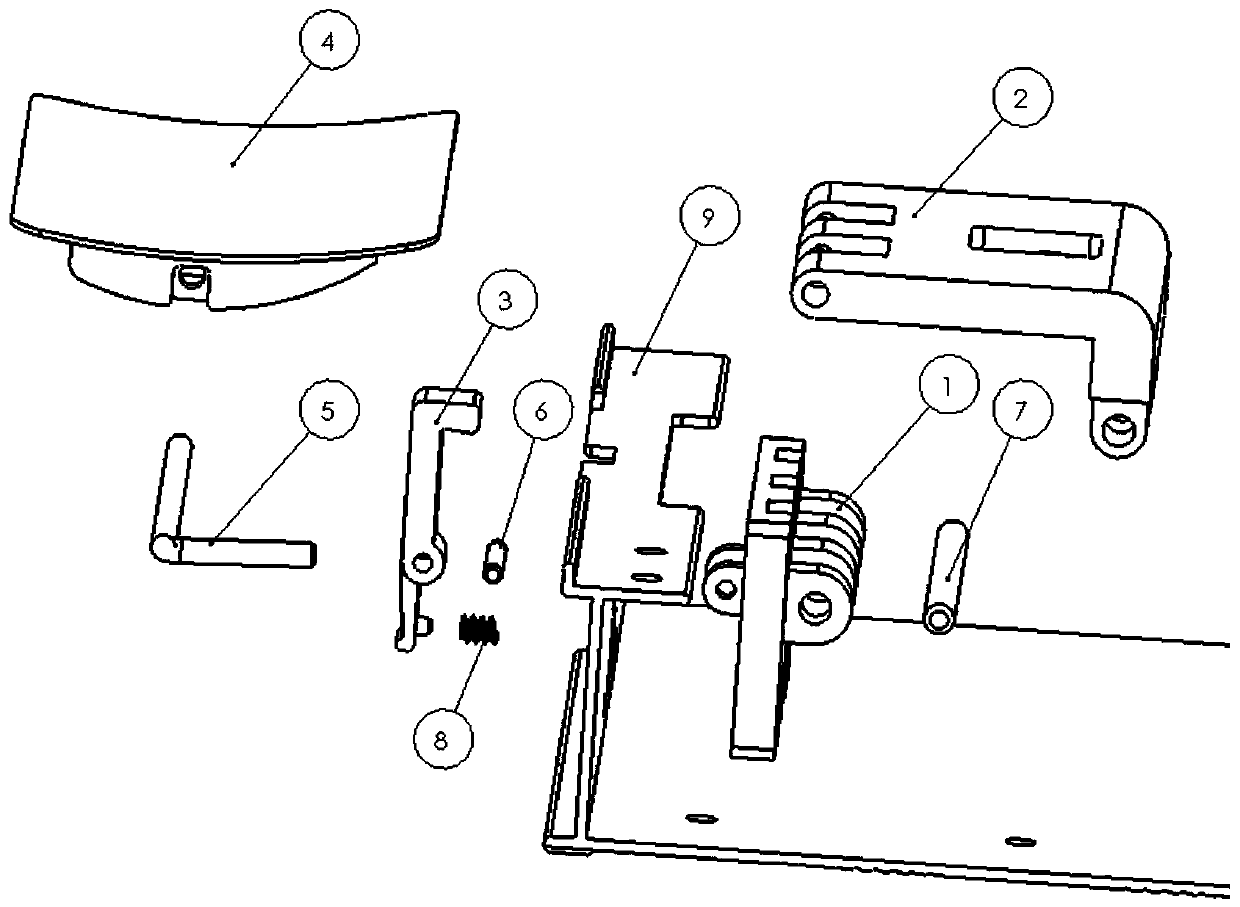

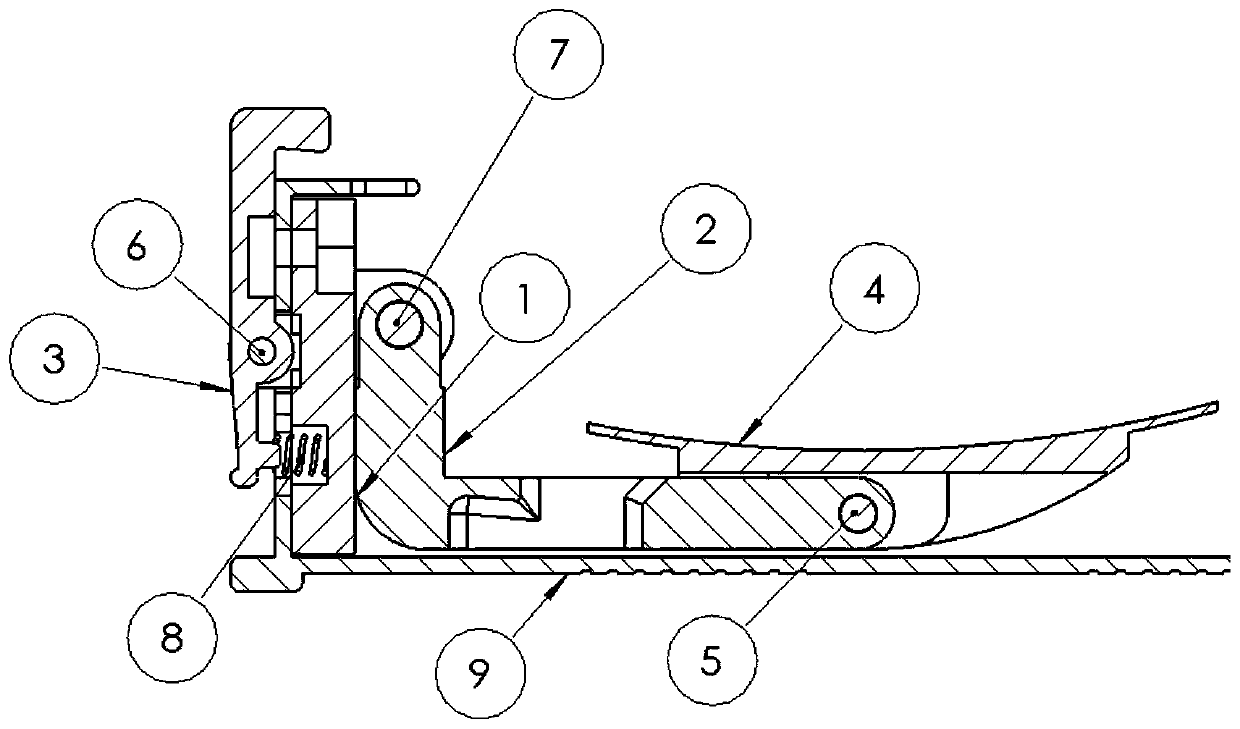

[0056] Such as Figure 1-5 As shown, a quick-release hinge turning and locking mechanism of the present invention mainly includes a hinge fixing block 1, a hinge 2, an external connection piece 4, a pivot pin 5, a mounting pin 6, a hinge pivot 7, and a fixed plate 9. In addition, it also includes a hanging fastener 3 and a spring 8.

[0057] The hanging fastener 3 has a strip shape, and one end of the hanging fastener 3 forms an L-shaped short hook. On the other end of the hook 3, a spring fixing portion is provided on the same side as the extension direction of the short hook portion, and the spring fixing portion may be a protrusion or a groove of a suitable shape. On the other end part, on the same side as the spring fixing part, a hinge seat for the mounting pin 6 to pass through is provided between the short hook part and the spring fixing part. The shape of the hinge seat is matched with the aforementioned mounting pin seat and can receive the mounting pin 6 to pass throug...

Embodiment 3

[0072] The hinge mechanism in this embodiment is different from the first embodiment or the second embodiment only in the structure of the pivot pin 5, and is an improved preferred embodiment.

[0073] See attached Figure 7 with 8 As shown, in this embodiment, the pivot pin 5 is L-shaped. The pivot pin 5 is configured to be able to rotate or be rotated in the pivot pin seat on the external connector 4 and the pivot pin hole at one of the folded ends of the hinge 2, and can be withdrawn, The external connector 4 and the hinge 2 can be quickly disassembled.

[0074] The "L shape" is used to facilitate the rotation operation and the insertion and removal operation of the pivot pin 5, so as to realize the quick connection or disassembly of the hinge mechanism of the present invention and the external connection piece 4. When the pivot pin 5 is inserted in place, the end of the pivot pin 5 is rotated to the left or right to be close to the external connector 4 to prevent it from being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com