Sinking-type installation device of gear box of large drilling rig

A gear box, submerged technology, used in transmission parts, belts/chains/gears, drilling equipment, etc., can solve problems such as bolt extrusion deformation, prevent extrusion deformation, improve safety, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

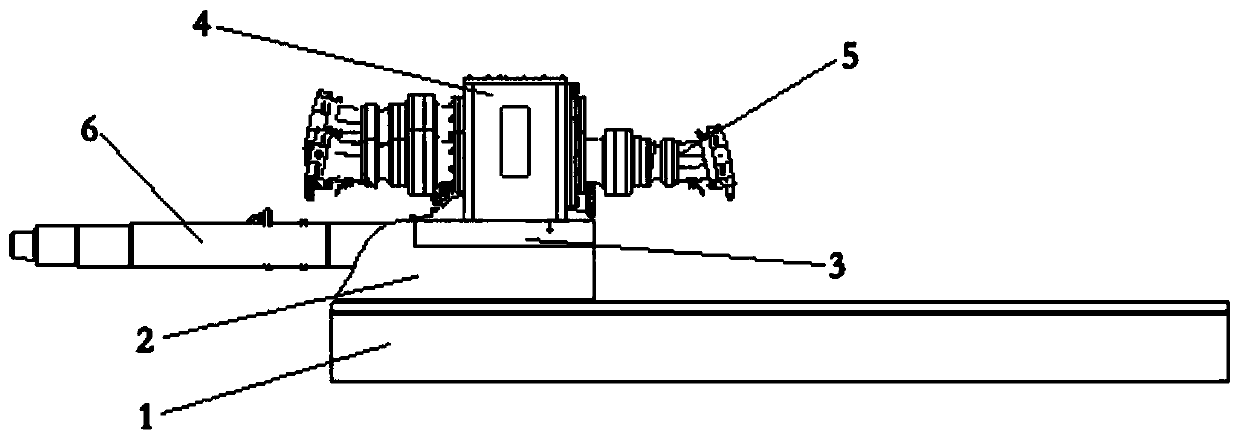

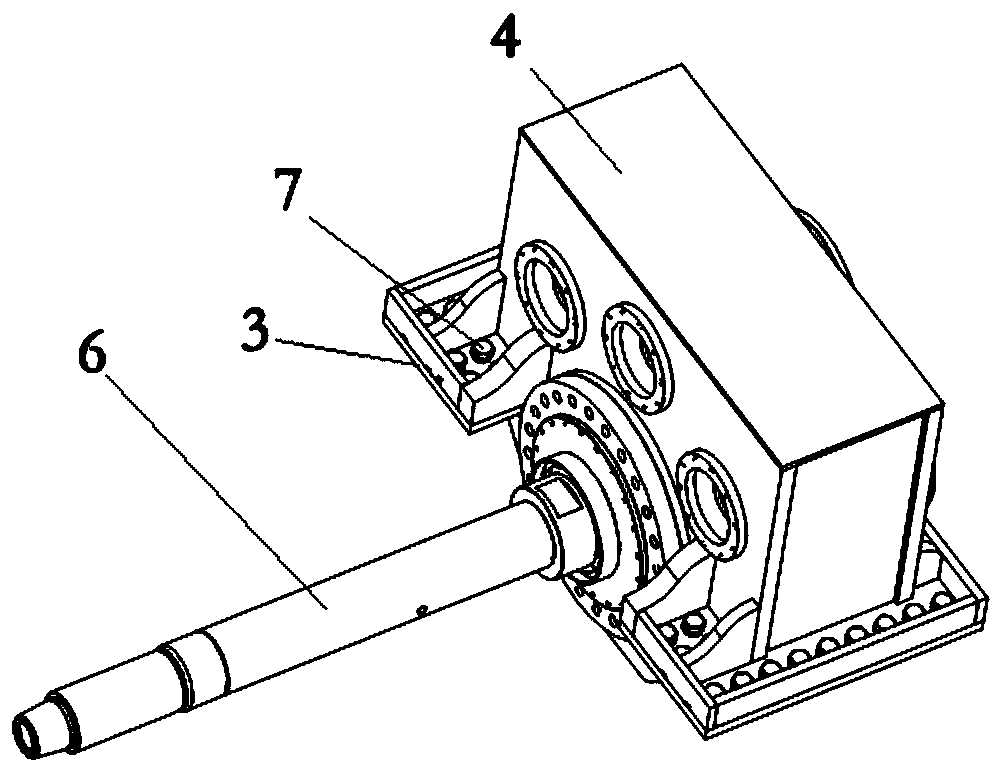

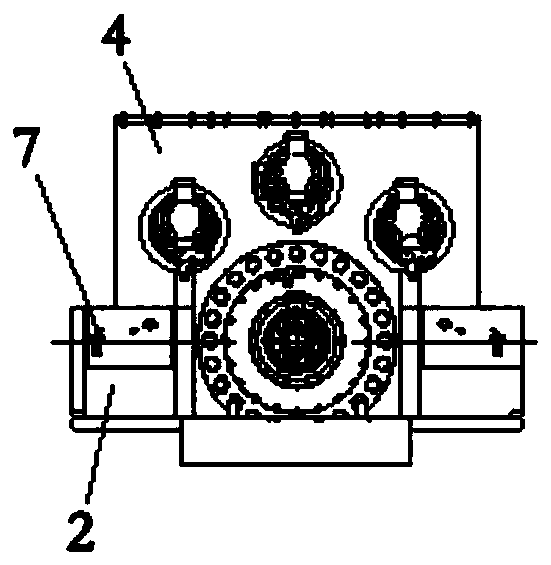

[0023] see figure 1 , figure 2 and image 3 , figure 1 It is a schematic diagram of a gear box submerged installation device for a large drilling rig. figure 2 is a three-dimensional diagram of the gearbox, image 3 is the left view of the gearbox, Figure 4 It is a schematic top view of the gear box submerged installation device;

[0024] A gear box sinking installation device for a large drilling rig, characterized in that it includes a push-pull seat panel 1, a push-pull seat mounting plate 2, a power head mounting plate 3, a gear box 4, a rotating motor 5 and a power head shaft 6; The push-pull seat mounting plate 2 is installed above the push-pull seat panel 1 and is close to one end of the push-pull seat panel 1; the power head mounting plate 3 is installed above the push-pull seat mounting plate 2; the gear box 4 installed on the power head mounting plate 3;

[0025] The gear box 4 includes a rotary motor 5, a box body, and gears located in the box body; one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com