Vibration damping and energy dissipation limiting device for water diversion steel pipe bearing of hydropower station

A technology of water diversion steel pipe and limit device, which is applied in the direction of hydropower station, traditional hydropower energy, hydropower generation, etc. The effect of reducing earthquake damage and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

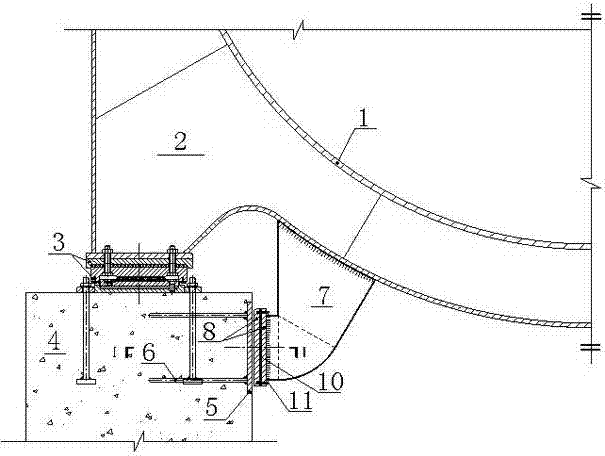

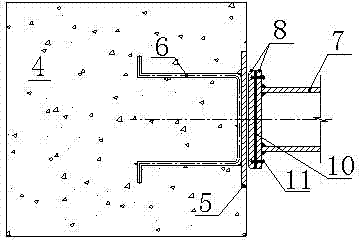

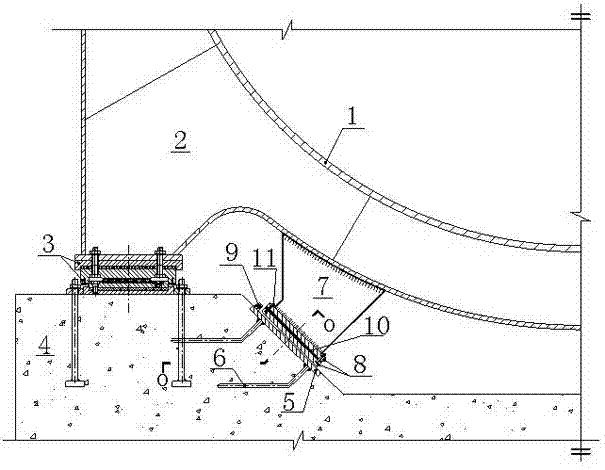

Method used

Image

Examples

Embodiment 1

[0021] Example 1. Repair of lateral displacement of water diversion steel pipes in a certain project in Ethiopia

[0022] 1.1 Project overview

[0023] The project is located on the Neshe River in the Blue Nile River Basin, 250km northwest of Addis Ababa, the capital of Ethiopia, at 9°43ˊ~9°46ˊ north latitude and 37°5ˊ~37°16ˊ east longitude. The power station is a peak-shaving power station, which runs for 6.5 hours a day. A total of 2 bucket-type hydro-generator sets are installed, with a gross water head of 614.5m, a single-unit capacity of 48.5MW, a total installed capacity of 97MW, and a single-unit rated reference flow rate of 9.25m 3 / s, the designed annual generating capacity is 215.5 million kW·h.

[0024] The main buildings of this project are mainly composed of dams, spillways, water diversion systems, ground powerhouses and outlet yards. The dam adopts a homogeneous earth dam, with a crest elevation of 2235.0m, a maximum dam height of 38m, a normal storage lev...

Embodiment 2

[0031] Example 2, a dam and power station project in Iran

[0032] A dam and power station project in Iran is located on the Rudbar River in the Zagros Mountains of Lorestan Province in western Iran, about 454km away from the capital Tehran. The power station is a diversion-type power station under complex geological conditions in high earthquake areas. The project consists of major buildings such as dams, spillways, dam body discharge holes, water delivery systems, ground powerhouses and switch stations. The power station has 2 installed units, with a single unit capacity of 225MW, a rated water head of 430.74m, and a rated flow rate of 115.6m 3 / s. The water diversion tunnel has a diameter of 6.0m and a length of about 1.34km. The lengths of double-line ① and ② open-pipe steel pipes are about 2.34km and 2.32km, and the diameters range from 4.4m to 4.0m, 3.8m, and 3.4m. Steel pipes pass through different terrain areas such as steep slopes, gentle slopes, tunnels and gulli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com