Bridge deck pavement structure based on high-performance rubber concrete

A rubber concrete and bridge deck pavement technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of reduced service life of structures, increased maintenance costs, fatigue damage, etc., to achieve extended service life, high flexural strength, Effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

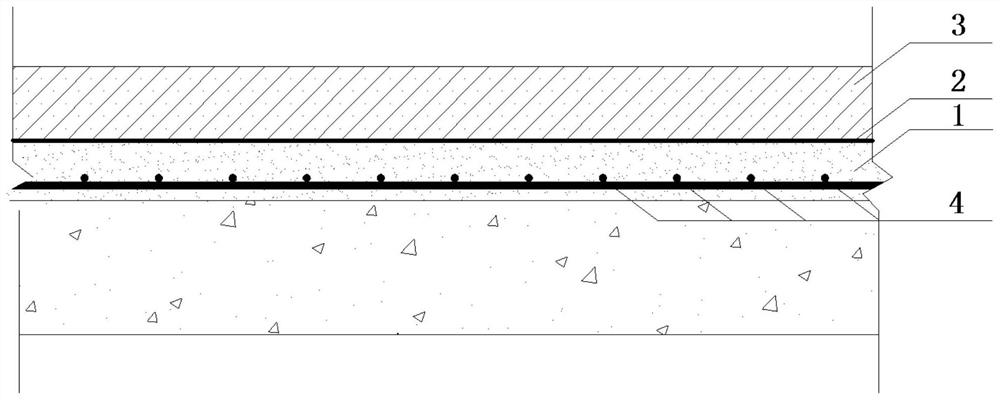

[0035] Such as figure 1 As shown, a bridge deck pavement structure based on high-performance rubber concrete, including rubber cement concrete cast-in-place layer 1 laid on the bridge surface from bottom to top, SBR modified emulsified asphalt waterproof layer 2 and asphalt concrete surface layer 3 , the rubber cement concrete cast-in-place layer 1 is preset with a single-layer two-way steel mesh 4 in the tension zone, and the rubber cement concrete cast-in-place layer 1 on the bridge surface, the SBR modified emulsified asphalt waterproof layer 2 and the asphalt concrete surface layer 3 are total The thickness is 16.3cm;

[0036] Among them, the asphalt concrete surface layer 3 adopts SMA-13 gradation, the porosity is 3.5%, and the thickness is 8.0cm;

[0037] The dosage of SBR modified emulsified asphalt in SBR modified emulsified asphalt waterproof layer 2 is 0.5kg / m 2 ;

[0038] Rubber cement concrete cast-in-place layer 1 uses rubber particles with a particle size of...

Embodiment 2

[0041] Such as figure 1 As shown, a bridge deck pavement structure based on high-performance rubber concrete, including rubber cement concrete cast-in-place layer 1 laid on the bridge surface from bottom to top, SBR modified emulsified asphalt waterproof layer 2 and asphalt concrete surface layer 3 , the rubber cement concrete cast-in-place layer 1 is preset with a single-layer two-way steel mesh 4 in the tension zone, and the rubber cement concrete cast-in-place layer 1 on the bridge surface, the SBR modified emulsified asphalt waterproof layer 2 and the asphalt concrete surface layer 3 are total The thickness is 18.3cm;

[0042] Among them, the asphalt concrete surface layer 3 adopts SMA-16 gradation, the porosity is 4.5%, and the thickness is 10.0cm;

[0043] The dosage of SBR modified emulsified asphalt waterproof layer 2 is 0.6kg / m 2 ;

[0044] Rubber cement concrete cast-in-place layer 1 uses rubber particles with a particle size of 1-2mm, and the mixing method is to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com