Synchronous switch valve core with pressure stabilizing function

A technology of synchronous switch and spool, applied in the direction of functional valves, multi-way valves, safety valves, etc., can solve the problems of one-way check valves stuck by impurities, large impact of flow resistance, and poor sealing, so as to prevent cold Effects of hot water channeling, shortened waterway, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

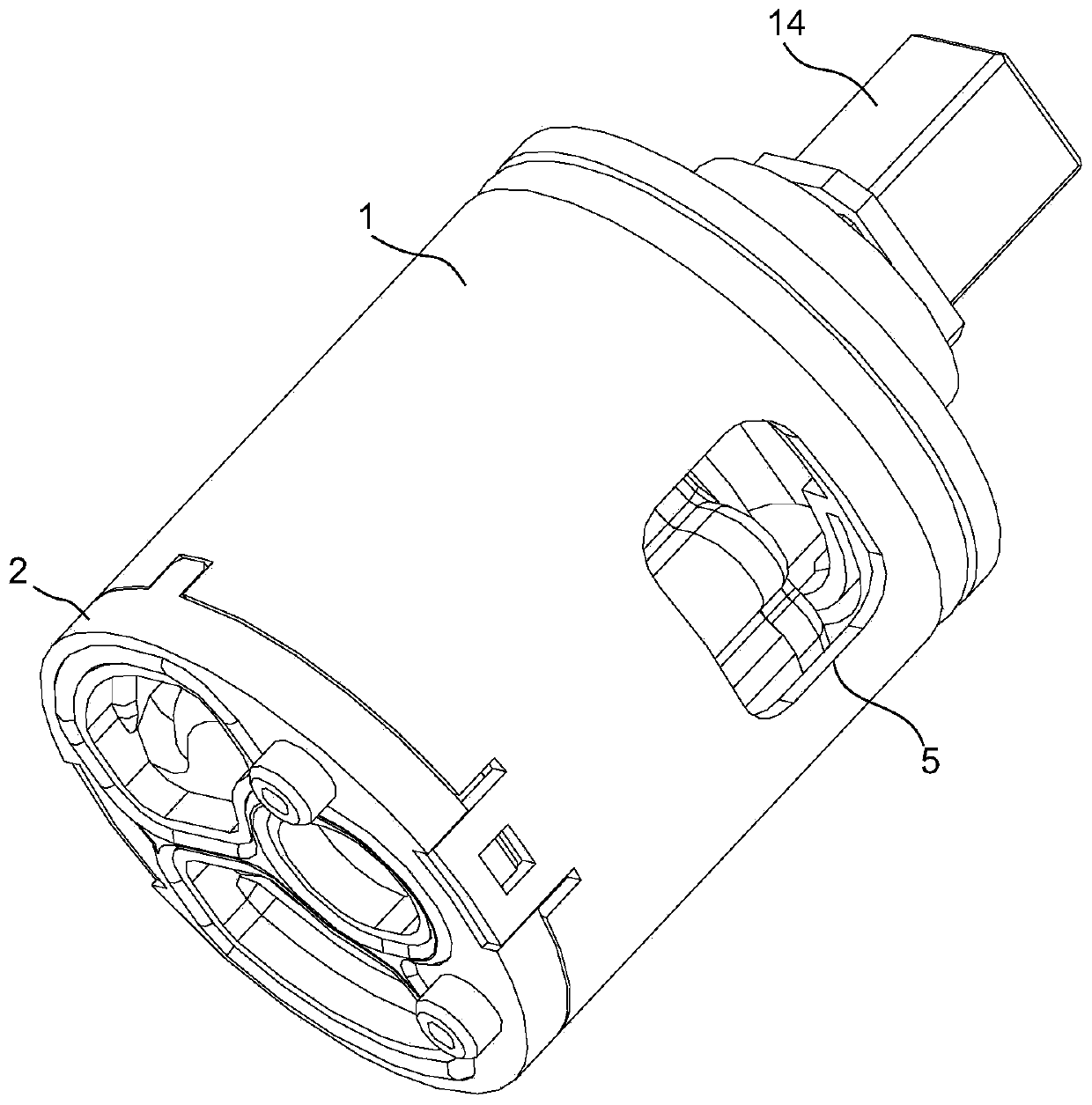

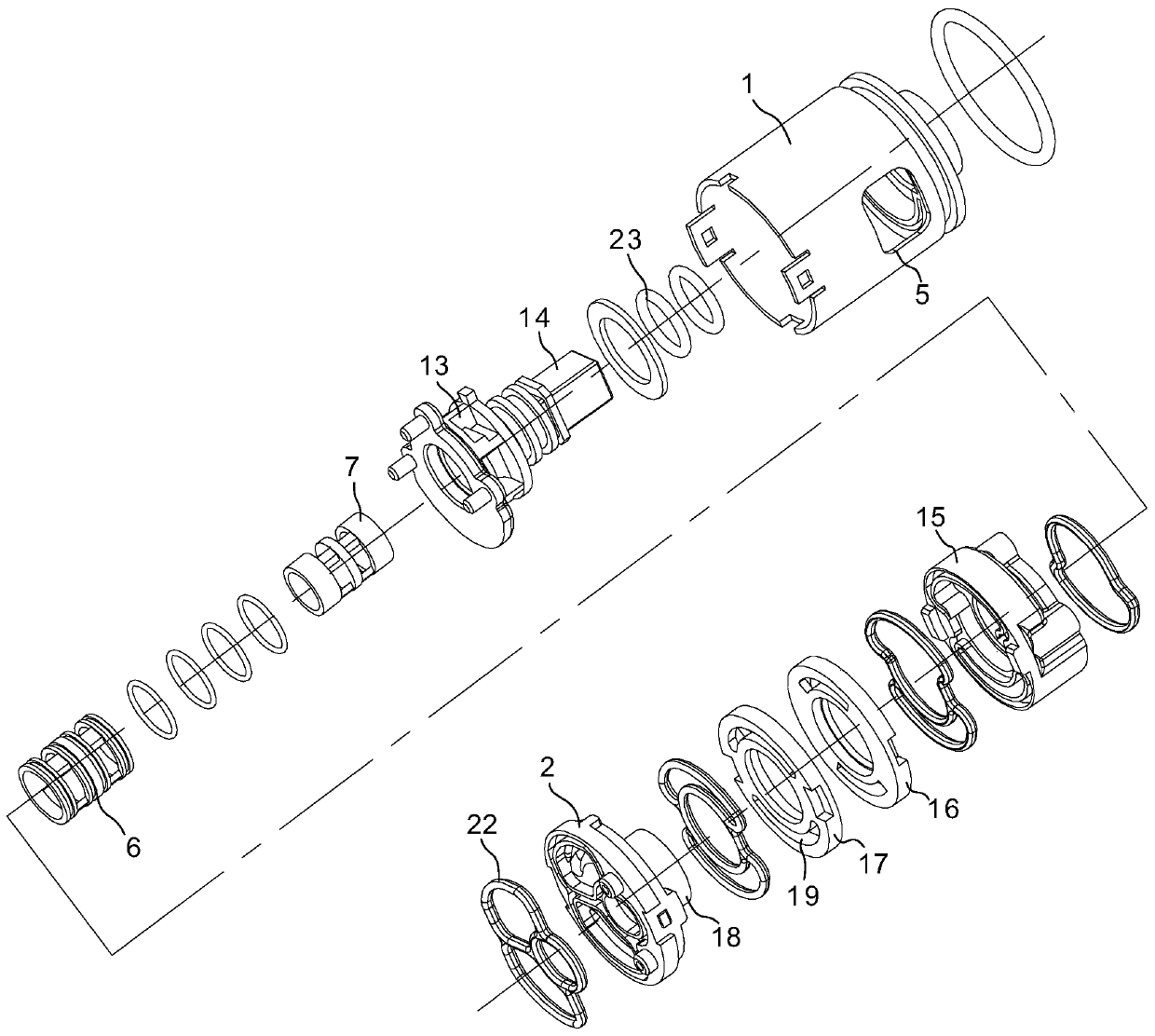

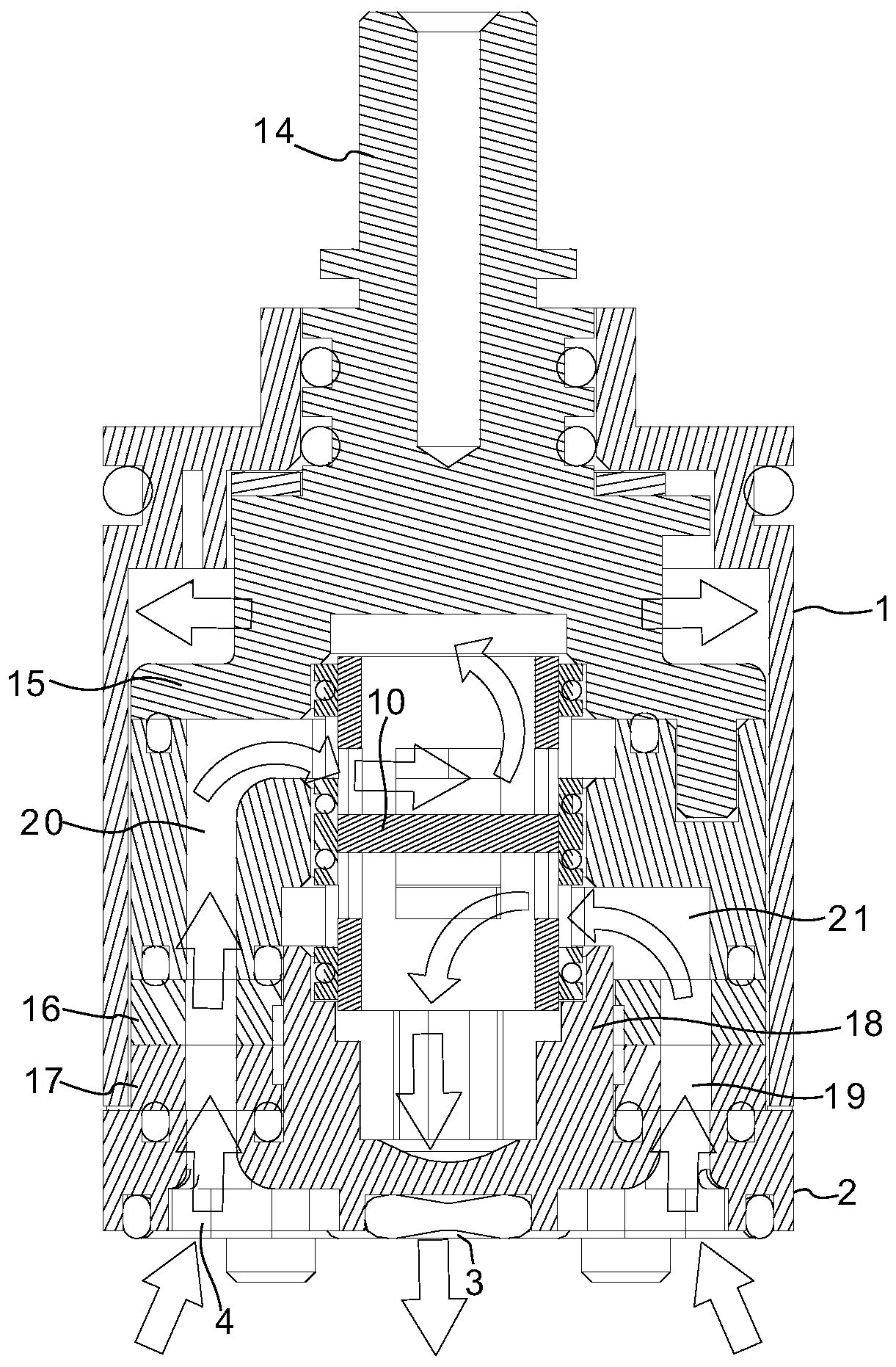

[0020] As shown in the figure, the present invention includes: a valve core housing 1, a valve core base 2, a flow regulating module and a balance hydraulic module, the valve core housing and the valve core base are clamped to form a valve core cavity, the flow regulating module and The balance hydraulic module is coaxially arranged in the cavity of the spool, and the water flow enters the cavity of the spool from one end of the cavity of the spool, passes through the flow regulating module, and then enters the balance hydraulic module. 3 and two water inlets 4, the side wall of the valve core away from the water flow has an upper water outlet 5, and two water flow paths are formed in the valve core, one of which is one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com