Pipeline mold lifting device capable of cyclically utilized and construction method

A technology for pipes and molds, applied in the direction of pipes, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the problems of troublesome handling, poor sealing at the root of pipes, irregular hanging molds of pipes, etc., saving time and effort in operation. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

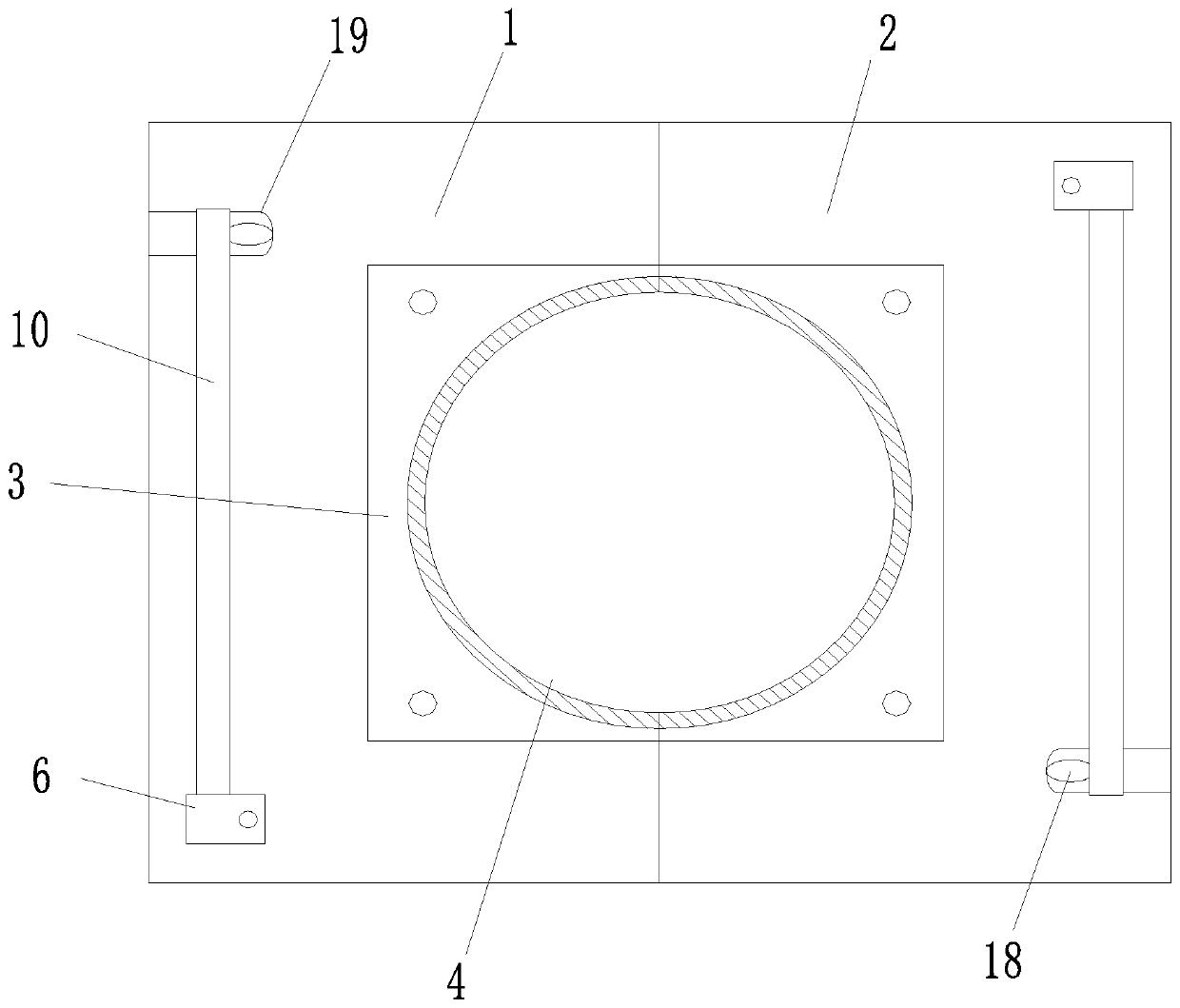

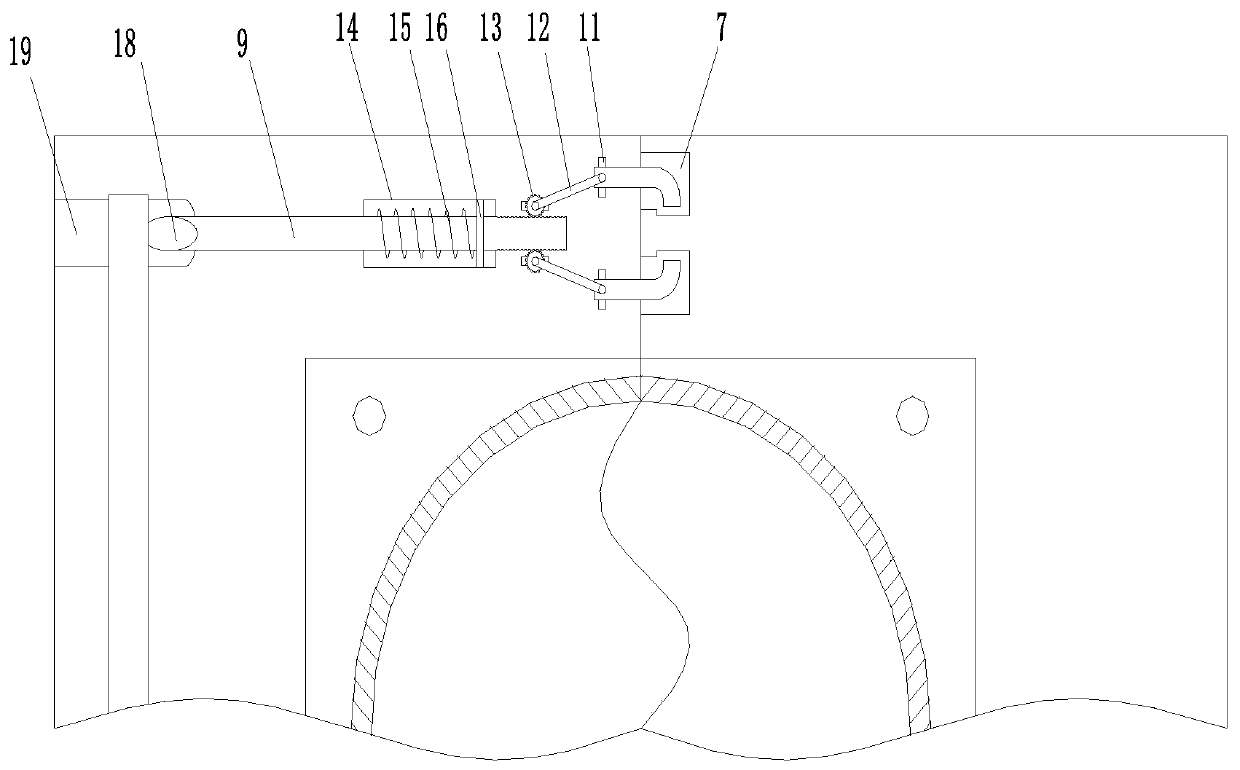

[0025] Such as figure 1 , figure 2 with Figure 4 As shown, a recyclable pipe hanging mold device includes a first assembly 1 and a second assembly 2 that are detachably connected as a whole, the first assembly 1 and the second assembly 2 are made of plastic, The first assembly 1 and the second assembly 2 are centrally symmetrically arranged and both have hollow structures. Both the first assembly 1 and the second assembly 2 are detachably connected with a positioning plate 3 for positioning the pipe by bolts. The opposite side of the positioning plate 3 is provided with semi-circular pipe notches 4, and the side walls of the two pipe notches 4 are equipped with sealing structures. The sealing structure is used to realize the adhesion to the outer wall of the embedded pipe to realize the leakage prevention function. . Both the first assembly 1 and the second assembly 2 are provided with a locking assembly and a positioning groove 7, and the locking assembly on the first assemb...

Embodiment 2

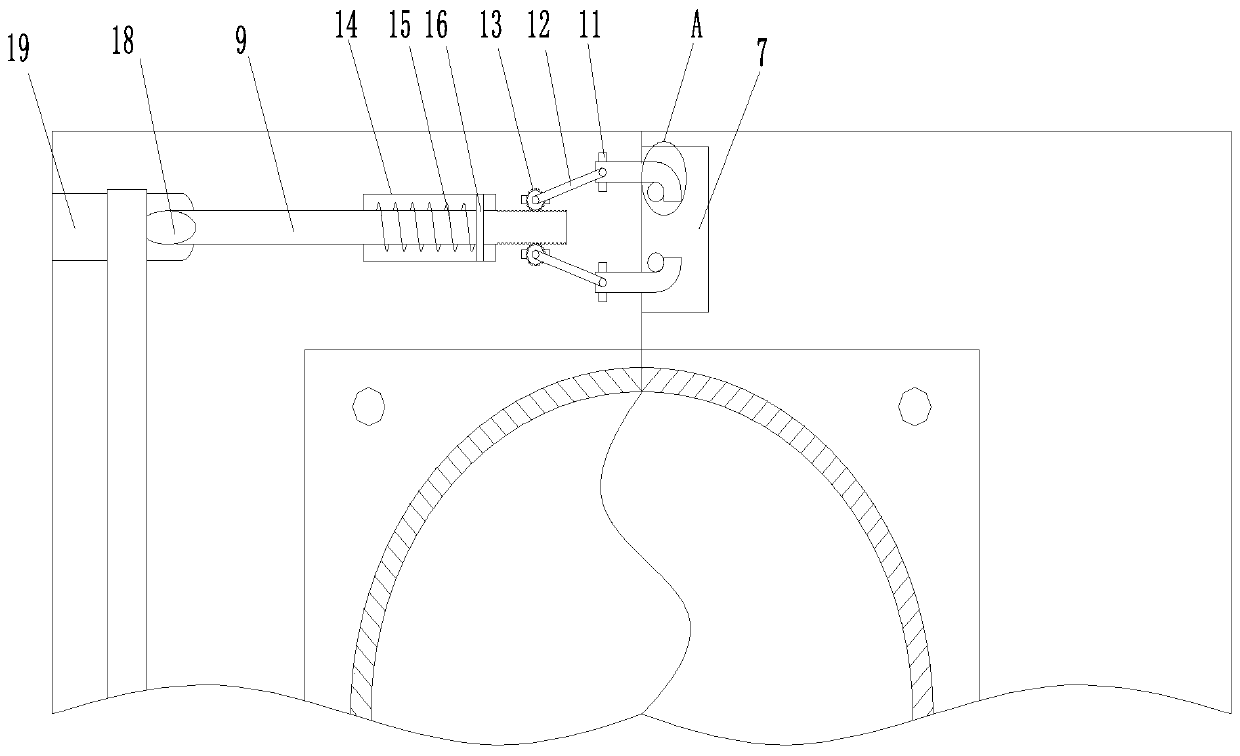

[0029] Such as Figure 3 to Figure 4 As shown, the difference from Embodiment 1 is that the positioning grooves 7 on the first assembly 1 and the second assembly 2 are both provided with a fixing post 20, and the claw 8 is opposite to a side wall of the fixing post 20. Each is provided with an elastic unit, and the elastic unit includes an arc-shaped splint 21 and a compression spring 5, and the arc-shaped splint 21 is connected to the pawl 8 through the compression spring 5. In order to ensure that the first assembly 1 and the second assembly 2 are more effectively and tightly combined into a whole, the arc splint 21 is used to make the arc splint 21 and the fixed post 20 realize the effective position under the action of the compression spring 5 limited.

[0030] In a further preferred solution of this embodiment, the sealing structure is an elastic cushion, and the elastic cushion has a rubber material whose elastic force is less than that of the compression spring 5. When th...

Embodiment 3

[0032] A construction method of a recyclable pipe hanging mold device includes the following steps:

[0033] S1. Paste double-sided tape on the side surfaces of the first assembly 1 and the second assembly 2 that are in contact with the concrete, and apply a release agent on the surface inside the double-sided tape;

[0034] S2. Install a positioning plate 3 suitable for the diameter of the embedded pipeline on the first assembly 1 and the second assembly 2, and after the sealing structure on the positioning plate 3 contacts the embedded pipeline, the first assembly 1 and the second assembly Assembly 2 The side with double-sided tape is bonded to the concrete;

[0035] S3. By matching the locking assembly with the corresponding positioning groove 7, rotating the clamping rod 10 drives the cam 18 to squeeze the groove 19 to drag the rod 9 and then drive the rotation of the gear 13 that meshes with the upper teeth of the rod 9 to make it lock The pawl 8 is connected with the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com