Pipeline fastener convenient to operate and method

A technology for fasteners and pipes, which is applied in the direction of pipe components, pipes/pipe joints/fittings, passing elements, etc., which can solve the problem of unreliable sealing of pipe fastening connections, reduce the safety of pipe fastening connections, and reduce the cost of pipe fasteners. Disassembly and assembly efficiency and other issues, to achieve the effect of good practicability, simplify the disassembly and assembly steps, and improve the disassembly and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the drawings:

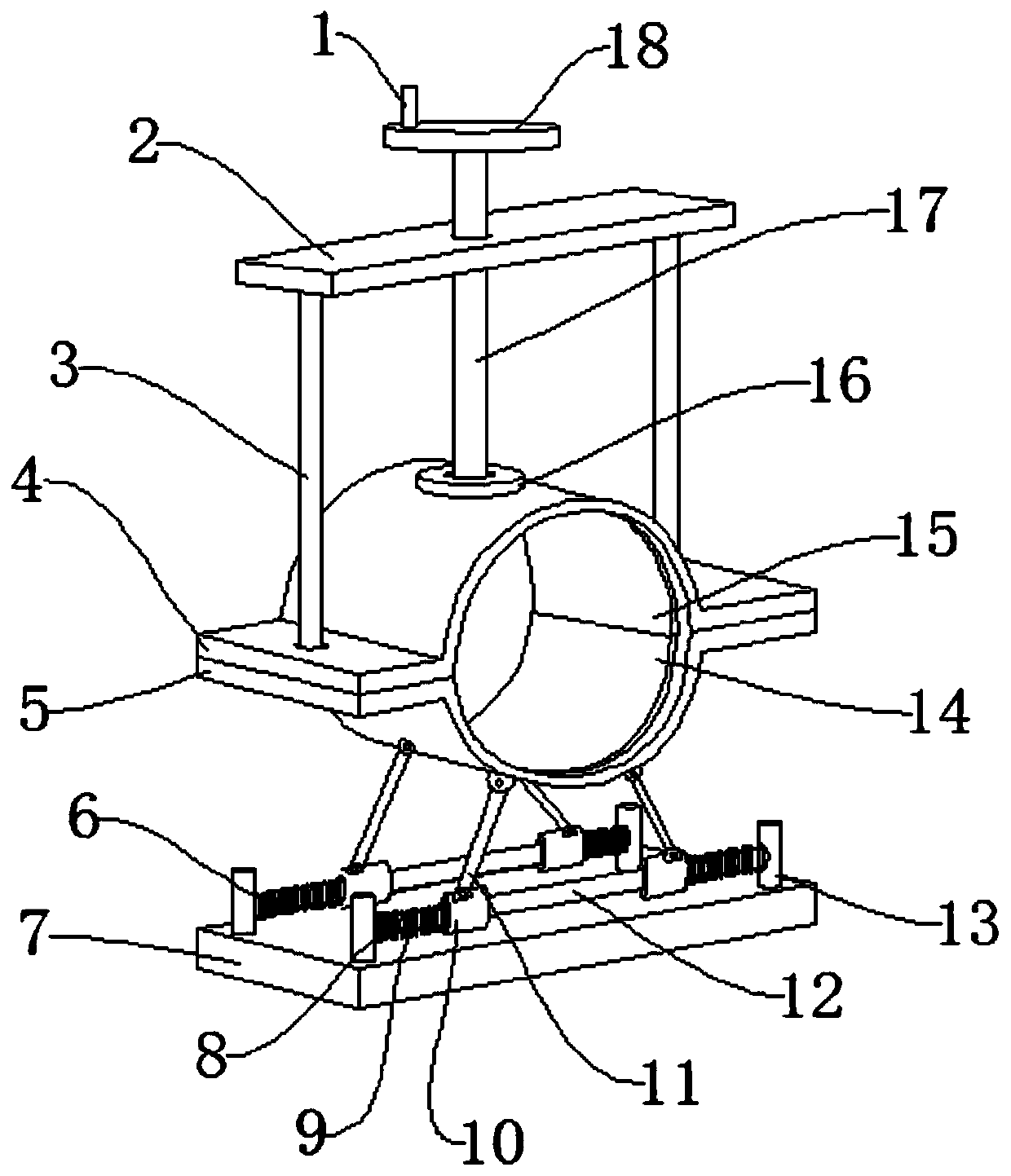

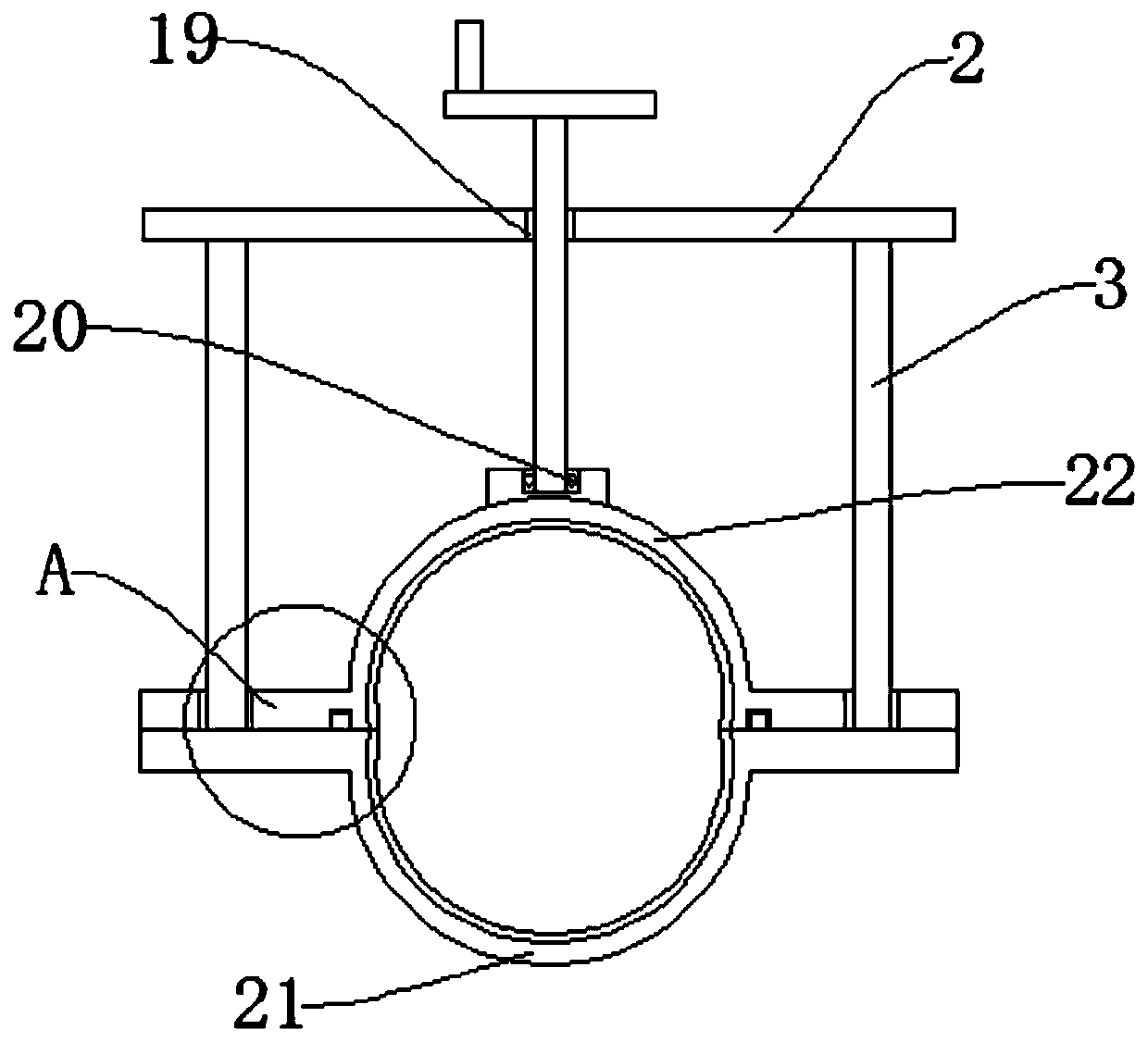

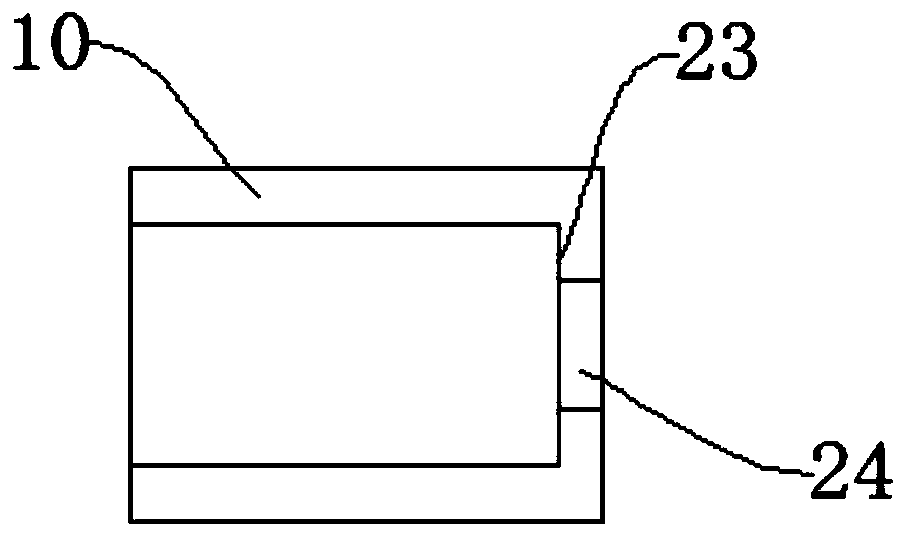

[0034] Such as Figure 1-Figure 4 As shown, an easy-to-operate pipe fastener includes a top cover 4, a bottom cover 5, and a turntable 18. The bottom cover 5 is provided below the top cover 4, and a clamping platform is formed in the middle of the top cover 4 One 22, the middle of the bottom cover 5 is formed with a clamping platform two 21, the upper end of the bottom cover 5 is welded with guide rods 3 on both sides, the top of the guide rod 3 is welded with a support plate 2, and the middle of the support plate 2 is formed There is a screw hole 19, a screw 17 is arranged in the screw hole 19, the top of the screw 17 is welded with the turntable 18, and the upper side of the turntable 18 is connected with a rotating handle 1 by screws, and the top cover 4 is close to The guide rod 3 is formed with a guide hole 26, the upper middle of the top cover 4 is welded with a mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com