Combined structure for observing fire

A combined structure and positioning groove technology, applied in the direction of burners, combustion methods, and combustion types that utilize capillary action, can solve problems such as user inconvenience, overheating of containers and fuel, etc., to block heat transfer and improve use safety , Reduce the effect of heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

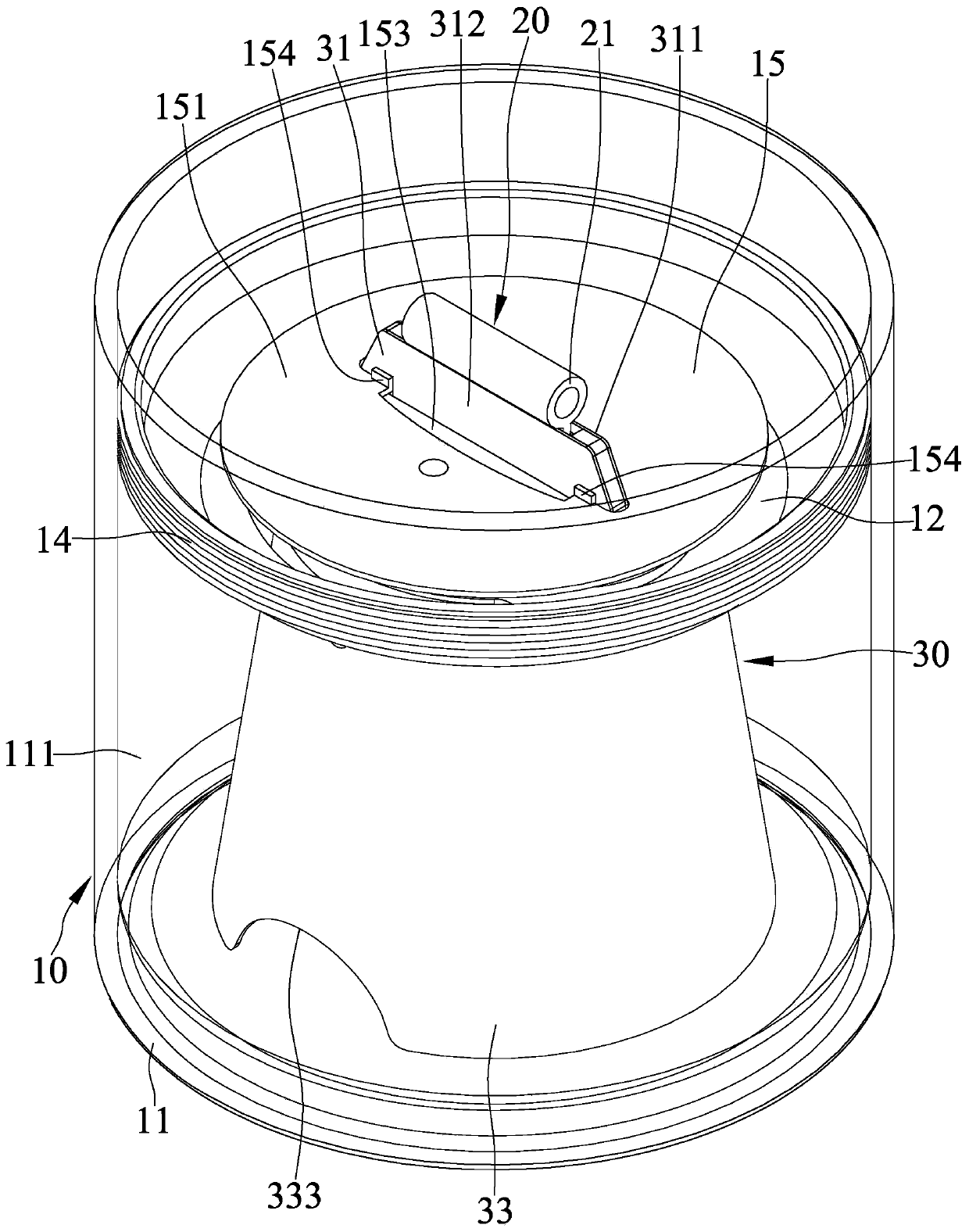

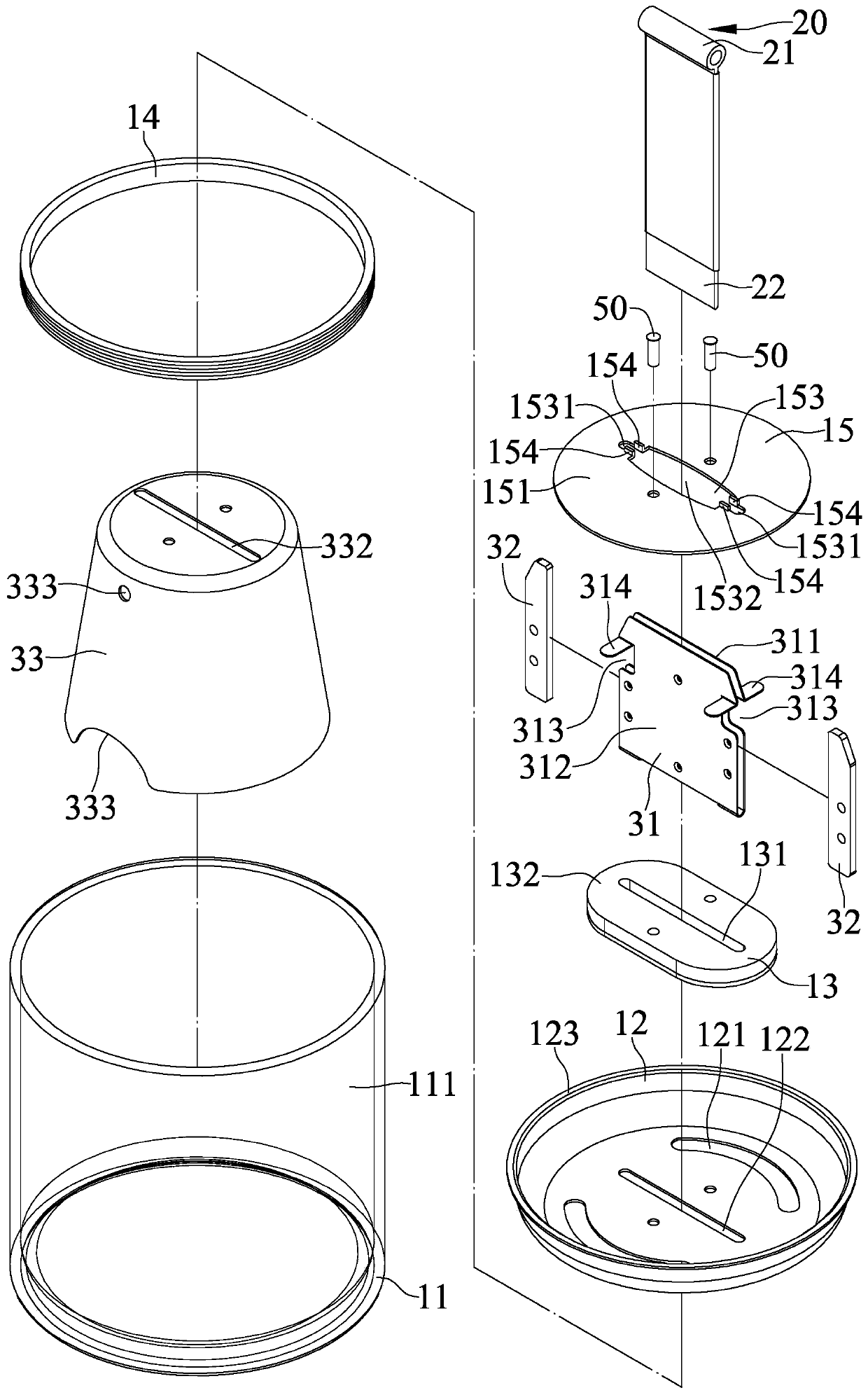

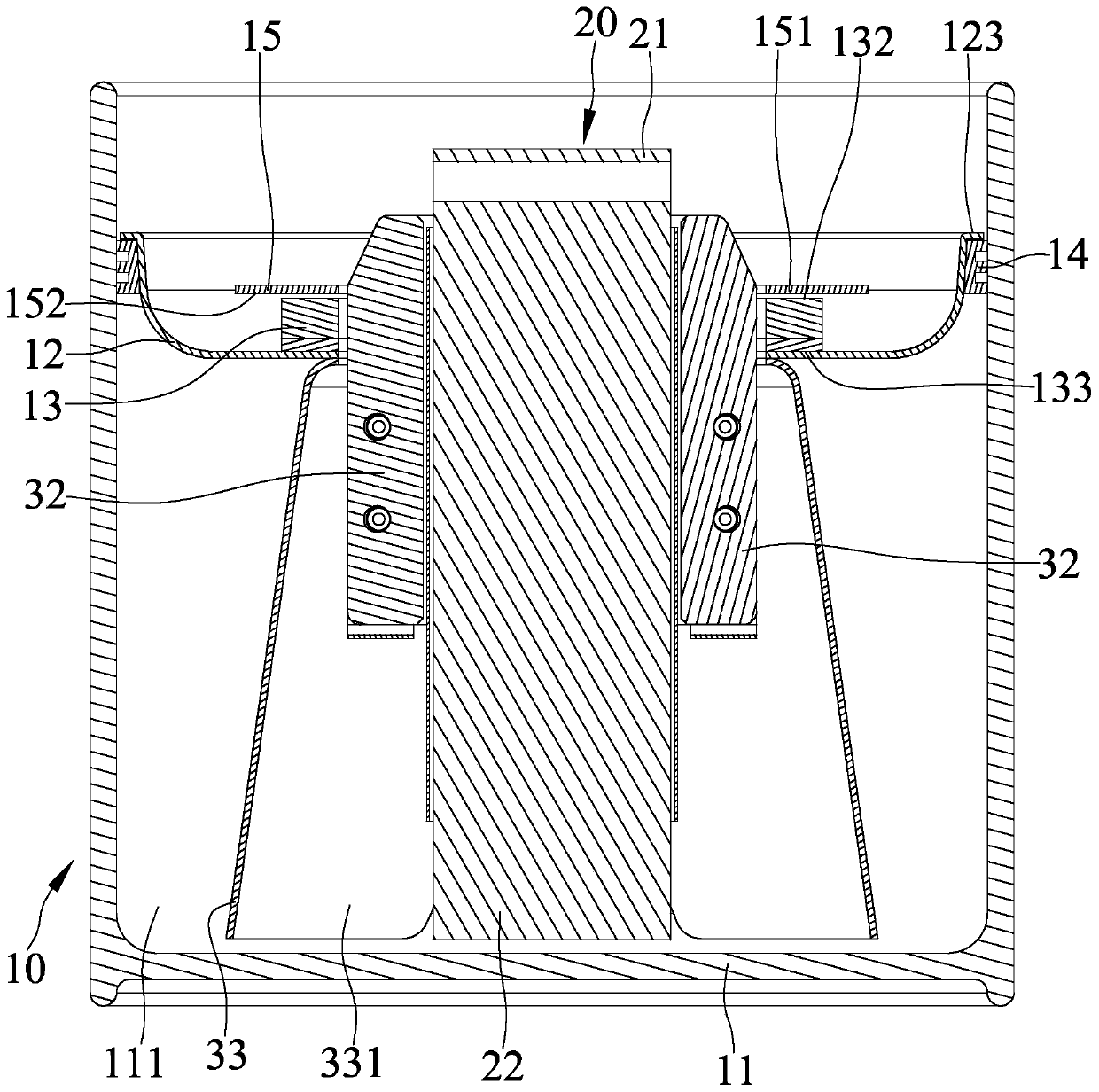

[0027] Please refer to Figure 1 to Figure 4Shown is the appearance view, exploded view and sectional view of the combined structure of the ornamental fire of the present invention. The combined structure of the ornamental fire of the present invention includes a containing device 10 , a burning device 20 and a fixing device 30 . The accommodating device 10 includes a fuel container 11 , a top cover 12 , a heat insulator 13 , a leak-proof heat insulator 14 and a shield 15 . The fuel container 11 is made of transparent material. The fuel container 11 includes an accommodating portion 111, the accommodating portion 111 is arranged in the fuel container 11, the top cover 12 is connected with the accommodating portion 111 of the fuel container 11, the top cover 12 has a filling hole 121 and A first positioning groove 122, the filling hole 121 and the first positioning groove 122 are provided through the top cover 12 and communicate with the accommodating portion 111, the heat ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com