Cut tobacco drying process moisture prediction control method and system based on recurrent neural network

A technology of recursive neural network and predictive control, applied in general control system, control/regulation system, adaptive control, etc., can solve problems such as poor stability of outlet moisture content and increase outlet moisture content stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

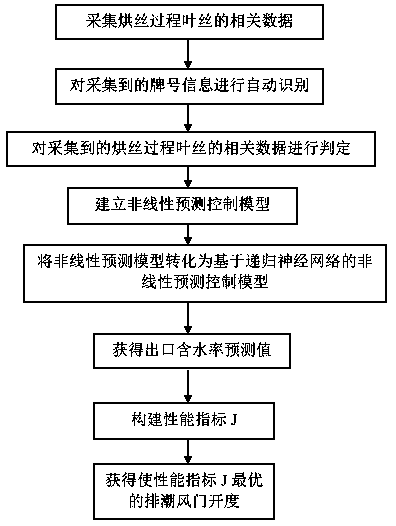

[0055] Embodiment 1, a method for predicting and controlling moisture in the silk drying process based on a recursive neural network, such as figure 1 shown, including:

[0056] A) Collect the relevant data of shredded leaves during the drying process. The relevant data include brand information, inlet moisture content, process hot air temperature, target outlet moisture content, moisture exhaust damper opening, steam pressure and incoming material mass flow rate.

[0057] B) Automatically identify the collected grade information, and obtain the control parameters of the corresponding batch of shredded leaves, the control parameters include the target outlet moisture content and the opening range of the damp discharge damper;

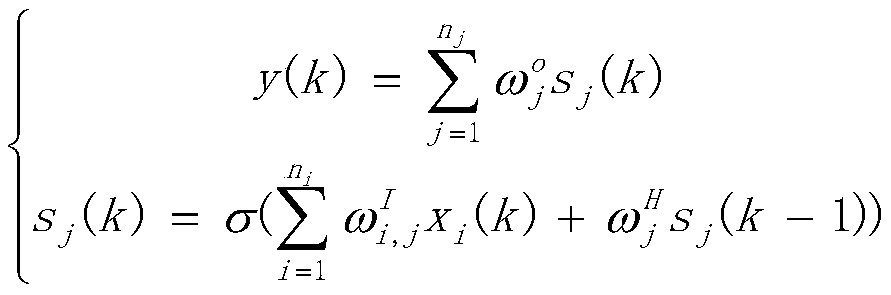

[0058] C) Judgment is made on the collected relevant data of shredded leaves in the drying process, and the normal working range of each relevant data is set. When the relevant data are all within the normal working range, a nonlinear predictive control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com