Moisture control method and system in rehumidification and humidification process based on multiple regression

A technology of multiple regression and multiple regression model, applied in the manufacture of computing systems, tobacco preparation, instruments, etc., can solve the problems of affecting the stability of the outlet moisture content, unable to adjust the amount of water added, affecting the stability of the outlet moisture content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

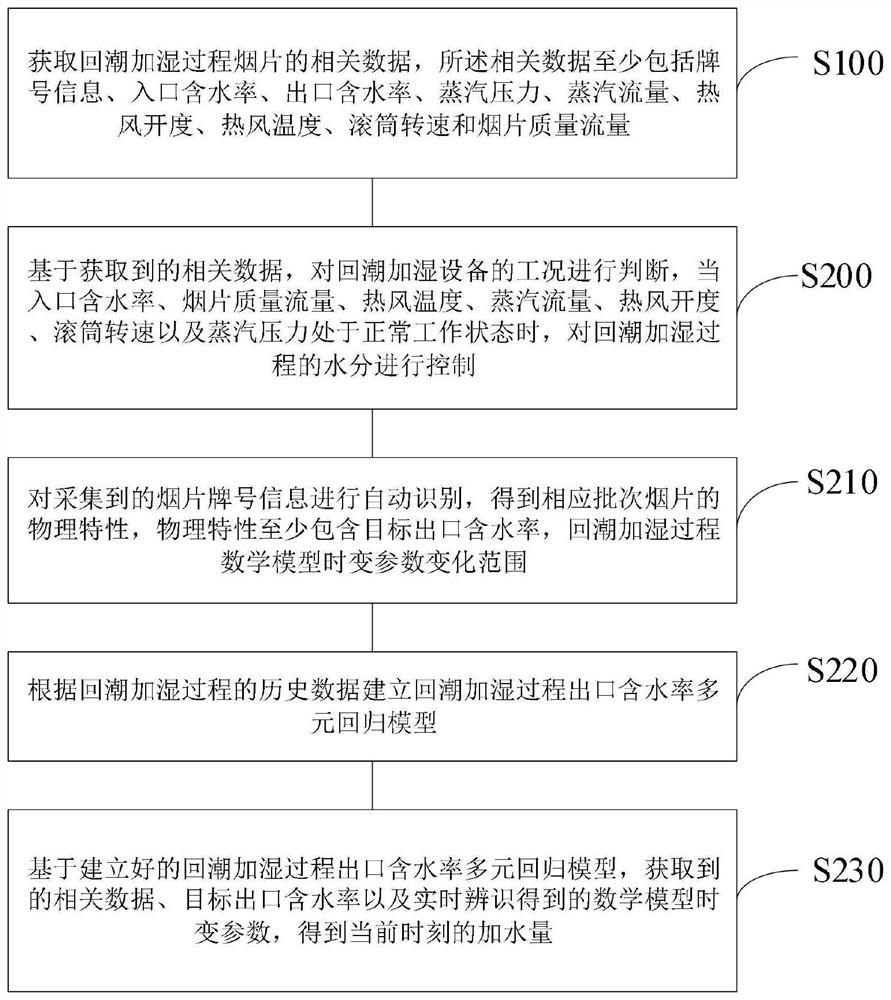

Method used

Image

Examples

Embodiment 2

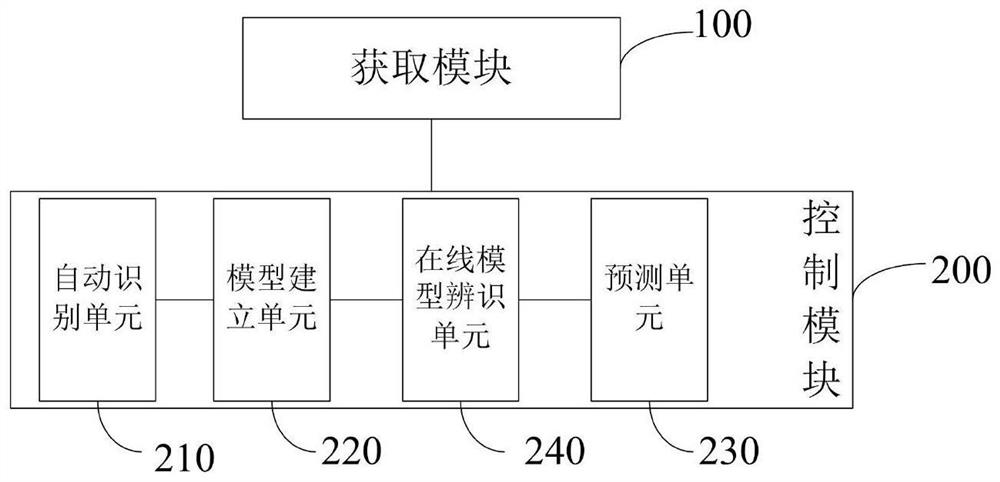

[0080] A moisture control system in the humidification process based on multiple regression, such as figure 2 As shown, it includes an acquisition module 100 and a control module 200; the control module 200 includes an automatic identification unit 210, a model building unit 220 and a prediction unit 230;

[0081] The acquiring module 100 is used to acquire the related data of the tobacco sheet in the humidifying process, the related data at least includes brand information, inlet moisture content, outlet moisture content, target outlet moisture content, steam pressure, steam flow, hot air opening, Hot air temperature, drum speed and smoke sheet mass flow rate;

[0082] The control module 200 is used to judge the working condition of the humidification equipment based on the obtained relevant data, when the inlet moisture content, the mass flow rate of the cigarette sheet, the temperature of the hot air, the flow rate of the steam, the opening degree of the hot air, the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com