Garbage compression device for garbage salvage ship

A technology for garbage compression and salvage ships, which is used in presses, transportation and packaging, special-purpose ships, etc., can solve the problems of fragile devices, poor compression effect, and low compression efficiency, and achieves convenient subsequent crushing and continuous work. , The effect of preventing adhesion of garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

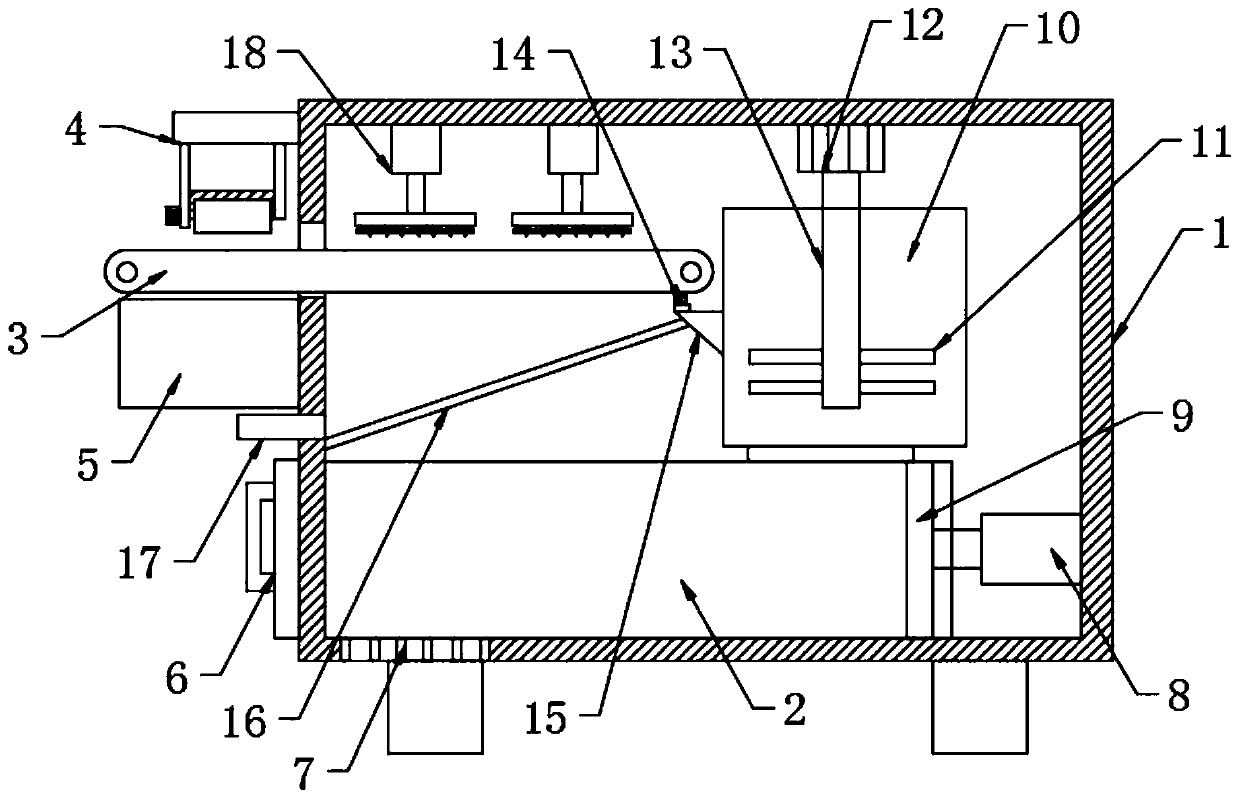

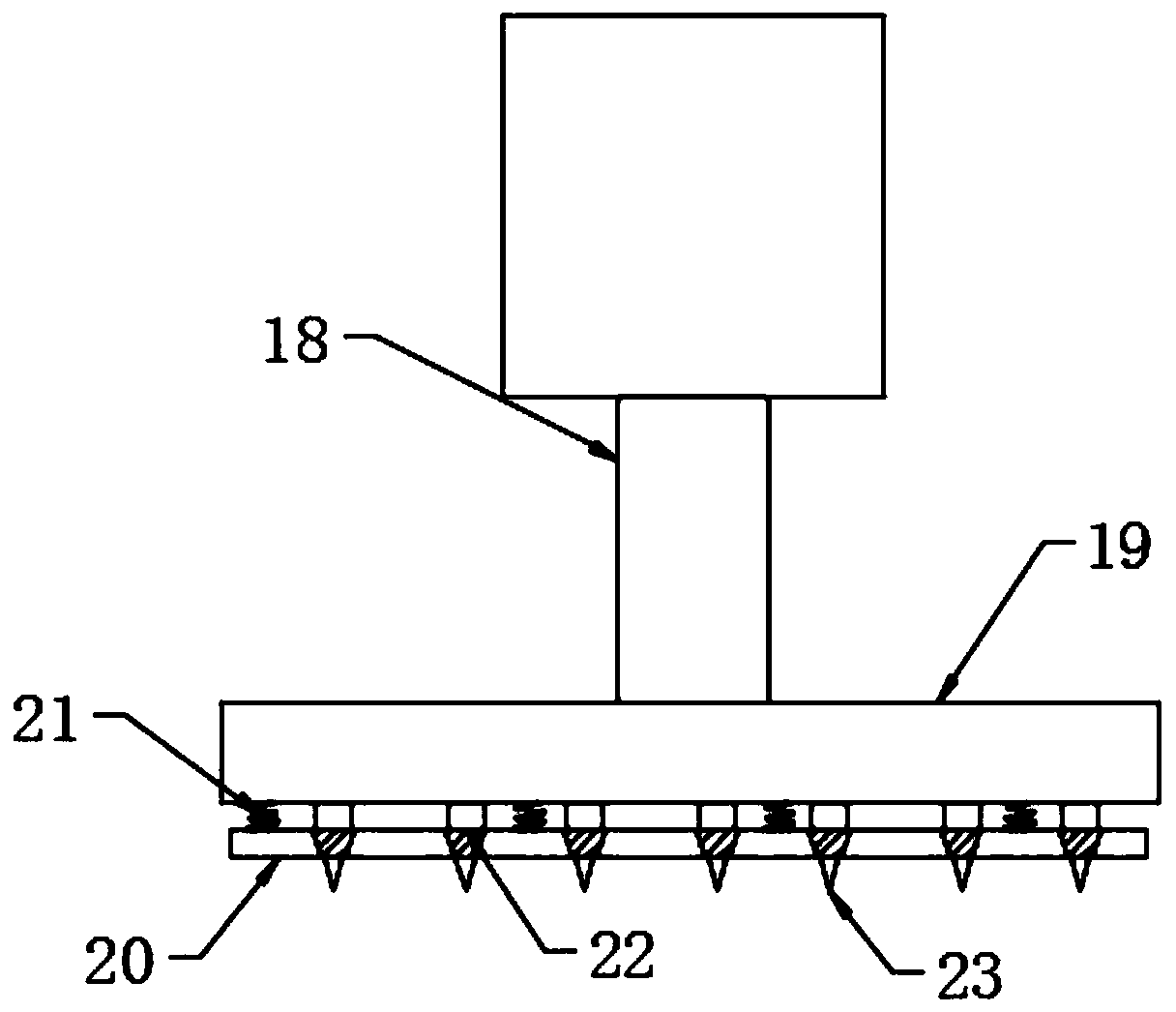

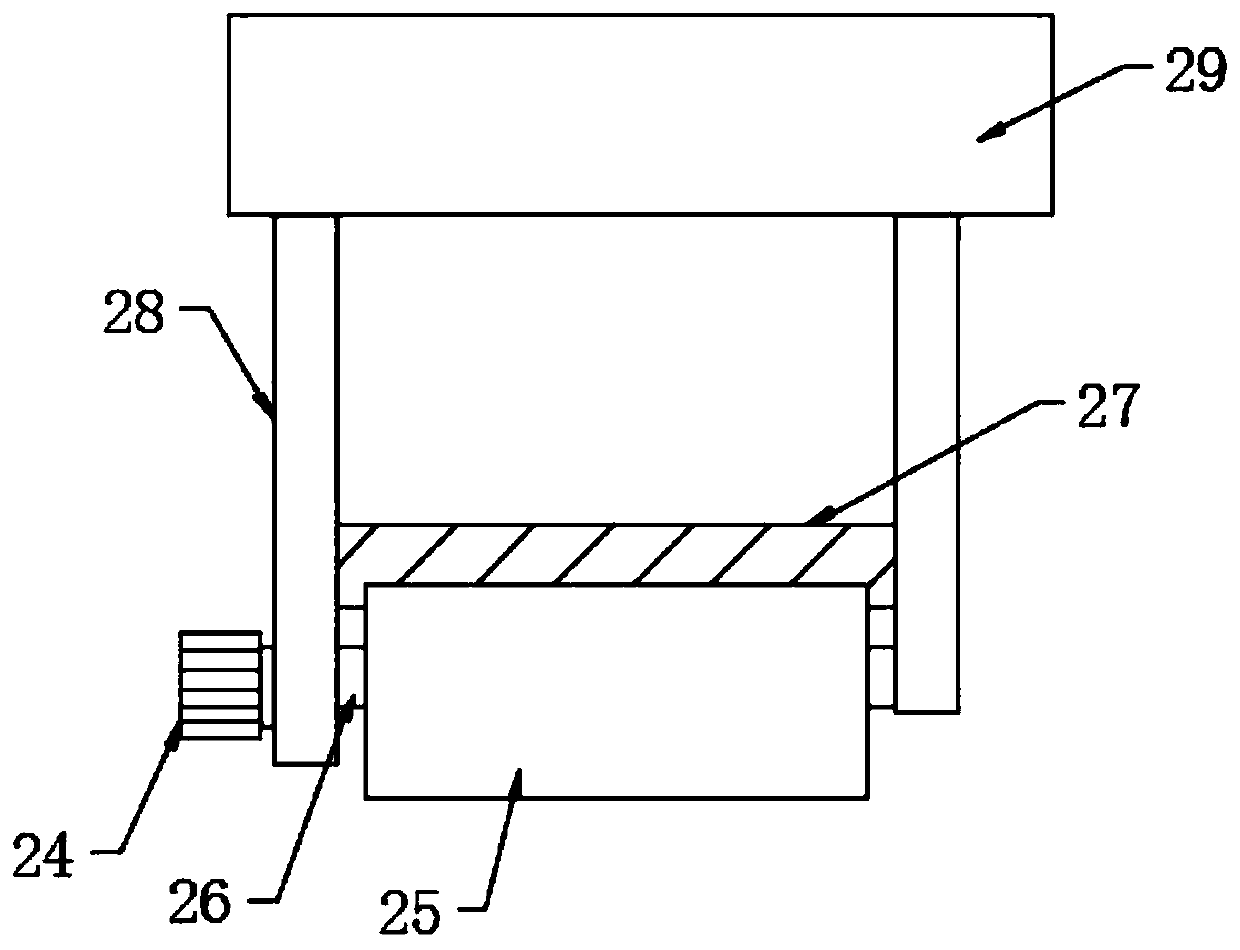

[0026] Such as Figure 1-4 As shown, the present invention provides a technical solution: a garbage compression device for salvage ships, including a treatment box 1, a conveying mechanism 3, an iron-absorbing mechanism 4, a crushing mechanism, a crushing mechanism and a compression mechanism, and the conveying mechanism 3 is located at One side of the outside of the treatment box 1, and one end of the conveying mechanism 3 extends inside the treatment box 1, the iron-absorbing mechanism 4 is located on the outside side of the treatment box 1, and the iron-absorbing mechanism 4 is located above the conveying mechanism 3, and the crushing mechanism is located The top inside of the processing box 1, and the crushing mechanism is located directly above the conveying mechanism 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com