SMA-spring-driven flywheel repeatable locking mechanism

A spring-driven, repetitive locking technology, applied in the direction of aerospace aircraft, aircraft, motor vehicles, etc., can solve the problems of poor synchronization, SMA-spring locking release mechanism cannot be automatically reset, etc., achieve high synchronization, improve unlocking Reliability, the effect of releasing a large load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

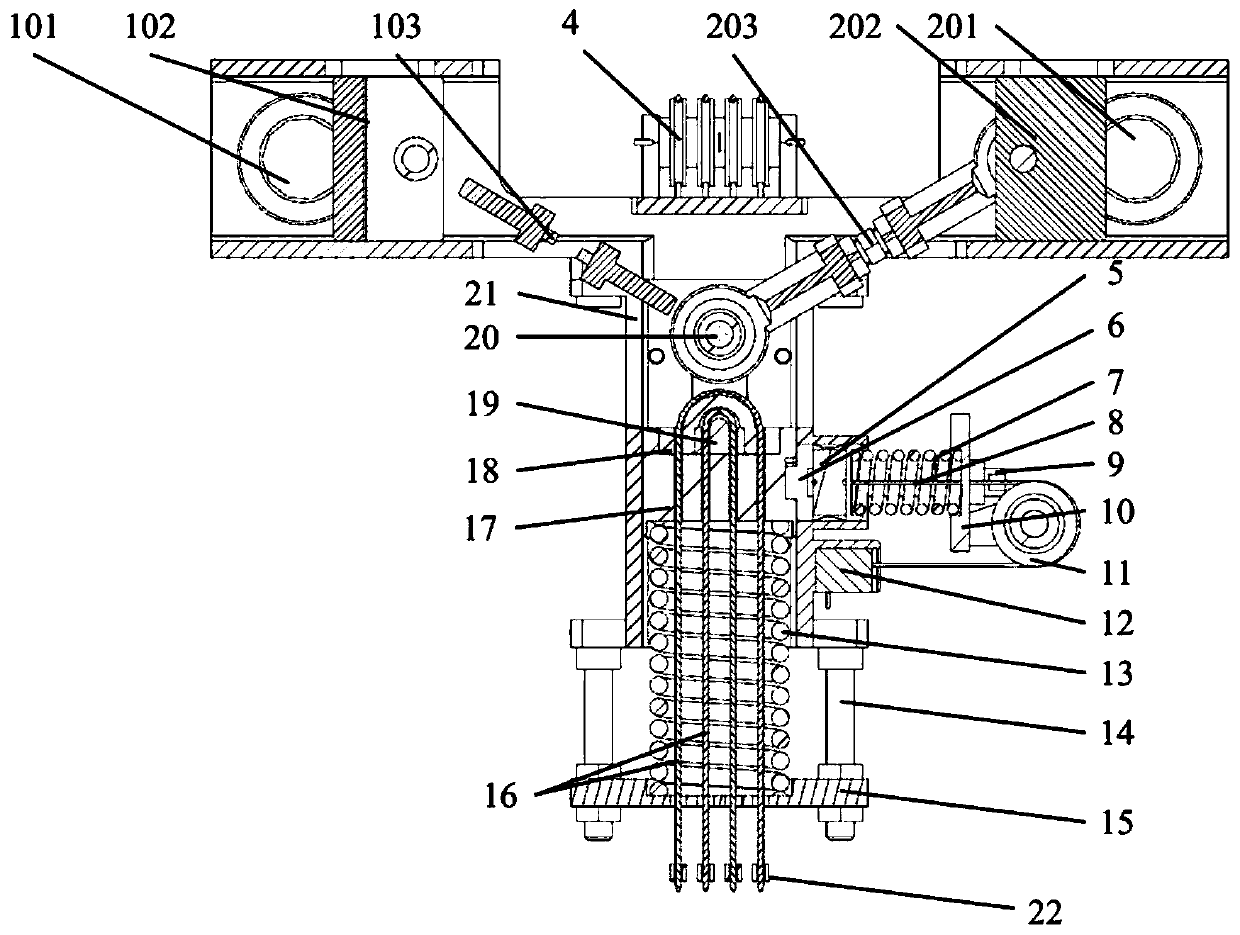

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

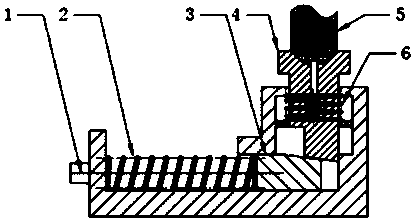

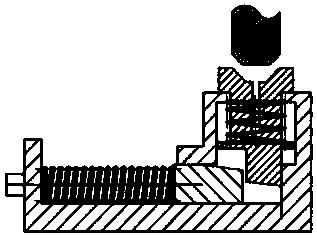

[0042] The present invention provides a SMA-spring-driven flywheel repeatable locking mechanism, the structure of which is as follows: figure 2 and image 3 As shown, it includes: left lock cylinder 101, left wedge 102, left connecting rod 103, right lock cylinder 201, right wedge 202, right connecting rod 203, housing pulley 4, limit block inner pulley 5, limit Block 6, keep unlocking spring 7, trigger and lock SMA wire 8, screw 1 9, keep unlocking spring end cover 10, keep unlocking spring end cover pulley 11, trigger and lock SMA wire insulating block 12, top tightening spring 13, screw 2 14. Tightening spring end cover 15, unlocking SMA wire 16, slider 17, large pulley inside slider 18, small pulley inside slider 19, slider shaft 20, housing 21, housing pulley 2 22, unlocking SMA wire Insulation block 23.

[0043] Wherein, the tensioning spring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com