Method for dynamic repairing of metal electrodes in IPMC driving process

A dynamic repair, metal electrode technology, applied in the direction of measuring electricity, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of IPMC displacement and output force, electrode layer cracks, poor reusability, etc., to improve output performance, overcoming resistance reduction, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Fabrication of IPMC with the ability to dynamically repair electrodes

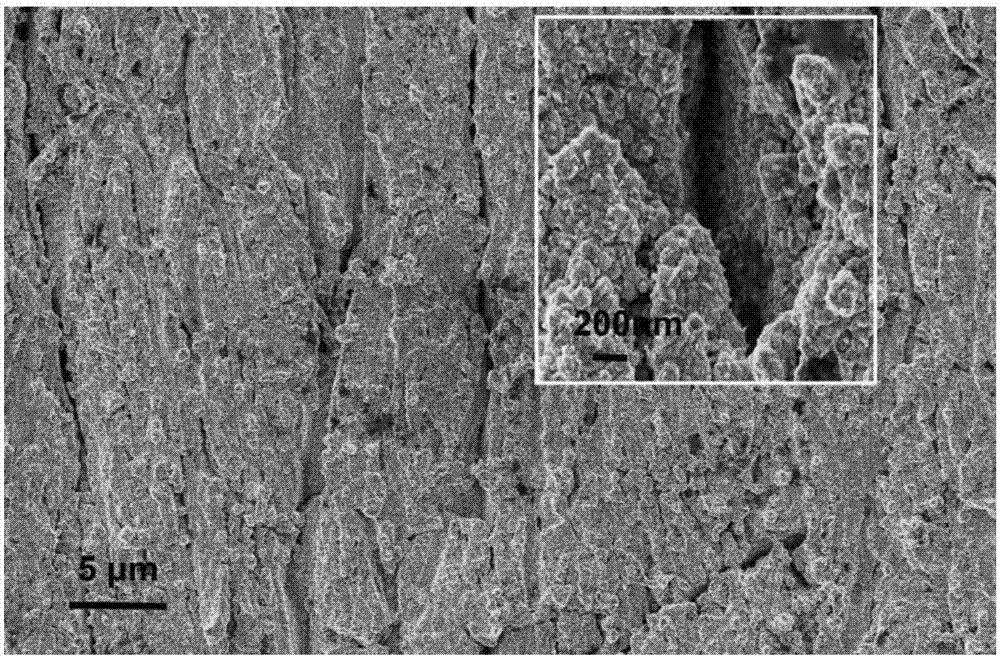

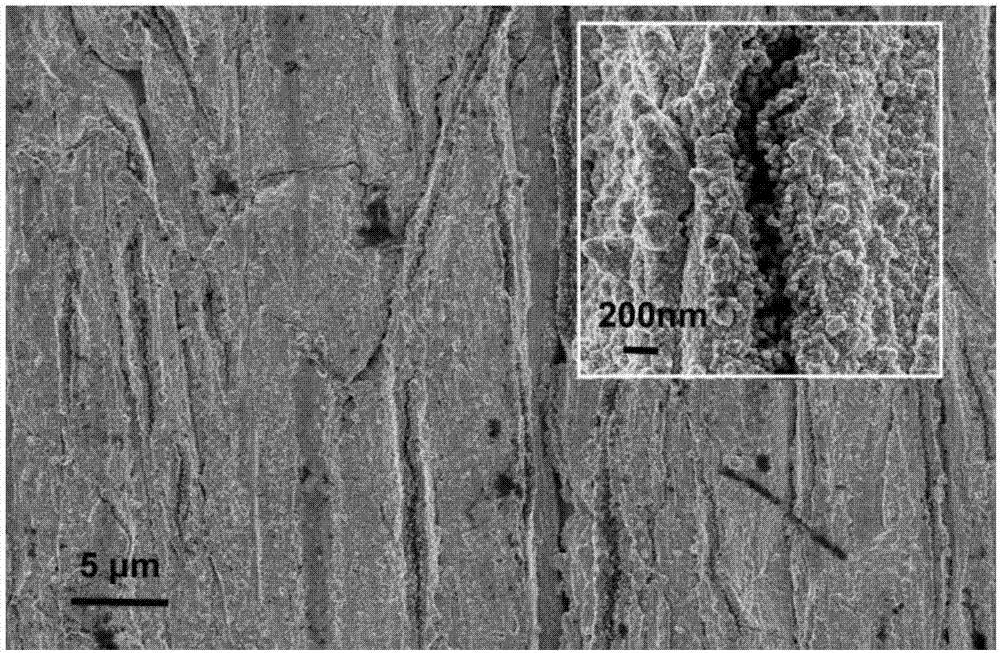

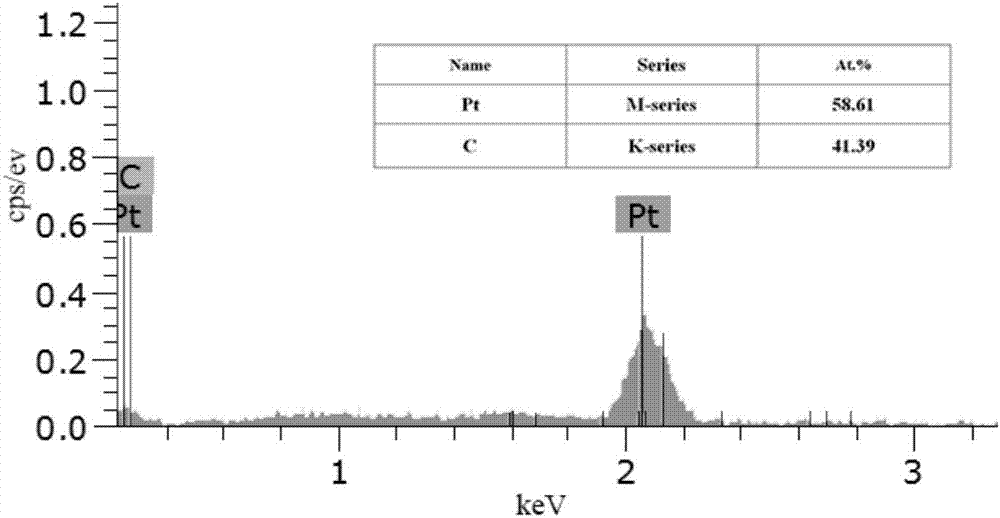

[0038] The commercial Nafion membrane produced by DuPont Company of the United States is used as the ion exchange layer, platinum is used as the electrode of IPMC, and a platinum electrode metal layer is deposited on the surface of the Nafion membrane by two electroless plating methods. The preparation process of IPMC is as follows: ① Surface roughening of the film: the roughening process is to increase the contact area between the electrode and the base film to facilitate the deposition of Pt particles. First, cut the Nafion base film of appropriate size, and with the addition of abrasives, polish the front and back sides for 15 minutes by manual grinding method; ②Membrane cleaning: The purpose is to remove impurities such as abrasives on the surface of the base film The basement membrane was ultrasonically cleaned for 30 minutes, boiled with 5% hydrochloric acid for 30 minutes, and then deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com