Dynamically-combined helical driving device

A screw transmission and dynamic technology, which is applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of screw stress deterioration, high cost, and heavy screws, etc., and achieve small installation space and strong practicability , the effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

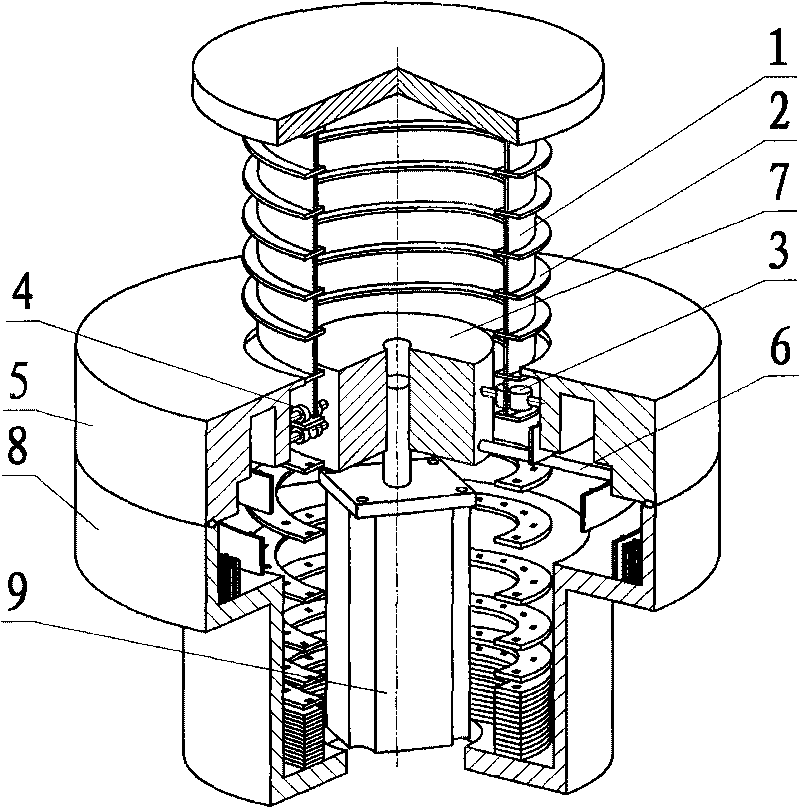

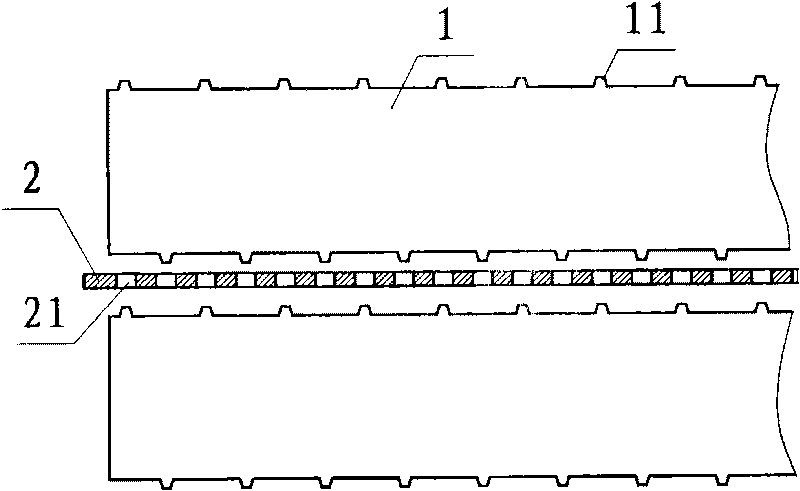

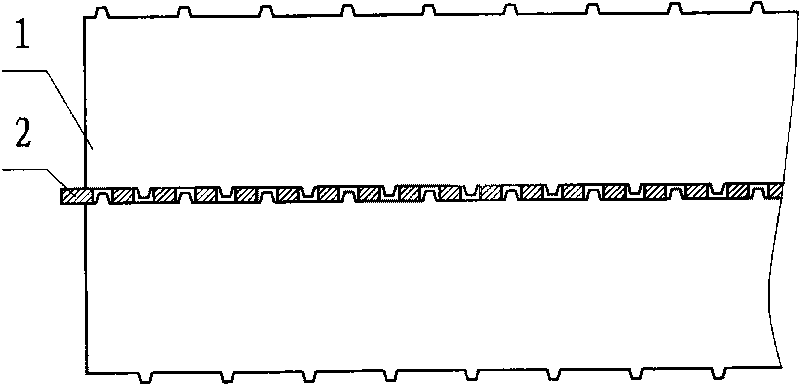

[0029] See attached figure 1 , This embodiment of the dynamic combined screw transmission device of the present invention has an outer diameter of the combined screw of 300 mm and a stroke of 5000 mm. The supporting helix 1 and the connecting helix 2 are produced by cold working of a stainless steel plate with a cross-sectional size of 30mm×3mm. The support 8 is made of aluminum alloy, in the shape of an inverted tube cap, and the diameter of the outer ring is 450mm. The motor 9 adopts a DC motor with a power of 1500 watts, the coaxial sleeve is placed in the support 8, and the output shaft is upward. The output shaft is coaxially fitted with an engaging inner core 7, and the engaging inner core 7, the engaging outer core 5 and the connecting rod 6 are all made of stainless steel. The supporting helical guide wheel 3 and the connecting helical guide wheel 4 are wear-resistant and noise-reducing commercially available nylon wheels with a diameter of 20mm and a width of 20mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com