Filter element structure capable of storing pure water and foam film water purification system applying filter element structure

A filter element and water purification technology, which is used in water/sewage treatment, fixed filter element filters, and multi-stage water/sewage treatment. It can solve the problems of high TDS value and water quality that does not meet the filtration requirements, and reduce the TDS value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

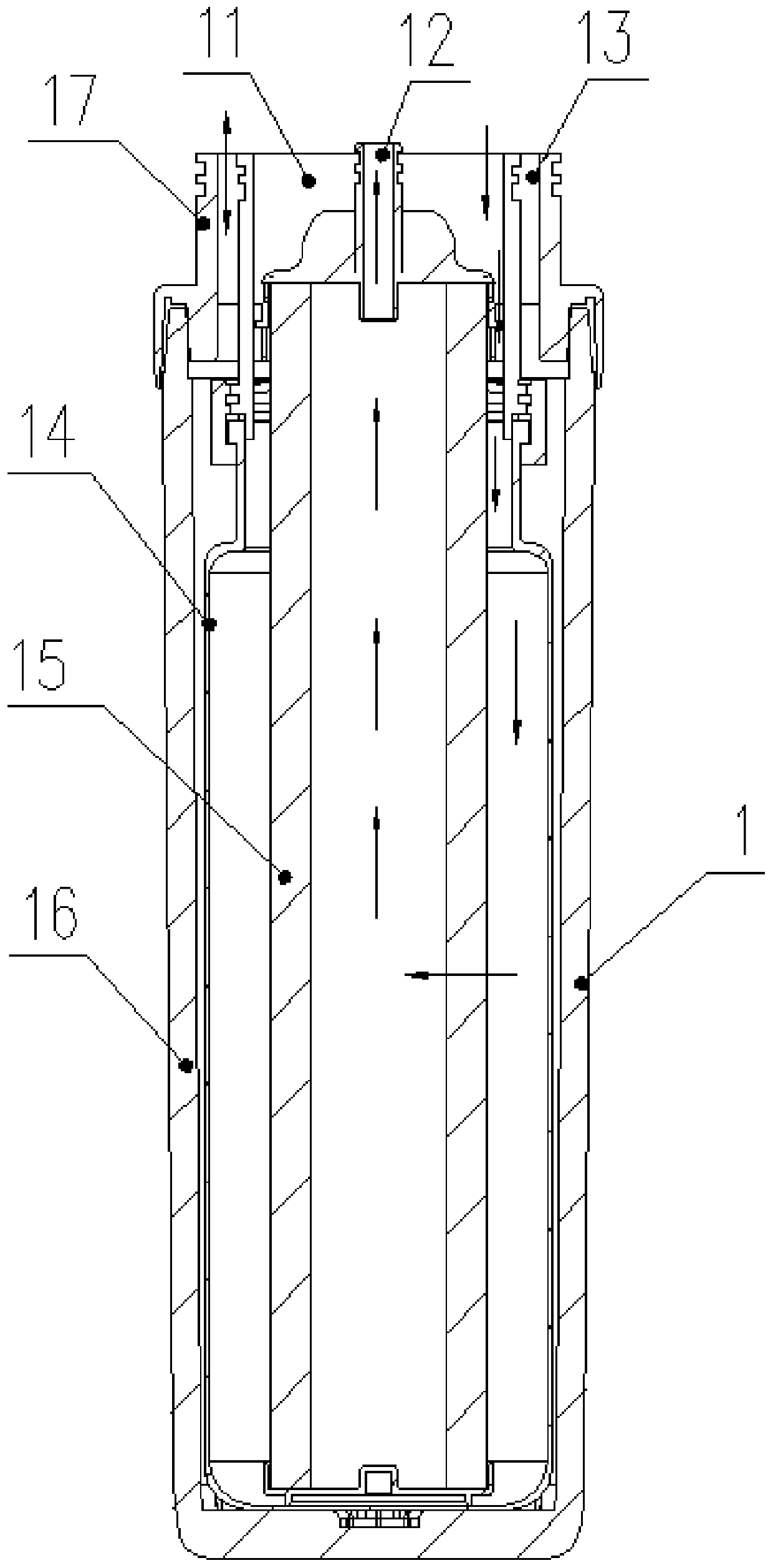

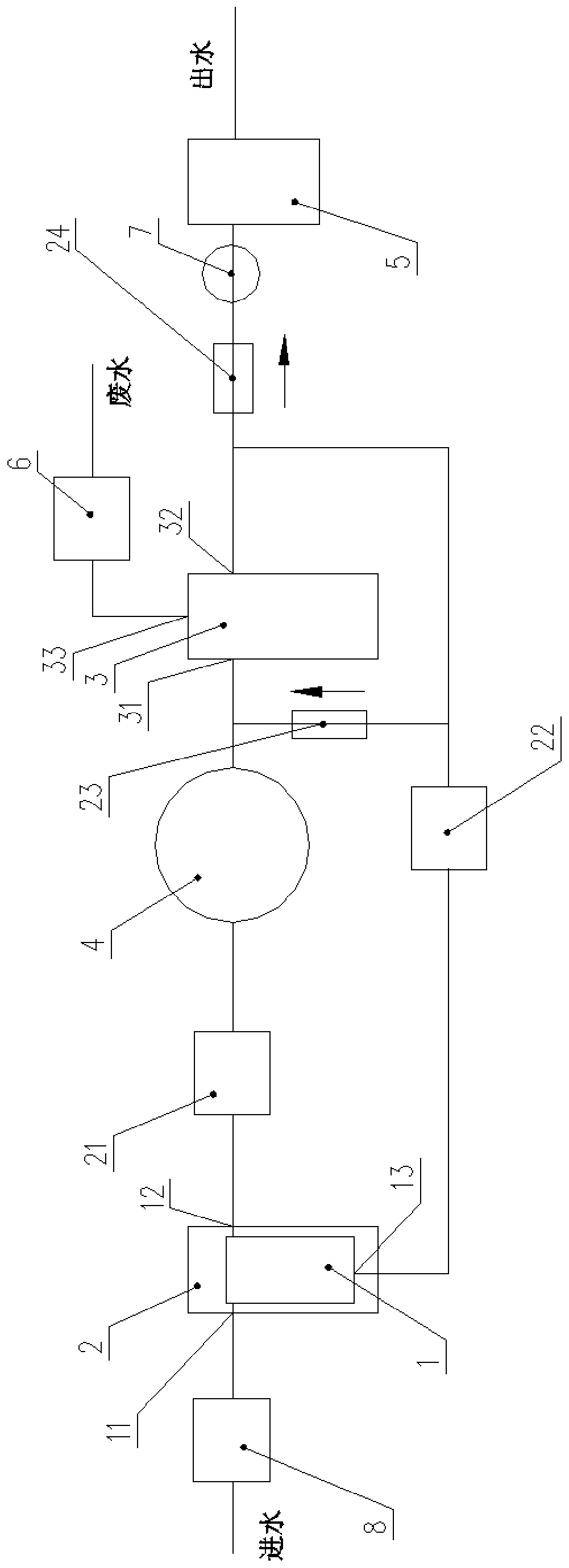

[0034] This embodiment discloses a pre-bubble film water purification system, which includes a pre-filter part 2, a reverse osmosis filter part 3, a post-filter part 5, a first pre-control valve 21, and a second pre-control valve 22 . The first pre-check valve 23 and the pressurization assembly 4, the pre-filter part 2 is applied as the above-mentioned filter element structure capable of storing pure water.

[0035] The reverse osmosis filter part 3 includes a clean water inlet 31, a pure water outlet 32 and a concentrated water outlet 33; The flow between the inlets 31 forms a clean water filtering flow channel; the water flow flows between the pure water outlet 32, the second pre-control valve 22 and the water storage inlet and outlet 13, forming a pure water storage flow channel; the water flow along the The flow between the water storage inlet and outlet 13, the second pre-control valve 22, the first pre-check valve 23 and the clean water inlet 31 forms a pure water bubb...

Embodiment 2

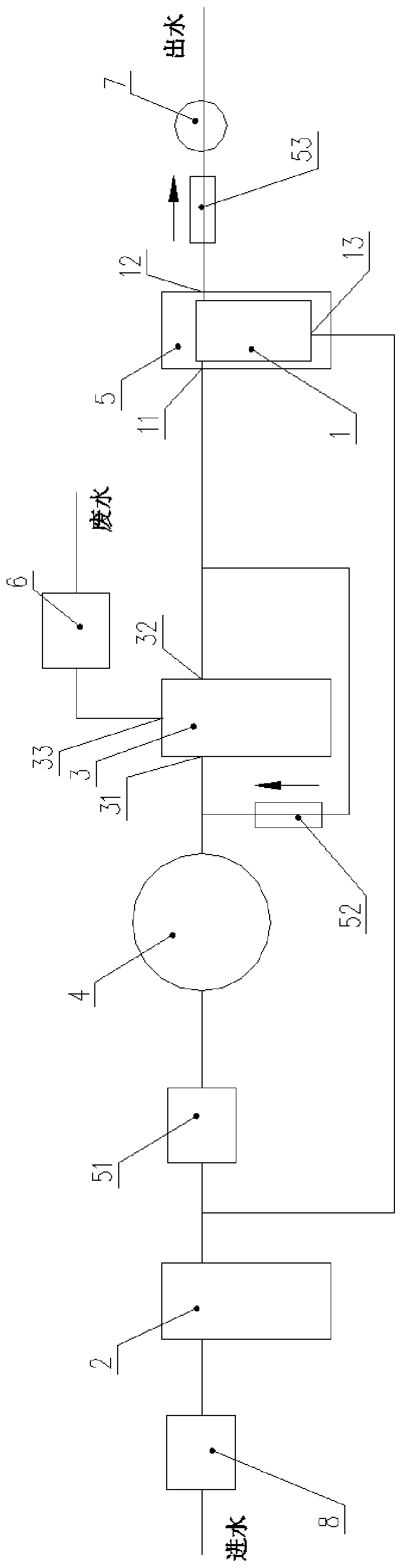

[0045] This embodiment discloses a post-installed bubble film water purification system, which is different from the above-mentioned embodiment 1 in that the filter element structure capable of storing pure water is applied to its post-installed filter part 5, and its waterway is adjusted accordingly .

[0046] Specifically, the post-foam water purification system includes a pre-filter 2, a reverse osmosis filter 3, a post-filter 5, a first post-control valve 51, a first post-check valve 52 and a pressurized Component 4, the post-filtering part 5 is applied with the above-mentioned filter element structure that can store pure water; the pre-filtering part 2 includes a clean water outlet, and the reverse osmosis filter part 3 includes a clean water inlet 31, a pure water Water outlet 32 and concentrated water outlet 33; the water flow flows between the clean water outlet and the water storage inlet and outlet 13, forming a water storage squeeze flow channel, and the water flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com