Open mask sheet for thin film deposition and method for manufacturing thereof

A manufacturing method and process technology, which is applied in the field of open mask sheet for thin film process and its manufacturing, can solve the problems such as the reduction of display edge precision, and achieve the effect of improving edge precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

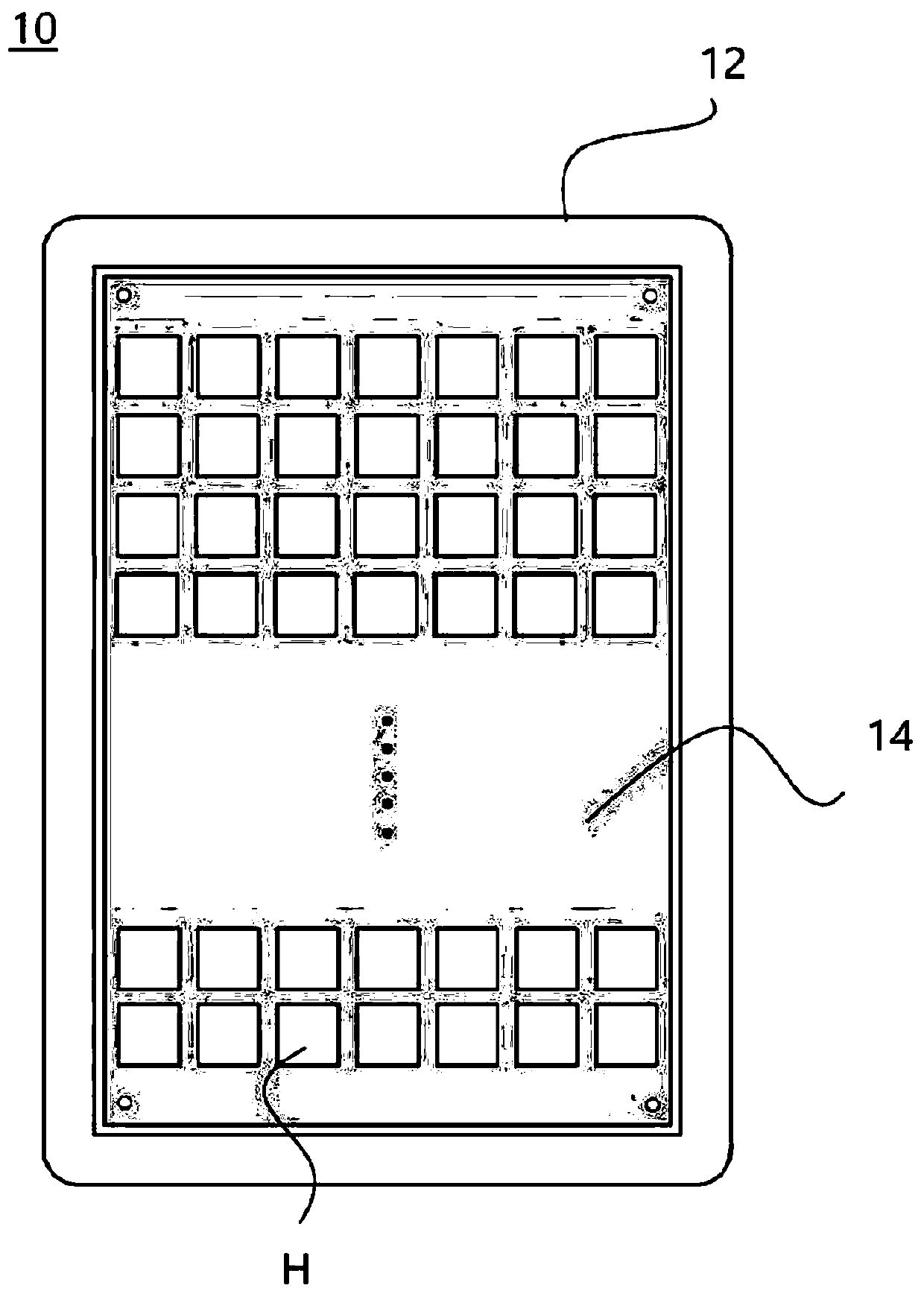

Image

Examples

Embodiment Construction

[0041] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. For reference, the following descriptions and drawings are merely illustrations to facilitate understanding of the present invention, and do not limit the technical scope of the invention. In other words, the embodiments described below can undergo various modifications during on-site implementation. If these modifications are within the technical idea of the present invention, they belong to the present invention, and those of ordinary skill in the art to which the present invention belongs can easily understand through the following descriptions Technical thought of the present invention.

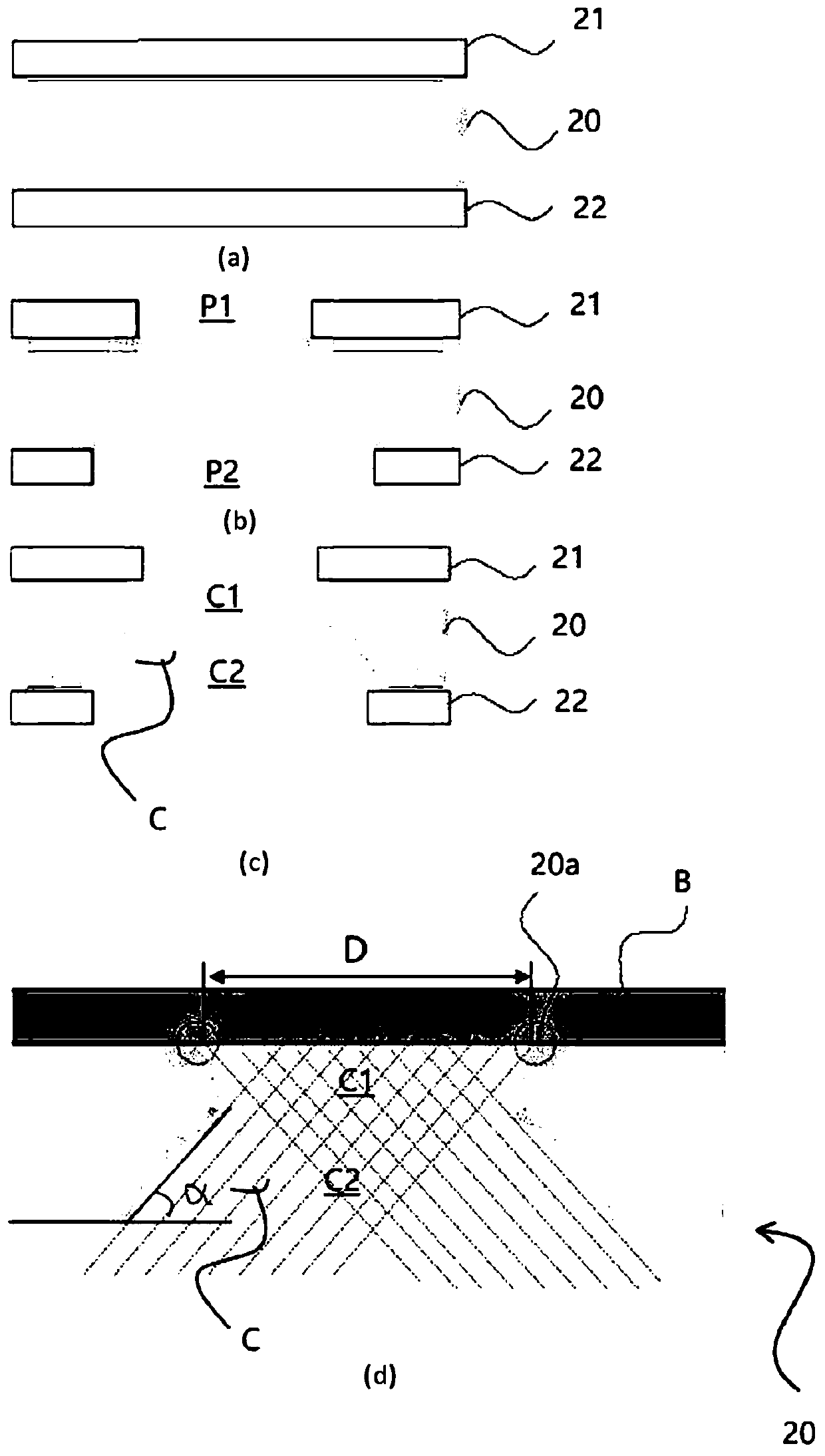

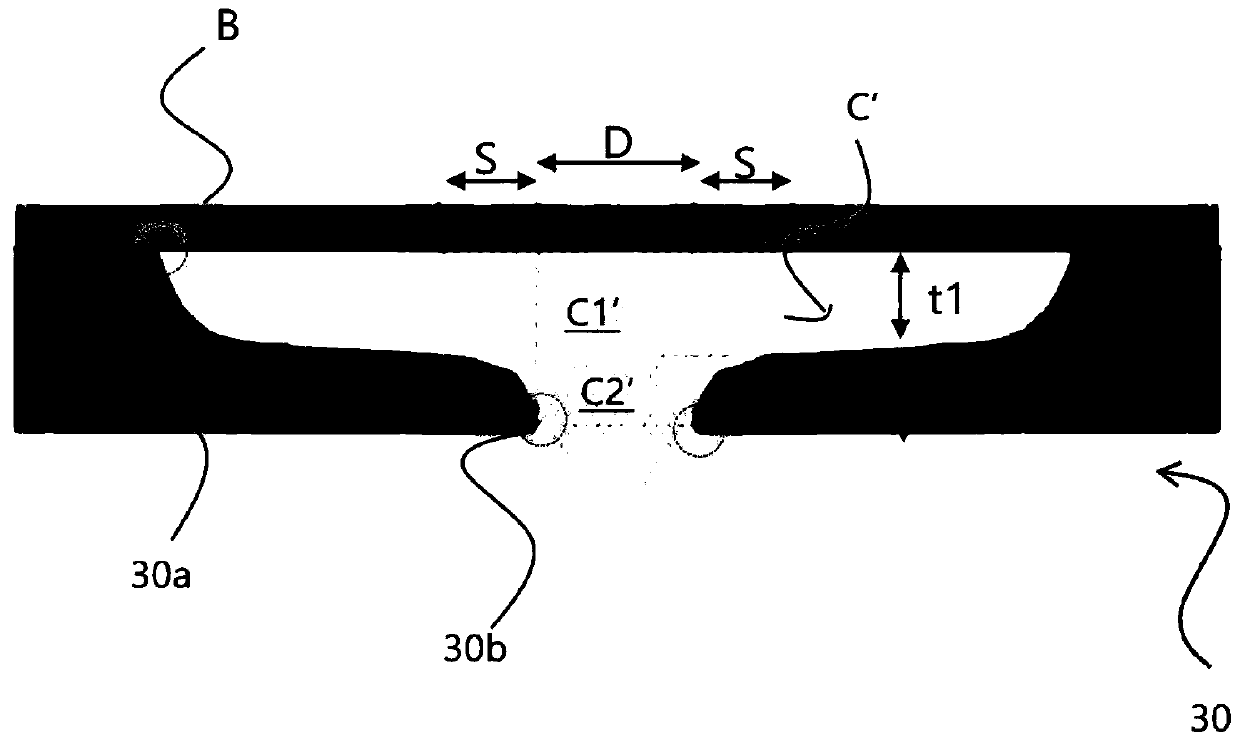

[0042] Figure 4 It is a schematic cross-sectional view showing the opening structure of the open mask sheet according to the embodiment of the present invention.

[0043] refer to Figure 4 , shows a state where the opening e of the open mask sheet for thin film proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com