A basement communication opening structure based on waterproof steel plate

A technology of water-stop steel plate and connecting port is applied in the field of anti-leakage, which can solve the problems of tearing, easy aging, and the effect is not very good, and achieve the effect of preventing groundwater leakage and prolonging the infiltration path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

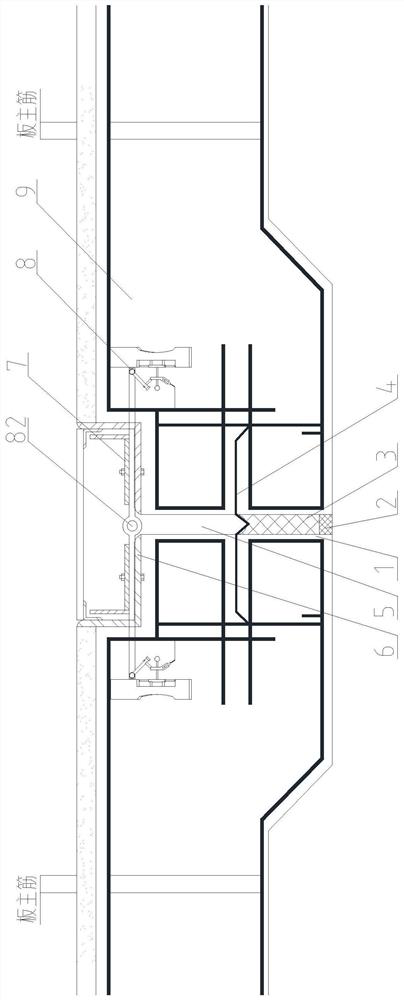

[0033]Seefigure 1 ,image 3 ,Figure 4 withFigure 5 The present invention provides its technical solution, one based on the basement interconnector structure based on the soil steel sheet, including GB flexible filler 2 at the bottom of the crack 1, is provided at top of GB flexible filler 2, polyethylene plastic arranged to mesh The waterproof bar 3 is located in the crack 1, and the V-shaped water plate 4 is disposed at the top of the polyethylene plastic waterproof bar 3, which is filled in the crack 1 of the V-shaped soil steel plate 4, and the crack 1 The opening covering a layer of water expansion stopper rubber strip 6, each of the two sides of the water rubber strip 6 is disposed, and the angle steel 7 is connected to the water expansion stopper rubber strip 6 by the reinforcing structure 8 and is fixed. Wall 9.

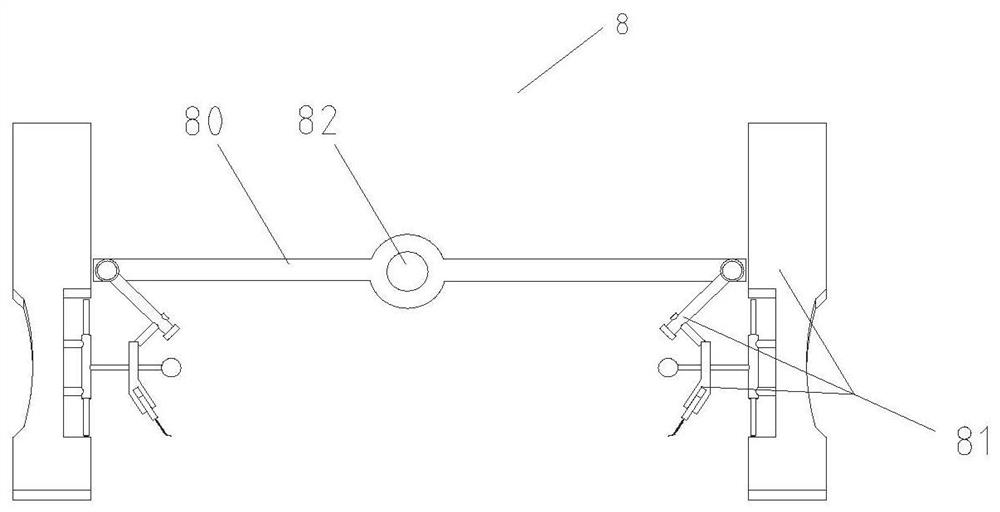

[0034]Specifically, the reinforcing structure 8 includes two traveling rods 80, respectively, respectively, an elastic fastening assembly 81, respectively, coupled betw...

Embodiment 2

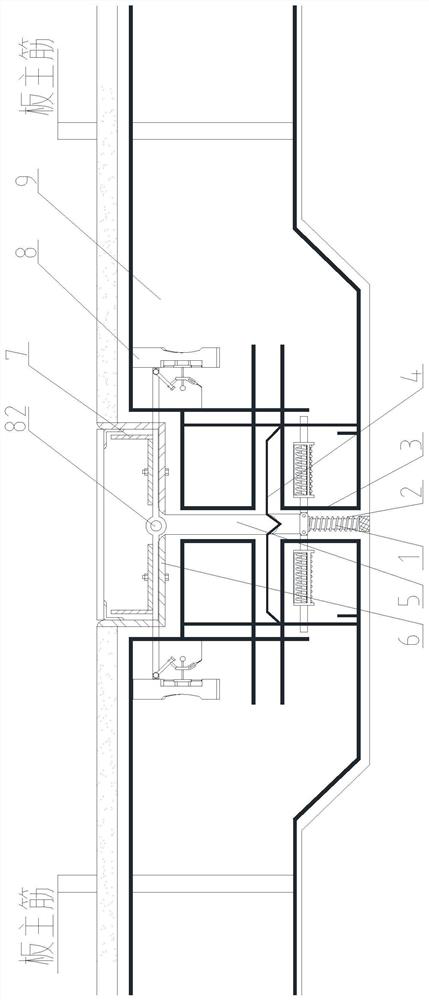

[0048]Seefigure 2 ,image 3 ,Figure 4 ,Figure 5 withFigure 6The present invention provides its technical solution, one based on the basement interconnector structure based on the soil steel sheet, including GB flexible filler 2 at the bottom of the crack 1, is provided at top of GB flexible filler 2, polyethylene plastic arranged to mesh The waterproof bar 3 is located in the crack 1, and the V-shaped water plate 4 is disposed at the top of the polyethylene plastic waterproof bar 3, which is filled in the crack 1 of the V-shaped soil steel plate 4, and the crack 1 The opening covering a layer of water expansion stopper rubber strip 6, each of the two sides of the water rubber strip 6 is disposed, and the angle steel 7 is connected to the water expansion stopper rubber strip 6 by the reinforcing structure 8 and is fixed. Wall 9.

[0049]Specifically, the reinforcing structure 8 includes two traveling rods 80, respectively, respectively, an elastic fastening assembly 81, respectively, cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com