Determination method, device and system for operation state of compressor

A technology for determining the operating state and method, applied in mechanical equipment, machine/engine, pump control, etc., can solve problems such as damage to compressor equipment, compressor output impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

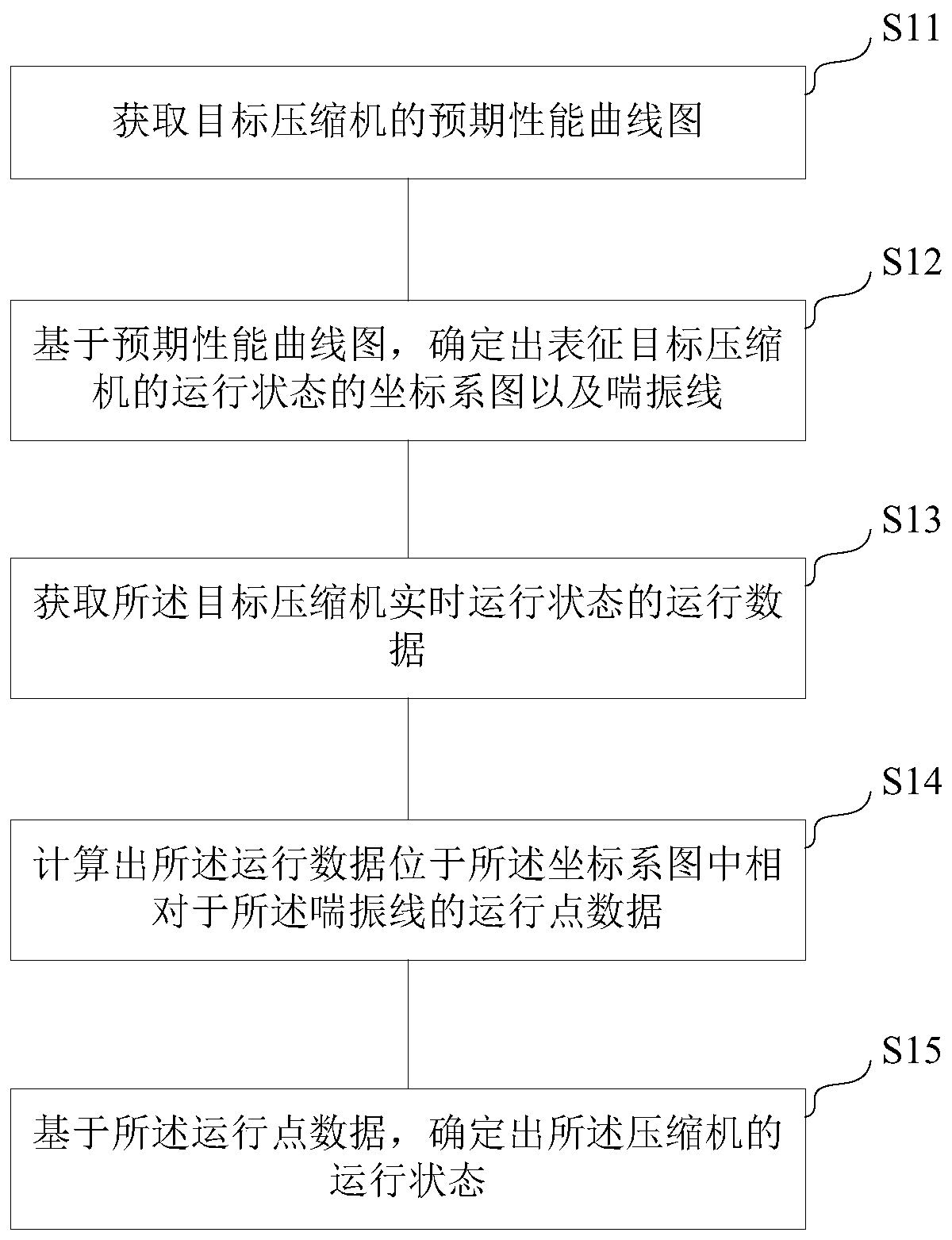

[0056]As mentioned in the background technology, the anti-surge control is the basic control in the compressor control, but the inventors found that the current surge control is based on the equipment characteristic data provided by the compressor manufacturer, and calculates the control safety points of multiple typical working conditions , when the actual compressor is running, once the above control safety point is touched, immediately open the anti-surge valve. This method can protect the equipment of the compressor to a certain extent, but because the equipment characteristic data given by the compressor manufacturer is based on the data obtained from the specific design working conditions, and the actual operation of the compressor, with the process control requirements The actual working condition will be different from the design working condition. In addition, the molecular weight change of the compressed gas will also affect the performance of the compressor. Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com