Gas water heater and control method thereof

A technology of gas water heaters and heat exchangers, which is applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problems of poor versatility of proportional valves, high outlet water temperature, and heavy load in the ignition process, etc. Outlet water temperature and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

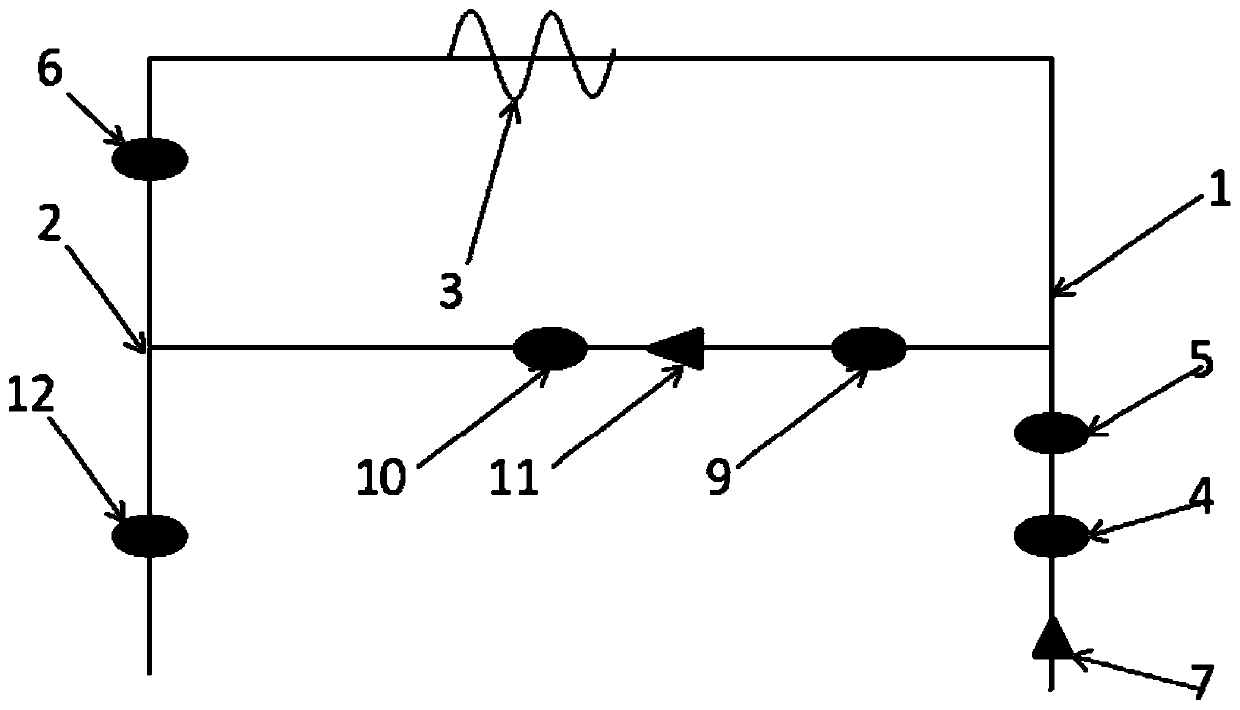

[0046] Such as figure 1 As shown, this embodiment introduces a gas water heater, which includes a body, and a heat exchanger 3 is installed in the body. The two ends of the heat exchanger 3 are respectively connected with the water inlet pipe 1 and the water outlet pipe 2. There is a water pump 7 for adjusting the water inlet flow rate.

[0047] In this embodiment, the water inlet pipe 1 of the gas water heater is installed with an inlet water temperature sensor 5 for detecting the inlet water temperature; An outlet water temperature sensor 6 for detecting the outlet water temperature is installed. Preferably, in order to improve the adaptability, a water pump 7, an inlet water flow sensor 4 and an inlet water temperature sensor 5 are sequentially arranged on the water inlet pipe 1 along the water flow direction, so that only the inlet pipe 1 of the existing ordinary gas water heater needs to be installed. Water end installs water pump 7 additionally, just can meet service r...

Embodiment 2

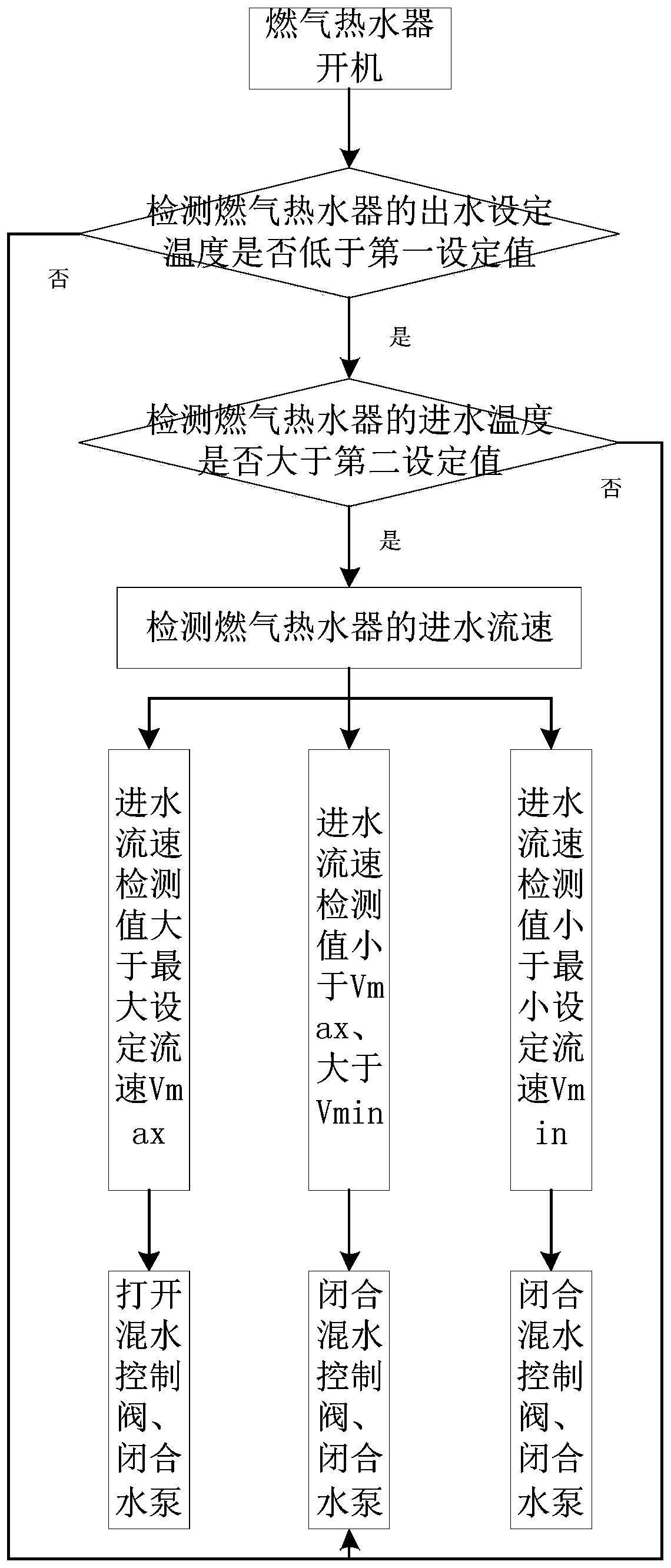

[0054] Such as figure 2 As shown, this embodiment introduces a control method applied to the gas water heater described in Embodiment 1 above. When the required heat load of the gas water heater is less than the minimum set value of the heat load, the heat exchanger of the gas water heater is controlled. Water diversion, or increase the flow rate, control the gas water heater to operate at a value greater than the minimum heat load setting.

[0055] Through the above control method, the gas water heater can use the increased water flow rate to adjust the outlet water temperature after combustion and heat exchange, thereby achieving the working condition that the gas water heater is suitable for low heat load demand and improving the use range of the gas water heater. In particular, the present application adopts the method of increasing the water intake of the gas water heater, so that the gas water heater does not have to work at the lowest load, and can also obtain a lower ...

Embodiment 3

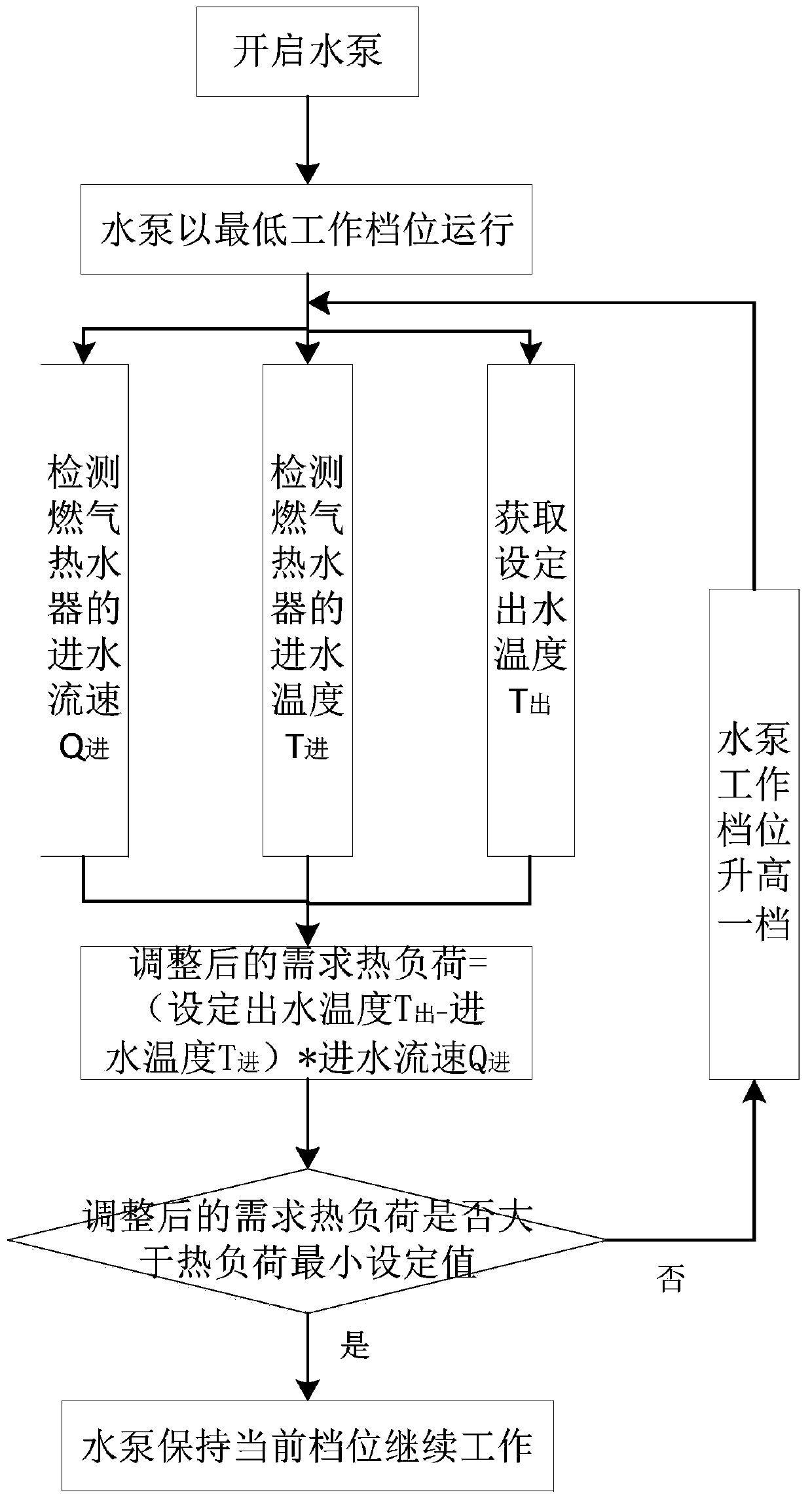

[0070] This embodiment introduces a control method based on the gas water heater described in Embodiment 2 above, which also has the following distinguishing technical features. When the demand heat load of the gas water heater is less than the minimum heat load setting, the water inlet flow rate of the gas water heater increase.

[0071] Through the above control method, the gas water heater can use the increased water flow rate to adjust the outlet water temperature after combustion and heat exchange, thereby achieving the working condition that the gas water heater is suitable for low heat load demand and improving the use range of the gas water heater. At the same time, through the above control method and device, the gas water heater can increase the water intake, so that the gas water heater does not need to work at the lowest load, and can also obtain a lower outlet water temperature.

[0072] In this embodiment, the gas water heater is detected to obtain the inlet wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com