Method for recycling flue gas waste heat of heating furnace during preparation of carbon disulfide

A carbon disulfide, preparation process technology, applied in lighting and heating equipment, machines using waste heat, machine operation and other directions, can solve the problem of not being able to discharge flue gas temperature to a lower temperature, etc., to save clean water consumption, reduce The effect of water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

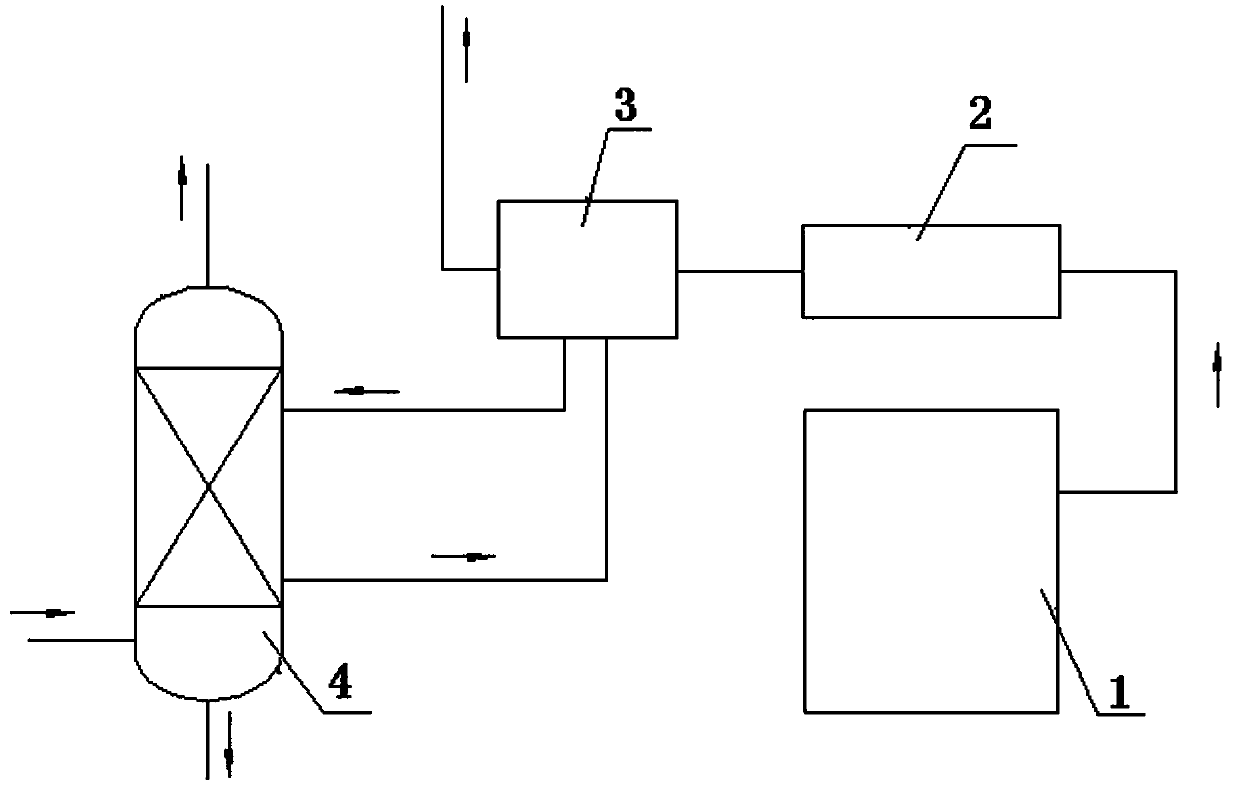

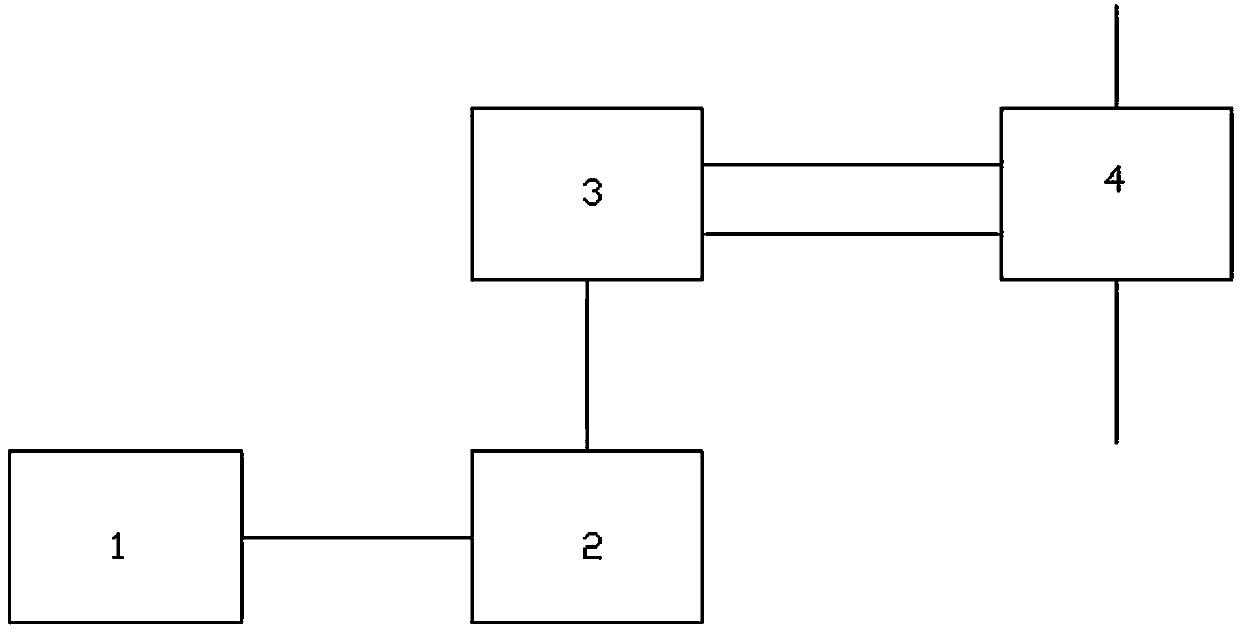

[0025] Such as figure 1 As shown, a device for recovering waste heat from heating furnace flue gas in the process of carbon disulfide preparation, including heating furnace 1, waste heat boiler 2 (a boiler used to absorb waste or residual heat, generating steam and steam that can be used is called waste heat Boiler (also called boiler), lithium bromide refrigeration unit 3 and carbon disulfide condenser 4, the exhaust port of the heating furnace 1 is connected to the waste heat boiler 2 through a pipe, and the high-temperature flue gas discharged from the exhaust port of the heating furnace 1 has a large impact on the waste heat The boiler 2 heats the water to make it into water vapor; the exhaust port of the waste heat boiler 2 is connected with the lithium bromide refrigeration unit 3 through a pipeline, that is, the flue gas heated by the waste heat boiler 2 has a temperature of 150°C, and lead flue gas into the lithium bromide refrigeration unit 3 to produce low-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com