Modular heating equipment

A heating equipment and modular technology, applied in the field of modular heating equipment, can solve the problems of inconvenient heating equipment, waste of transportation space, inability to heat a large amount of materials and a small amount of materials, etc., to achieve easy replacement, solve space waste, box body Detachable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

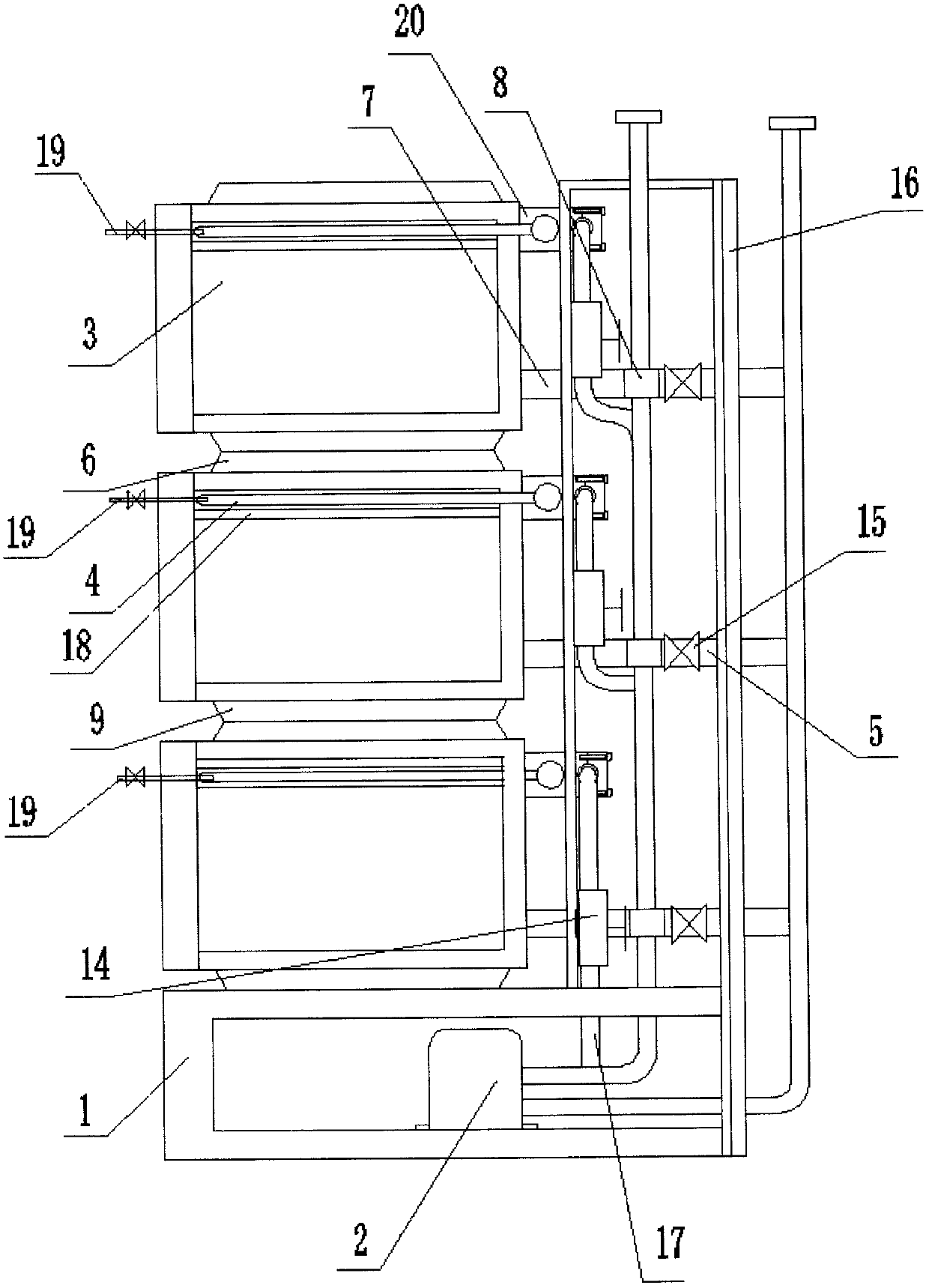

[0031] Such as Figure 1-2 As shown, a modular heating device includes a base 1, a compressor 2 is provided in the base 1, and a heating box and a heat pipe radiator. The heating box is provided on the base 1, and the heating box includes three slaves. The box body 3 is distributed from top to bottom and can be combined / detached. The condensing section 4 of the heat pipe radiator is arranged in the box body 3, and the evaporation section 5 of the heat pipe radiator is arranged outside the box body 3. The outlet of the machine 2 communicates with the condensation section 4, and the inlet of the compressor 2 communicates with the evaporation section 5.

[0032] The liquid working fluid in the heat pipe radiator evaporates into a low-pressure gas in the evaporation section 5. After being compressed into a high-temperature and high-pressure gas by the compressor 2, it enters the condensing section 4 of the heat pipe radiator arranged in the box 3 to release heat and becomes For high...

Embodiment 2

[0034] A modular heating device includes a base 1, a compressor 2 is provided in the base 1, and a heating box and a heat pipe radiator. The heating box is arranged on the base 1, and the heating box includes three top-to-bottom heating boxes. The boxes 3 are arranged in sequence and can be assembled / detached. The condensation section 4 of the heat pipe radiator is arranged in the box 3, and the evaporation section 5 of the heat pipe radiator is arranged outside the box 3. The compressor 2 The outlet is connected to the condensing section 4 and the inlet of the compressor 2 is connected to the evaporating section 5.

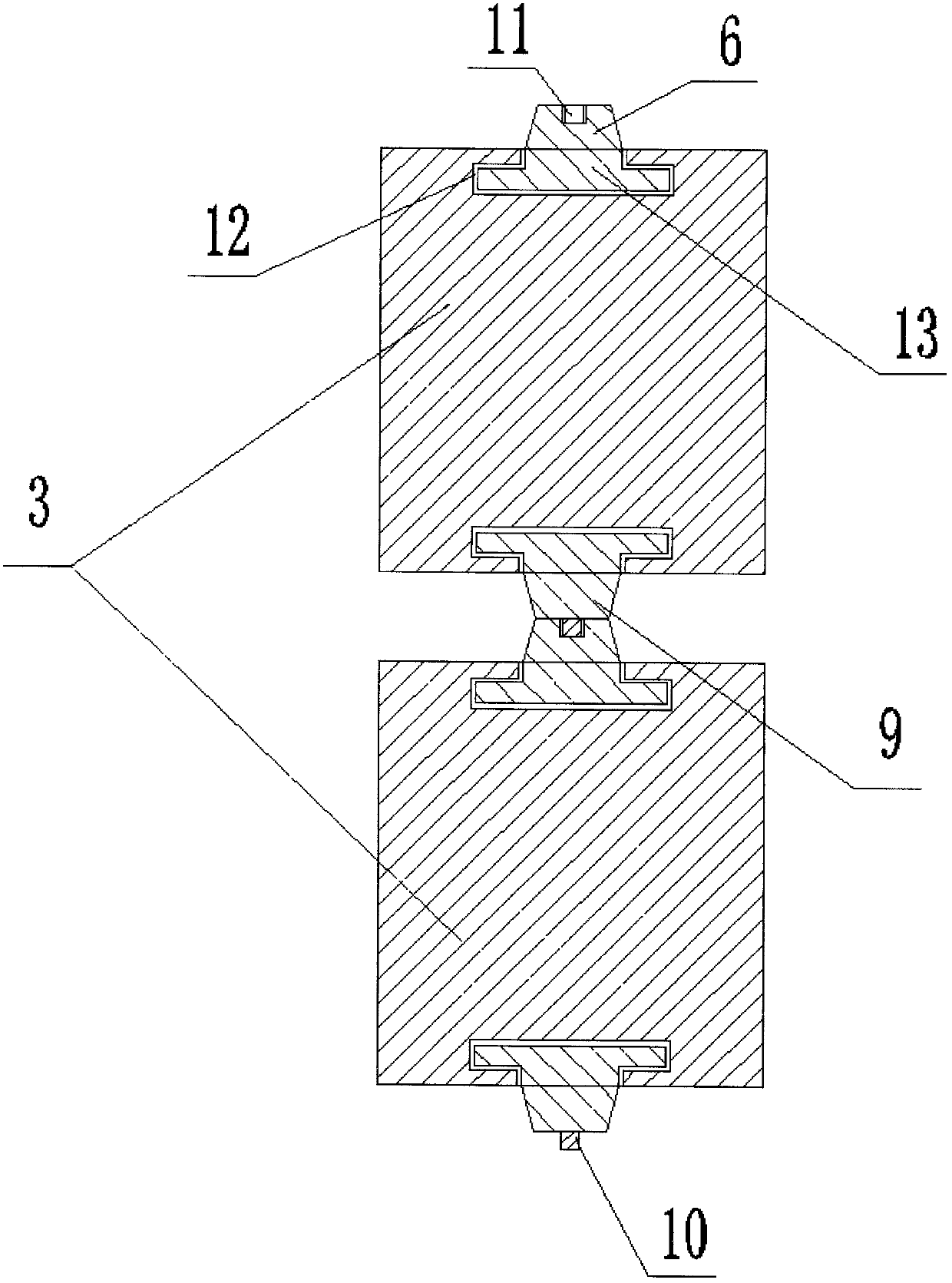

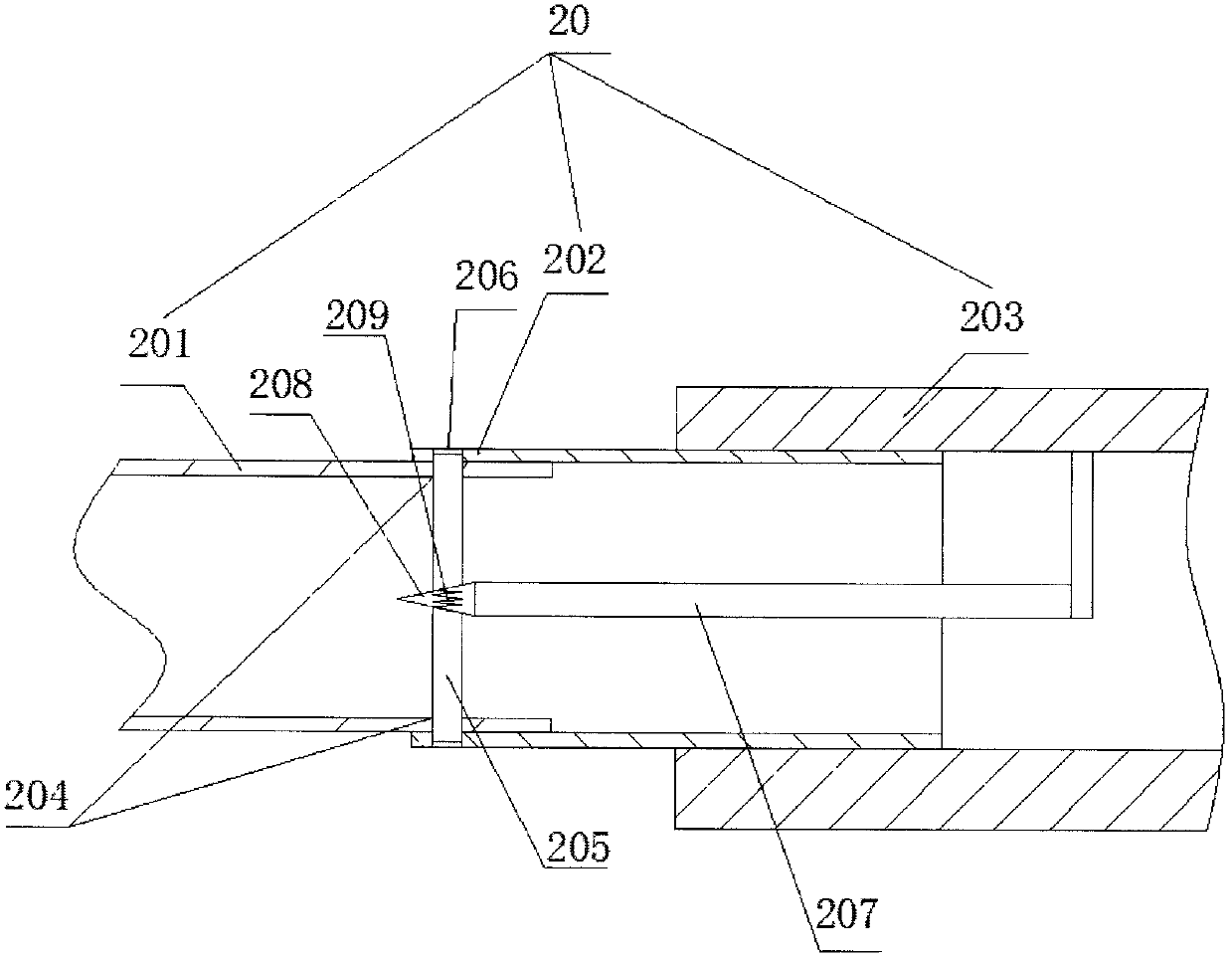

[0035] An upper fixing seat 6 is provided on the top of the box body 3, a lower fixing seat 9 is provided on the bottom of the box body 3, a screw 10 is provided on the lower fixing seat 9, and a screw hole 11 is provided on the upper fixing seat 6, two boxes adjacent to each other up and down. The body 3 is connected by a screw 10 and a screw hole 11, and the botto...

Embodiment 3

[0039] A modular heating device includes a base 1, a compressor 2 is provided in the base 1, and a heating box and a heat pipe radiator. The heating box is arranged on the base 1, and the heating box includes three top-to-bottom heating boxes. The boxes 3 are arranged in sequence and can be assembled / detached. The condensation section 4 of the heat pipe radiator is arranged in the box 3, and the evaporation section 5 of the heat pipe radiator is arranged outside the box 3. The compressor 2 The outlet is connected to the condensing section 4 and the inlet of the compressor 2 is connected to the evaporating section 5.

[0040] An upper fixing seat 6 is provided on the top of the box body 3, a lower fixing seat 9 is provided on the bottom of the box body 3, a screw 10 is provided on the lower fixing seat 9, and a screw hole 11 is provided on the upper fixing seat 6, two boxes adjacent to each other up and down. The body 3 is connected by a screw 10 and a screw hole 11, and the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com