Air cooler with air conditioning system

A technology for air conditioning systems and air coolers, applied in water shower coolers, heat exchanger types, direct contact heat exchangers, etc. The problem of dirt and other problems is eliminated, and the effect of convenient installation and use, effective temperature difference increase and compact system structure is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

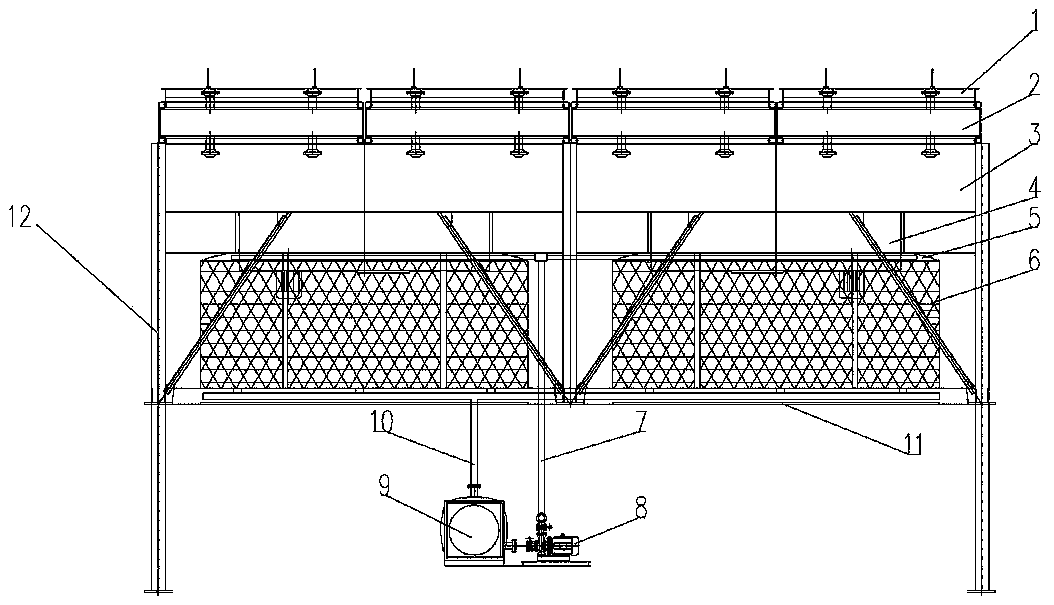

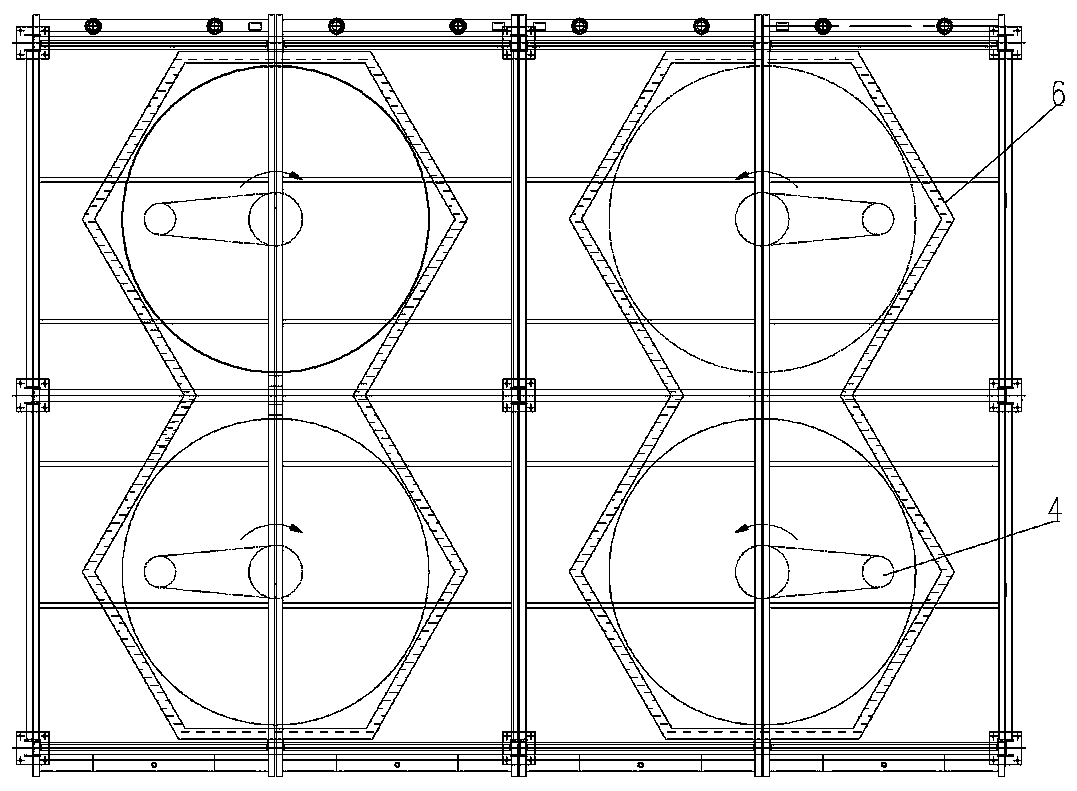

[0019] Examples, as attached figure 1 , figure 2 As shown, an air cooler with an air conditioning system includes an air cooler frame 12, and the air cooler frame 12 is provided with an air conditioning system, a fan shroud 5, a blower 4, an air chamber 3, a finned tube bundle 2, and an air cooler blinds1.

[0020] The air conditioning system includes a wet curtain 6, a water pump 8, a water tank 9, a water supply pipeline 7, and a water return pipeline 10.

[0021] The wet curtain 6 is arranged on the lower part of the air cooler frame 12, and the bottom of the wet curtain 6 is provided with a windshield 11, and the windshield 11 is used to prevent the bottom air from directly entering the blower 4 without passing through the wet curtain 6; On the upper side of the wind plate 11, one end of the return pipe 10 communicates with the bottom of the wet curtain 6, and the other end of the return pipe 10 communicates with the water tank 9, and the water tank 9 communicates with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap