Weld joint ultrasonic phased array detection data intelligent analysis method based on deep learning

An ultrasonic phased array and data detection technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and material analysis. Control array detection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are further described in detail below.

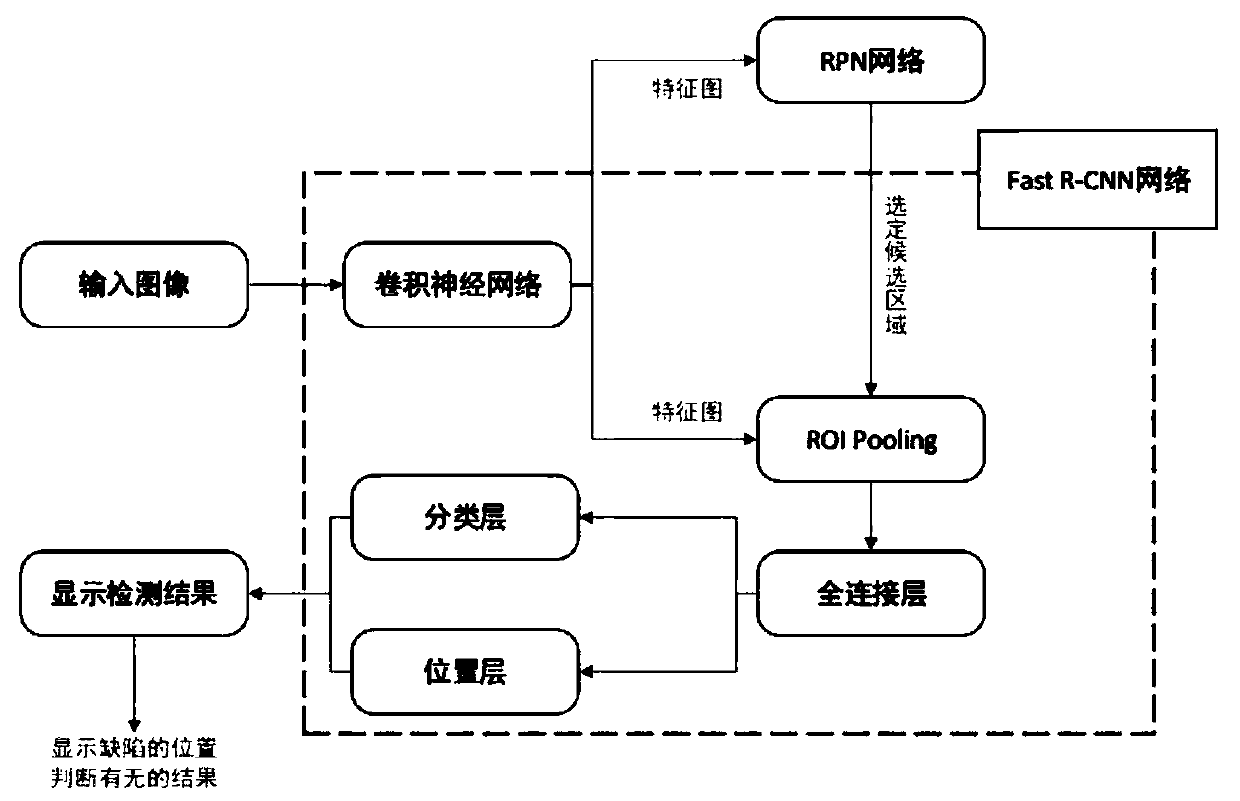

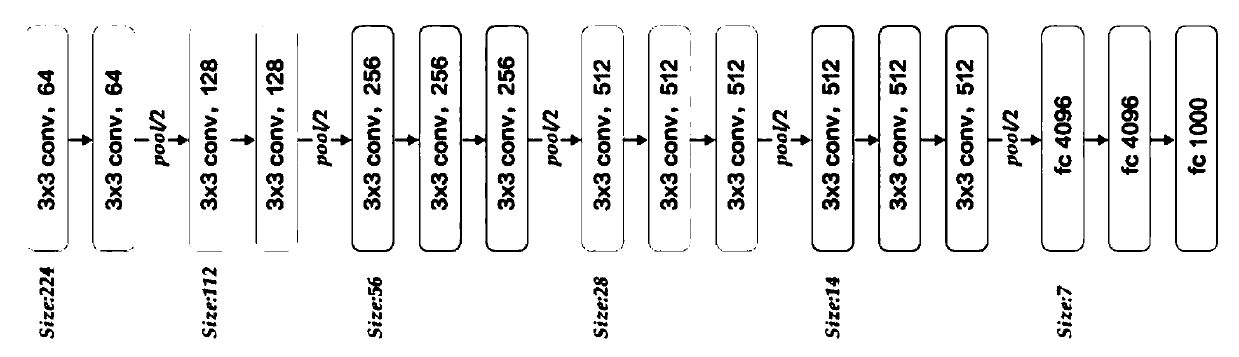

[0036] This embodiment provides a method for intelligent analysis of welding seam ultrasonic phased array detection data based on deep learning. The method includes the following steps:

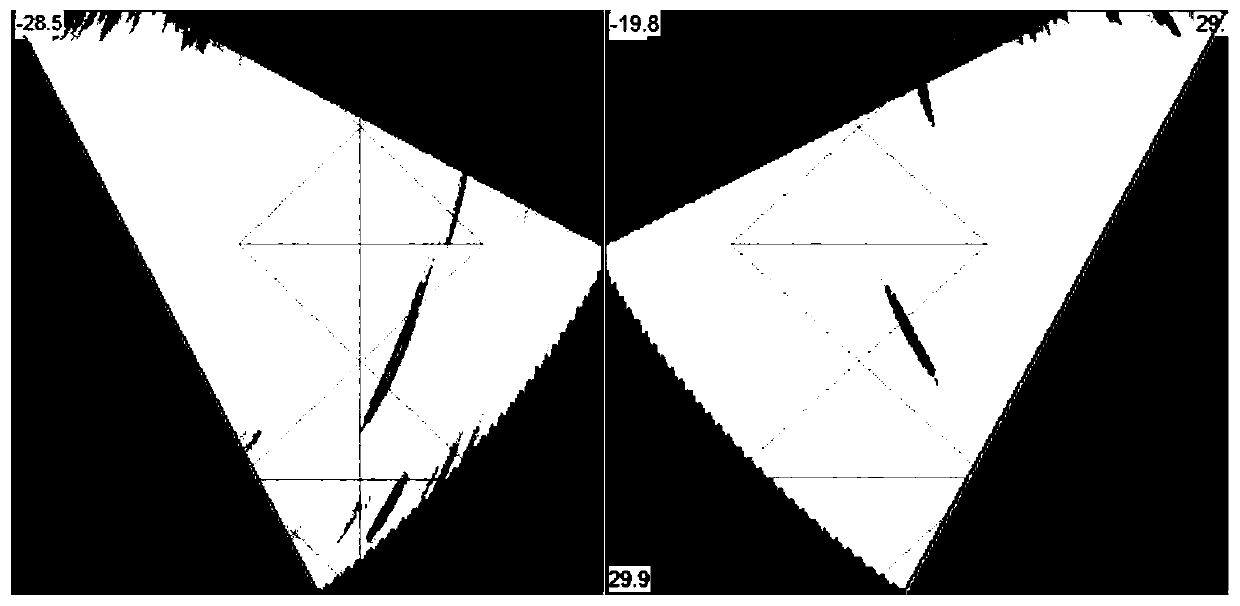

[0037] S1: Perform data sampling. Select steel plates with a thickness of 12, 14, 18, 20, 24, and 30 mm, and the ratio of X-shaped welds to V-shaped welds in the steel plate welds is 1:1. The phased array is then used to inspect the welds of the steel plates, and the phased array weld slices are sampled every 1 mm to obtain a series of S-scan pictures. In order to make the number of samples sufficient and to improve the generalization ability of the deep network, scan the other side of the same weld to obtain data, such as figure 1 shown.

[0038] S2: Perform preprocessing. Divide the S-scan pictures in step S1 into a training set and a verification set according to a ratio of 1:1, and keep the propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com