Greenhouse micro-spraying irrigation facility based on environmental information and control method thereof

An environmental information, plastic greenhouse technology, applied in the fields of botanical equipment and methods, electrical program control, program control in sequence/logic controllers, etc. The effect of saving labor, saving irrigation water, and promoting plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be described below in conjunction with the drawings and embodiments.

[0037]

[0038] This embodiment provides a greenhouse micro-spray irrigation facility and its control method based on environmental information, which is used to automatically perform micro-spray irrigation on crops in a plastic greenhouse with a film and a skeleton.

[0039] In this embodiment, the plastic greenhouse is 8 meters wide and 40 meters long. Soil cultivation is used to grow lettuce. The fertilizer is self-made decomposed organic fertilizer, which is applied once in the form of base fertilizer before planting.

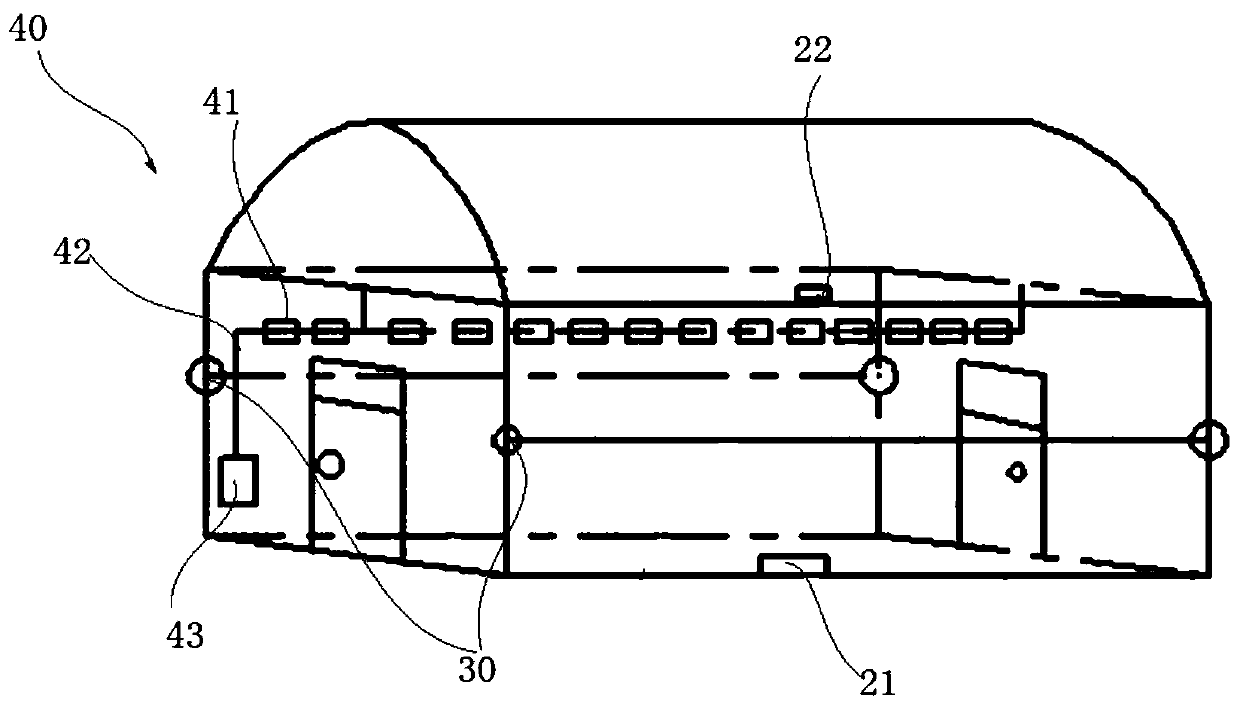

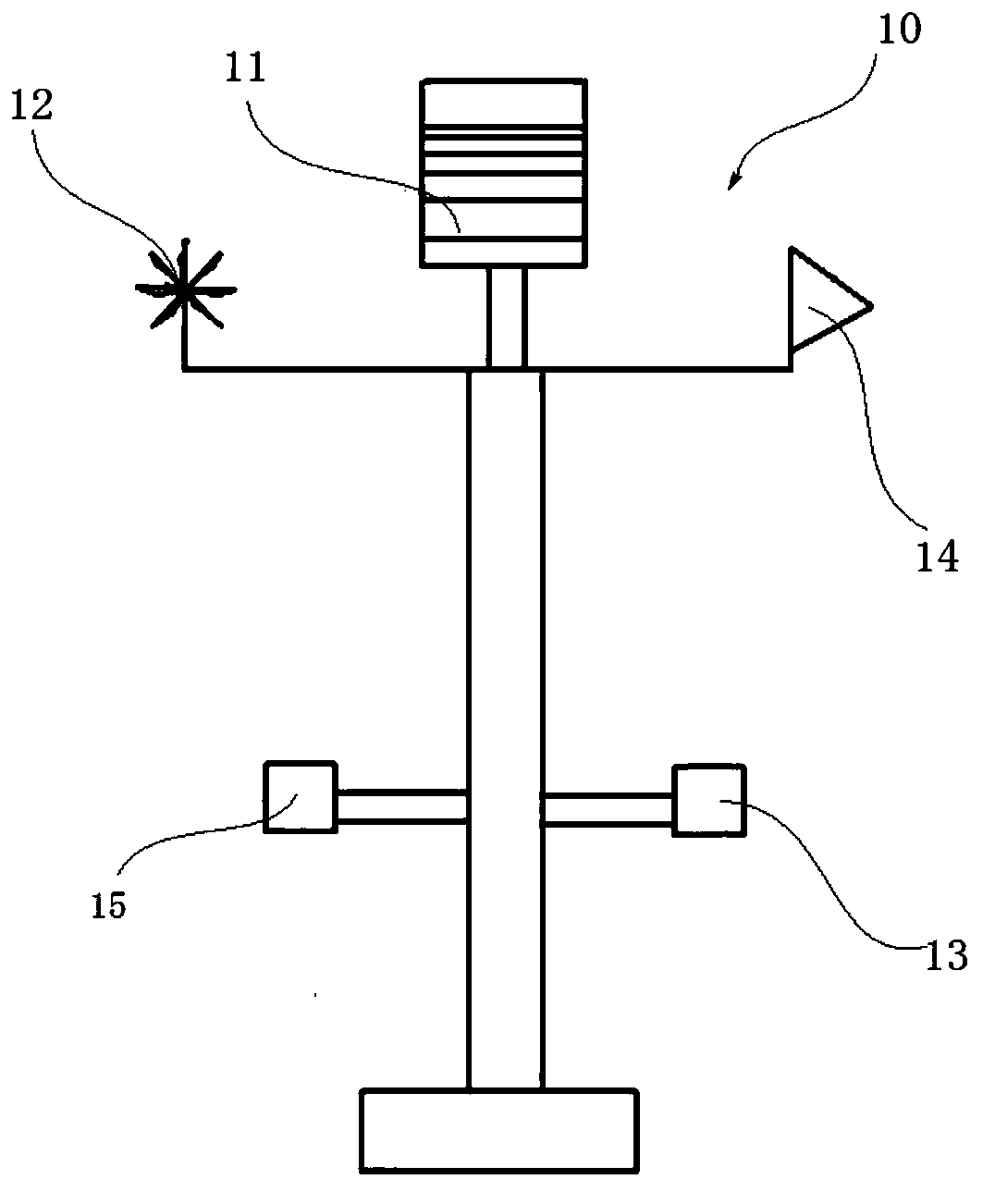

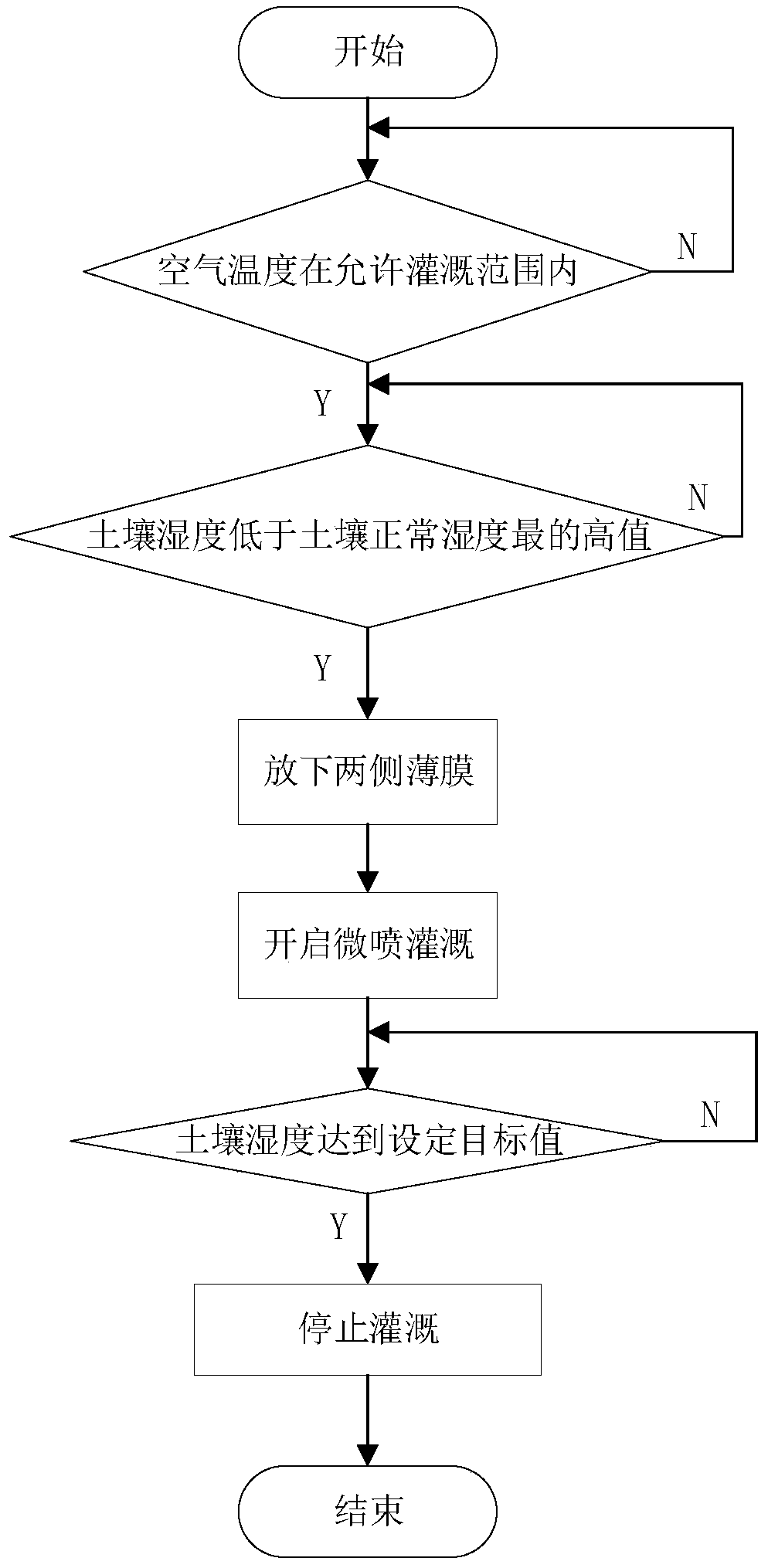

[0040] figure 1 It is an indoor schematic diagram of micro-spray irrigation facilities for greenhouses based on environmental information according to an embodiment of the present invention, figure 2 It is a schematic diagram of an outdoor weather monitoring system for micro-spray irrigation facilities in greenh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com