Rotary vane pump stator inner contour curve design method based on normal distribution function

A technology of normal distribution function and curve design, applied in geometric CAD and other directions, can solve problems such as reducing product service life and mechanical shock, and achieve the effects of reducing the impact of mechanical shock, improving service life, and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

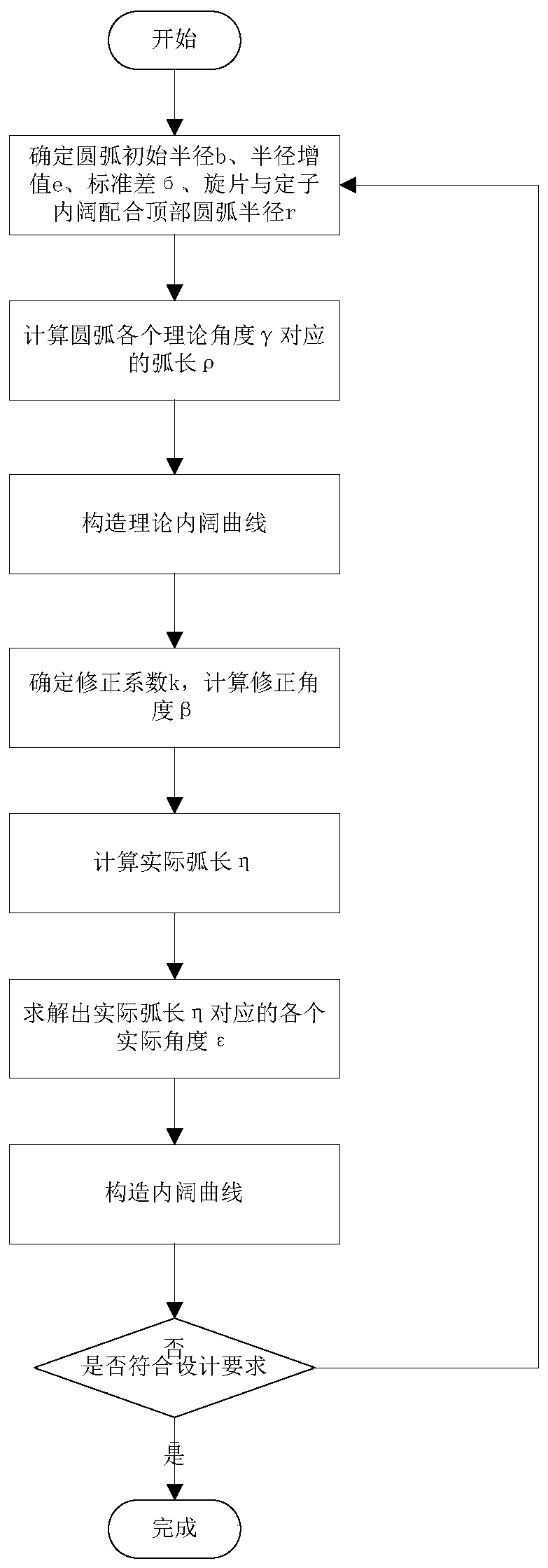

[0036] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] A method for designing the stator inner profile curve of a rotary vane pump based on a normal distribution function, comprising the following steps:

[0038] Step 1: According to the design requirements, determine the initial values of arc radius B, radius increment e, top arc radius r and standard deviation σ of the inner width of the rotary vane and stator, and set B=7.5, e=2.5, r=2.5,

[0039] Step 2: Calculate the theoretical arc length corresponding to each theoretical angle γ of the arc

[0040] In the formula, x is the theoretical angle, a total of 181 points are substituted into the angle from 0° to 180°, using Find the theoretical arc length corresponding to each degree point

[0041]

[0042]

[0043]

[0044]

[0045]

[0046]

[0047]

[0048]

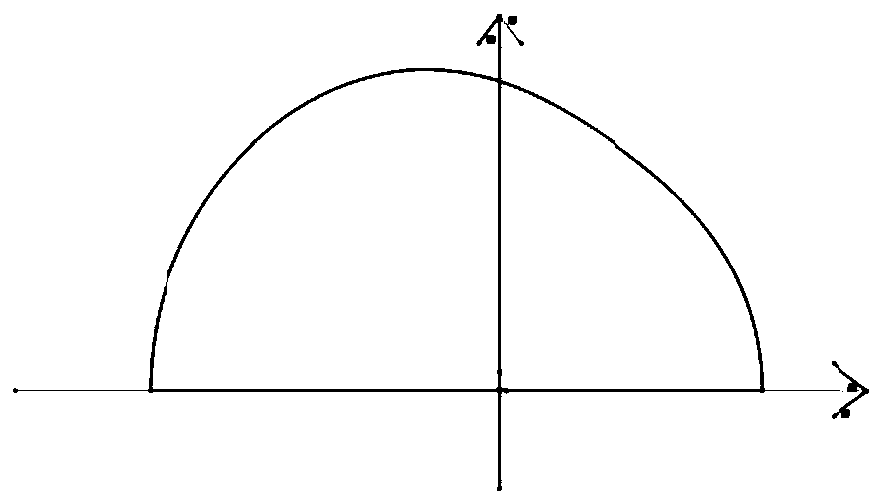

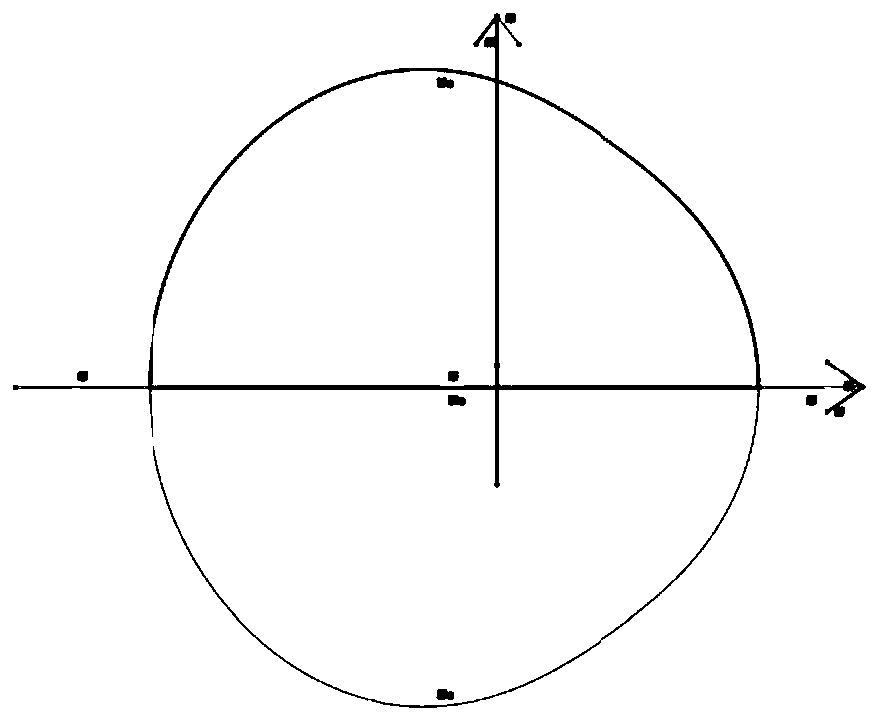

[0049] Step 3: Construct the theoretica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com