Shoe sole size classification method based on machine vision

A technology of machine vision and classification method, applied in the fields of instruments, computer parts, character and pattern recognition, etc., can solve the problems of low recognition accuracy, wrong size judgment, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

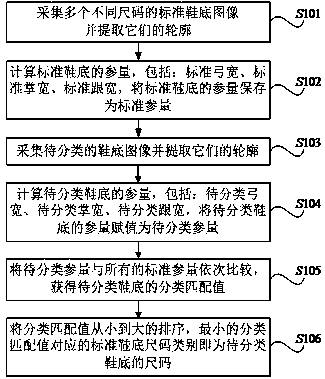

[0072] The sole size classification method based on machine vision, it can pass such as figure 1 The flow shown is realized, and its steps include the following:

[0073] Step S101: Utilize the industrial camera to obtain standard shoe sole images of different sizes, save the standard shoe sole images to the industrial computer, and extract the stored standard shoe sole images of the sole outline, the calculation formula is:

[0074]

[0075] Wherein f (x, y) is the brightness value at the pixel point (x, y) of the standard sole image, and r is the segmentation threshold set;

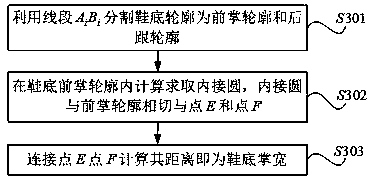

[0076] Step S102: Calculate the parameters of the standard sole through the sole profile of the standard sole image, including: standard bow width Standard Palm Width standard heel width Where i represents the size category of the sole, i∈(1,2,3,...,n), the specific calculation process is described in the figure 2 , image 3 , Figure 4 , which will be described in detail below, and the par...

Embodiment example 2

[0087] Implementation case 2: This implementation case is basically the same as implementation case 1, and the special features are as follows:

[0088] Key of the present invention is the algorithm of the sole parameter that obtains sole image in step S102 and step S104, comprises: arch width, palm width, heel width, will be described in detail as follows:

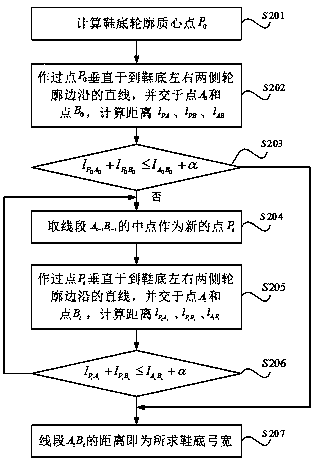

[0089] ① The specific algorithm steps of the bow width are as follows figure 2 As shown, the calculation diagram is as follows Figure 5 As shown, the specific process is as follows:

[0090] Step S201: Calculate the centroid point of the sole contour of the standard sole image (501), its calculation formula is:

[0091]

[0092] where S 0 is the area enclosed by the outline of the sole, f(x,y) is the brightness value of the point (x,y), and r is the set segmentation threshold.

[0093] Step S202: From the centroid point At (501), two straight lines perpendicular to the contour edges on the left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com