Lithium ion secondary battery

A secondary battery, lithium ion technology, applied in secondary batteries, lithium storage batteries, batteries, etc., can solve problems such as battery performance degradation, and achieve the effect of improving life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

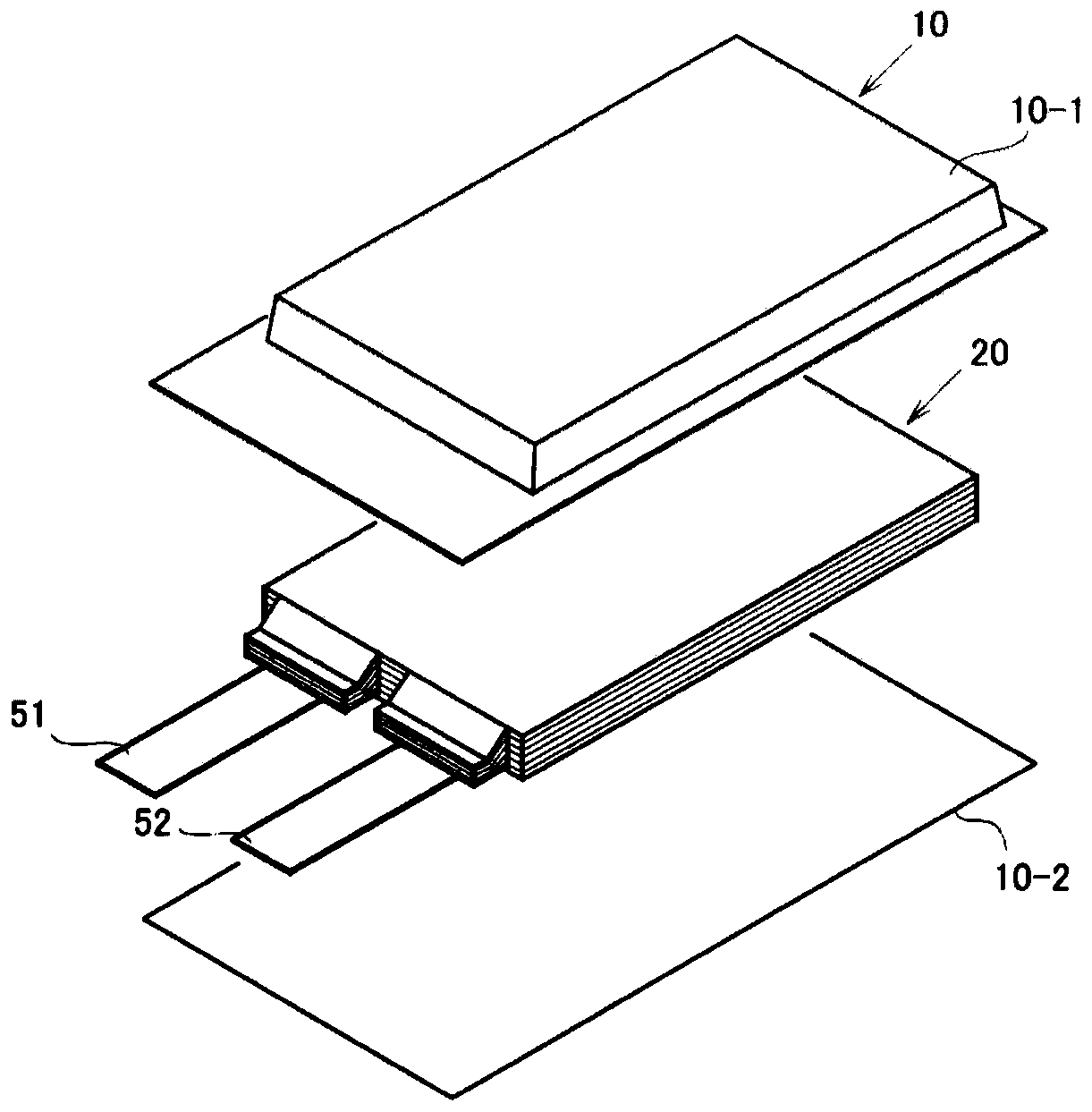

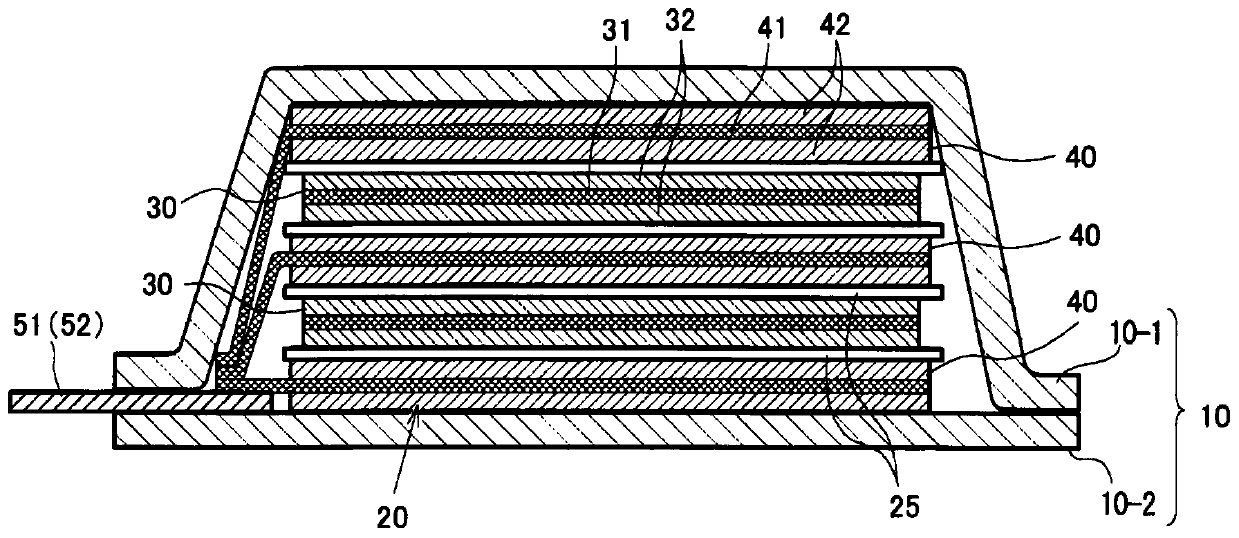

Image

Examples

Embodiment 1~2 and comparative example 1~5

[0148] (positive electrode)

[0149] Will Li 1.15 Ni 0.3 mn 0.55 o 2 , spherical carbon, flake carbon, and polyvinylidene fluoride (PVdF) were uniformly mixed to prepare a positive electrode mixture. Here, the weight ratio of each component in the positive electrode mixture is set as Li 1.15 Ni 0.3 mn 0.55 o 2 : Spherical carbon: Flake carbon: PVdF=93:3:1:3. The prepared positive electrode mixture was dispersed in N-methyl-2-pyrrolidone (NMP) to prepare positive electrode slurry. The positive electrode slurry is evenly coated on the aluminum foil used as the positive electrode current collector, dried at 120°C, and further pressed to obtain a positive electrode with a weight per unit area of 23.8g / cm 2 , Positive electrode density 3.0g / cm 3 positive pole.

[0150] (negative electrode)

[0151] 50% carbon-coated silicon oxide (SiOC) with a particle size of 5 μm (weight ratio is as follows. Coated carbon: silicon oxide = 5:95), fibrous carbon, and polyacrylic acid ...

Embodiment 3~4 and comparative example 6

[0166] (positive electrode)

[0167] Will Li 1.15 Ni 0.3 mn 0.55 o 2 , spherical carbon, flaky carbon, and polyvinylidene fluoride (PVdF) were uniformly mixed to prepare a positive electrode mixture. Here, the weight ratio of each component in the positive electrode mixture is set as Li 1.15 Ni 0.3 mn 0.55 o 2 : Spherical carbon: Flake carbon: PVdF=93:3:1:3. The prepared positive electrode mixture was dispersed in N-methyl-2-pyrrolidone (NMP) to prepare positive electrode slurry. The positive electrode slurry is evenly coated on the aluminum foil used as the positive electrode current collector, dried at 120°C, and further pressed to obtain a positive electrode with a weight per unit area of 23.8g / cm 2 , Positive electrode density 3.0g / cm 3 positive pole.

[0168] (negative electrode)

[0169] 50% carbon-coated silicon oxide (SiOC) with a particle size of 5 μm (weight ratio is as follows. Coated carbon: silicon oxide = 5:95), spherical carbon, and polyacrylic aci...

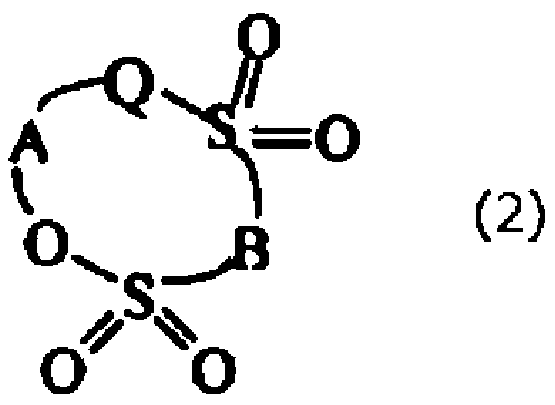

Embodiment 5~11 and comparative example 7

[0181] The preparation method of the electrolyte is the same as in Example 3, and the components are as listed in Table 3. In battery evaluation, the current value of constant current charging was set to 0.3C, the constant voltage charging was not performed, the current value of constant current discharge was set to 0.3C, and the number of cycles was set to 150. Other than that, batteries were fabricated and evaluated in the same manner as in Example 3. From the obtained results, the capacity retention rate and the resistance increase rate were calculated. The results are described in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com