A kind of preparation method of matsutake mask liquid

A technology of mask liquid and matsutake, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of production technology control and change, and achieve remarkable moisturizing and whitening effects without irritation and side effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

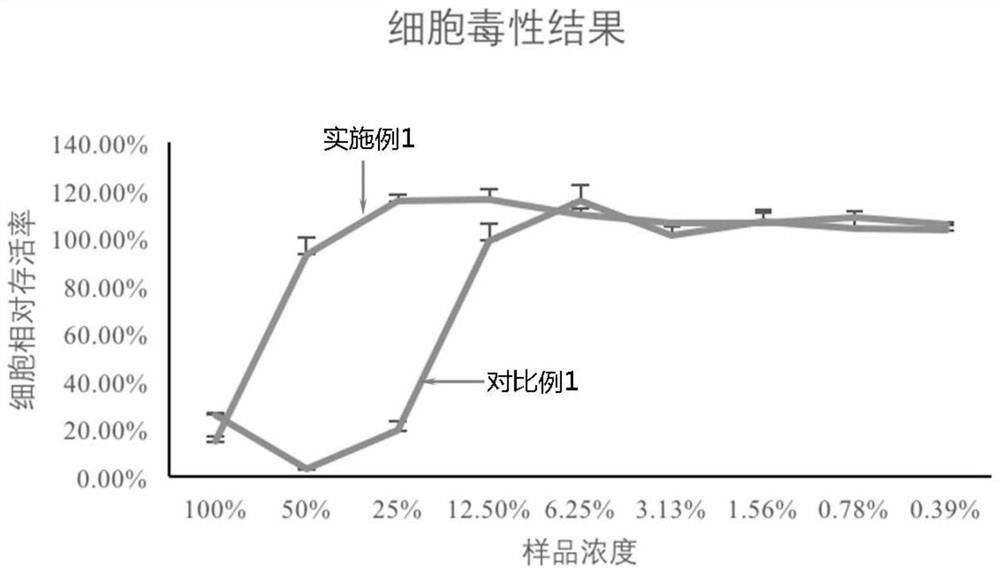

Embodiment 1

[0051] This embodiment is used to illustrate the preparation method of facial mask liquid of the present invention.

[0052] 1. Raw material processing (food grade)

[0053] Oatmeal: Superfine the fried oatmeal. The particle size is 80 mesh after pulverization, and the particle size after ultrafine pulverization is 15um. Mix 1:5 (g / ml) with water and make a slurry. After 15 minutes of ultrasonic extraction, take the filtrate as the oat pretreatment solution.

[0054] Matsutake: washed, sliced; 1:5 (g / ml) mixed with water and beaten, and 15 minutes after ultrasonic extraction, the filtrate was taken as matsutake pretreatment solution.

[0055] Dendrobium: Wash and cut the stem of Dendrobium; mix it with water at a ratio of 1:5 (g / ml) and make a pulp. After 15 minutes of ultrasonic extraction, take the filtrate as the pretreatment solution of Dendrobium.

[0056] Radix Notoginseng: wash Radix Notoginseng; 1:5 (g / ml) is mixed with water and beating, and after 15 minutes of ult...

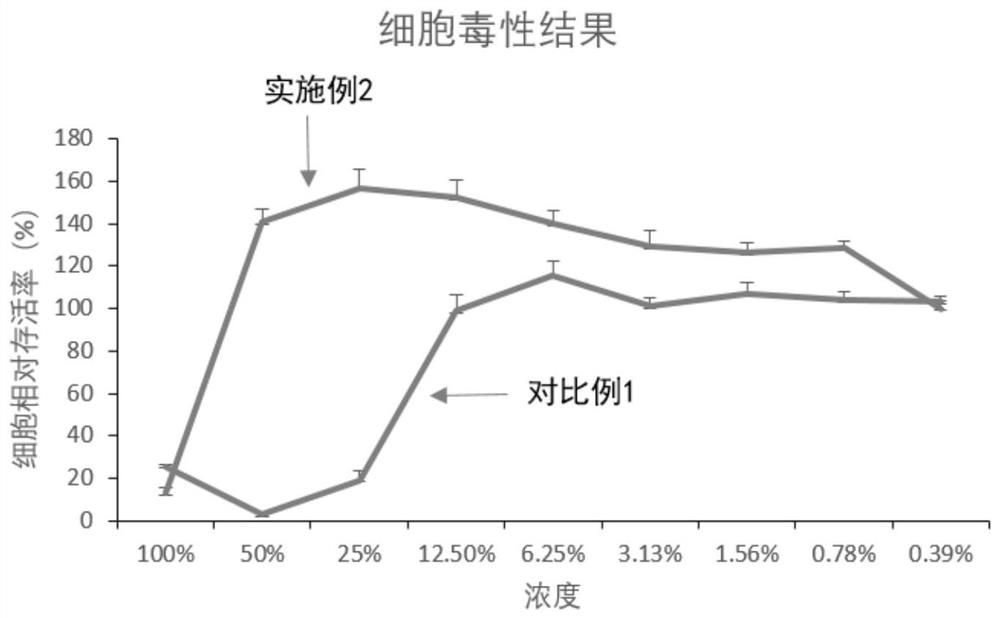

Embodiment 2

[0070] This embodiment is used to illustrate the preparation method of facial mask liquid of the present invention.

[0071] 1. Raw material processing (food grade)

[0072] Oatmeal: Superfine the fried oatmeal. The particle size is 50 mesh after pulverization, and the particle size after ultrafine pulverization is 20um. Mix 1:5 (g / ml) with water and make a slurry. After 15 minutes of ultrasonic extraction, take the filtrate as the oat pretreatment solution.

[0073] Matsutake: washed, sliced; 1:5 (g / ml) mixed with water and beaten, and 15 minutes after ultrasonic extraction, the filtrate was taken as matsutake pretreatment solution.

[0074] Radix Notoginseng: wash Radix Notoginseng; 1:5 (g / ml) is mixed with water and beating, and after 15 minutes of ultrasonic extraction, the filtrate is taken as Notoginseng pretreatment solution.

[0075] Dendrobium: Wash and cut the stem of Dendrobium; mix it with water at a ratio of 1:5 (g / ml) and make a pulp. After 15 minutes of ultra...

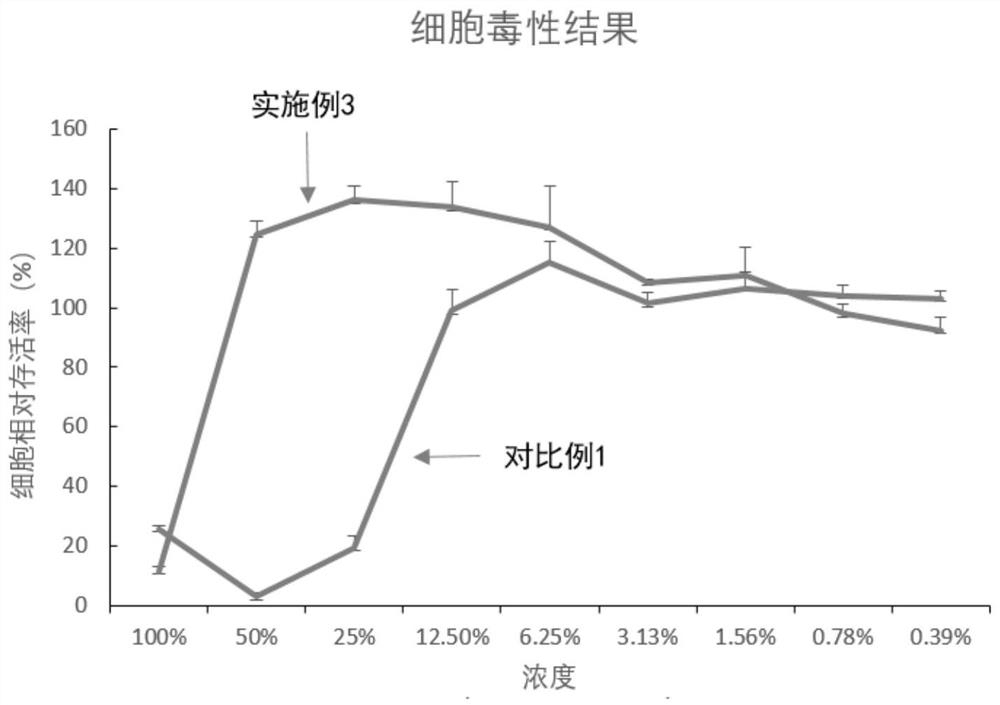

Embodiment 3

[0090] This embodiment is used to illustrate the preparation method of facial mask liquid of the present invention.

[0091] 1. Raw material processing (food grade)

[0092] Oatmeal: Superfine the fried oatmeal. The particle size is 50 mesh after pulverization, and the particle size after ultrafine pulverization is 20um. Mix 1:5 (g / ml) with water and make a slurry. After 15 minutes of ultrasonic extraction, take the filtrate as the oat pretreatment solution.

[0093] Matsutake: washed, sliced; 1:5 (g / ml) mixed with water and beaten, and 15 minutes after ultrasonic extraction, the filtrate was taken as matsutake pretreatment solution.

[0094] Radix Notoginseng: wash Radix Notoginseng; 1:5 (g / ml) is mixed with water and beating, and after 15 minutes of ultrasonic extraction, the filtrate is taken as Notoginseng pretreatment solution.

[0095] Dendrobium: Wash and cut the stem of Dendrobium; mix it with water at a ratio of 1:5 (g / ml) and make a pulp. After 15 minutes of ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com