A multi-component composite adsorption material for removing vanadium, its preparation method and application

An adsorption material and multi-component composite technology, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve problems that cannot meet the development situation, achieve pollution reduction, good adsorption and catalytic performance, and avoid The effect of particle aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

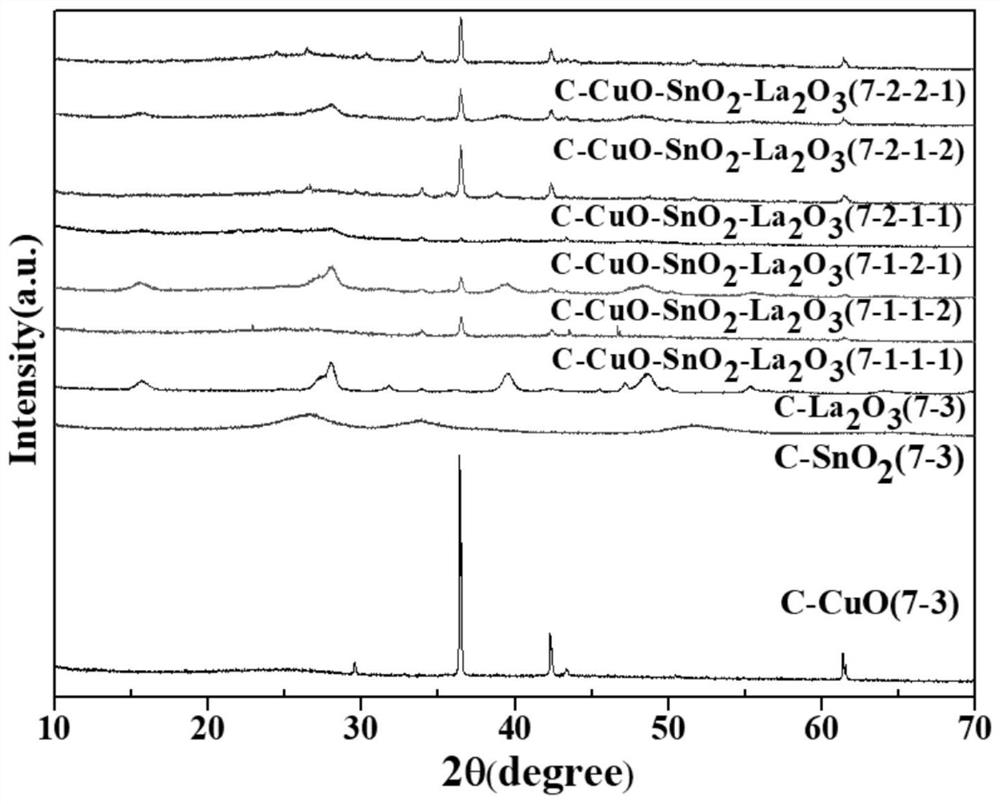

[0028] A multi-component composite adsorption material for removing vanadium, with CuO-SnO 2 -La 2 o 3 The composite oxide is used as the active component, and the activated carbon is used as the porous support matrix, where CuO-SnO 2 -La 2 o 3 The weight ratio of composite oxide to activated carbon is 30:70, CuO, SnO 2 , La 2 o 3 The molar ratio is 2:1:1.

[0029]The preparation method of this multiple composite adsorption material specifically comprises: 14.8309g activated carbon and 1.8960g tin protochloride (0.01mol), 8.6600g lanthanum nitrate (0.02mol), 3.7512g copper nitrate (0.02mol) are added to 40mL concentration respectively Stir and dissolve in 0.20mol / L dilute nitric acid, then add ammonia solution to adjust the pH to 10 under magnetic stirring, then transfer to the ultrasonic and microwave combined reactor after sufficient magnetic stirring, turn on the microwave ultrasonic dual-function device, and simultaneously use 1000W ultrasonic and React under the c...

Embodiment 2

[0039] A multi-component composite adsorption material for removing vanadium, with CuO-SnO 2 -La 2 o 3 The composite oxide is used as the active component, and the activated carbon is used as the porous support matrix, where CuO-SnO 2 -La 2 o 3 The weight ratio of composite oxide to activated carbon is 30:70, CuO, SnO 2 , La 2 o 3 The molar ratio is 1:1:1.

[0040] The preparation method of this multi-component composite adsorption material specifically includes: adding 12.9748g of activated carbon and 1.8960g of tin protochloride (0.01mol), 8.6600g of lanthanum nitrate (0.02mol), and 1.8756g of copper nitrate (0.01mol) to 40mL with a concentration of 0.20 Stir and dissolve in mol / L dilute nitric acid, then add ammonia solution under magnetic stirring to adjust the pH to 7, and then transfer to the ultrasonic microwave combination reactor after sufficient magnetic stirring, turn on the microwave ultrasonic dual-function device, and simultaneously use 800W ultrasonic and...

Embodiment 3

[0042] A multi-component composite adsorption material for removing vanadium, with CuO-SnO 2 -La 2 o 3 The composite oxide is used as the active component, and the activated carbon is used as the porous support matrix, where CuO-SnO 2 -La 2 o 3 The weight ratio of composite oxide to activated carbon is 30:70, CuO, SnO 2 , La 2 o 3 The molar ratio is 1:1:2.

[0043] The preparation method of this multiple composite adsorption material specifically comprises: 20.5770g activated carbon and 1.8960g tin protochloride (0.01mol), 17.3200g lanthanum nitrate (0.04mol), 1.8756g copper nitrate (0.01mol) are added to 40mL concentration respectively Stir and dissolve in 0.20mol / L dilute nitric acid, then add ammonia solution to adjust the pH to 12 under magnetic stirring, then transfer to the ultrasonic and microwave combination reactor after sufficient magnetic stirring, turn on the microwave and ultrasonic dual-function device, and simultaneously use 1200W ultrasonic and React fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com