Direct-drive transmission powder concentrator with motor placed inside rotor

A powder separator and rotor technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem of large pressure difference between wind and material outlet, reduce the maintenance times of powder separator, reduce Fan operation power consumption and other issues, to achieve the effect of reducing local pressure difference, reducing equipment maintenance times, reducing fan power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

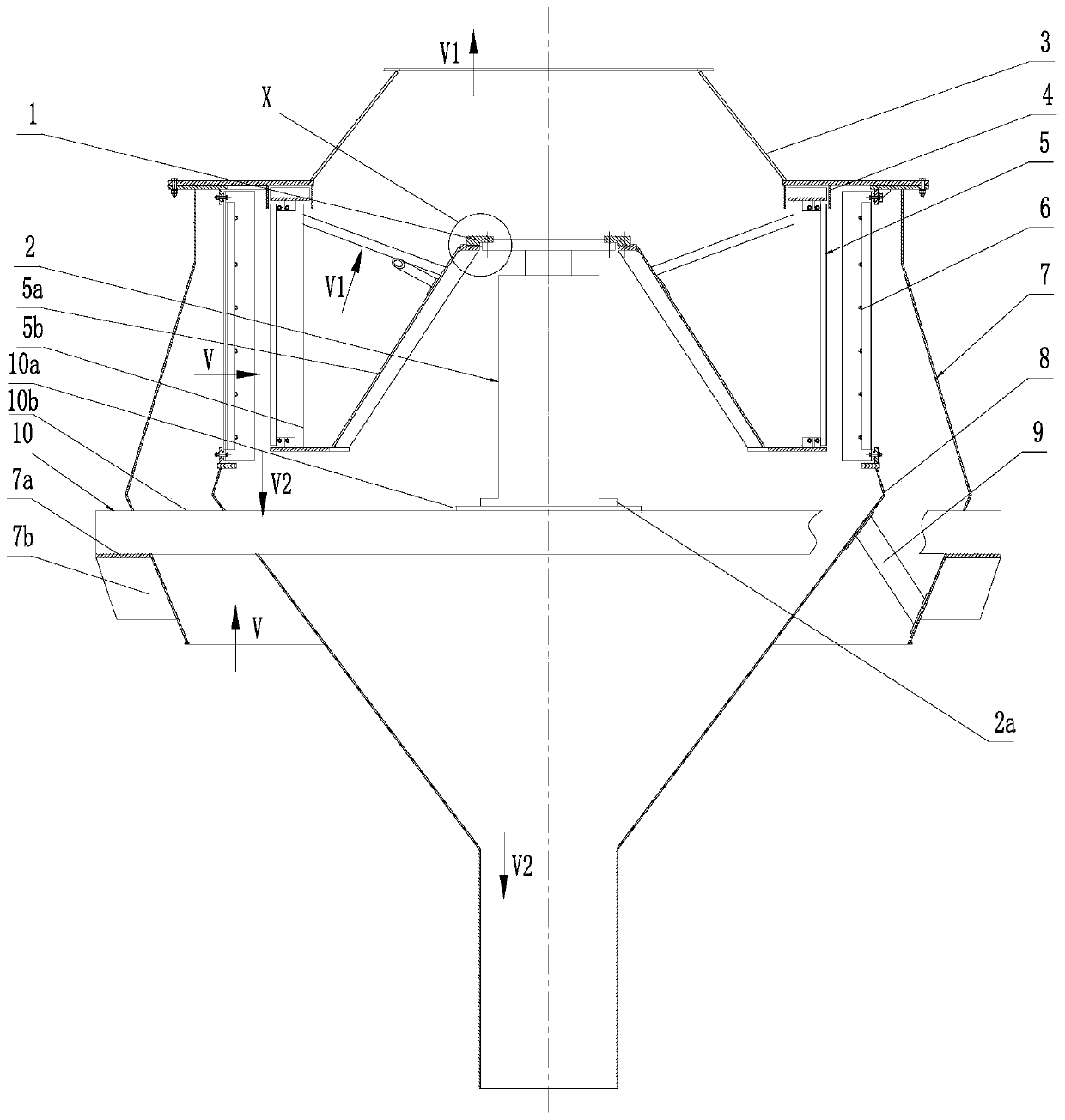

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

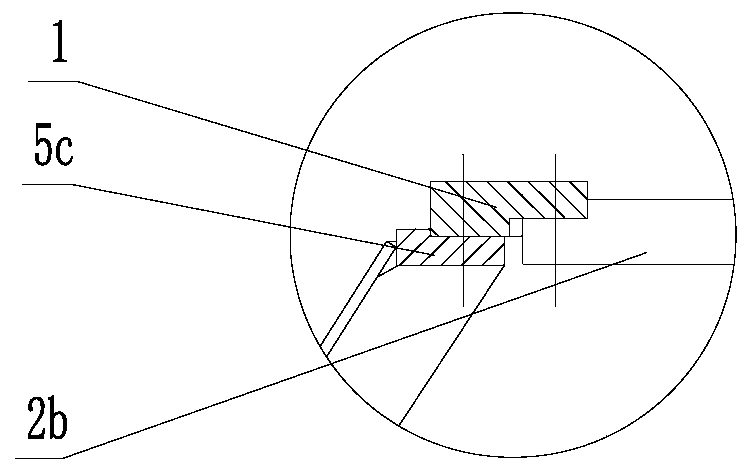

[0023] see figure 1 and 2 , a direct-drive powder separator with a motor placed inside the rotor, comprising an upper housing 3, a lower housing 7, a motor 2, a rotor 5, several wind guide vanes 6 and a feeding cone 8, and a lower housing 7 The upper shell 3 is fixed on the upper part, and the lower shell 7 is fixed on the middle shell of the vertical mill. The lower shell 7 fixes the blanking cone 8 through the support tube 9, and the air and At the material inlet, between the feeding cone 8 and the lower casing 7, a number of wind guide blades 6 are uniformly distributed in the circumferential direction, and are used to guide the wind and the material into the swirl area generated by the rotation of the rotor. Several wind guide vanes 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com