Rinse bushing and rinsing device

A technology for flushing devices and bushings, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of large operator injury, leakage of flushing liquid, and high labor intensity, and achieve convenient storage and maintenance. Maintenance, easy installation and adjustment, saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

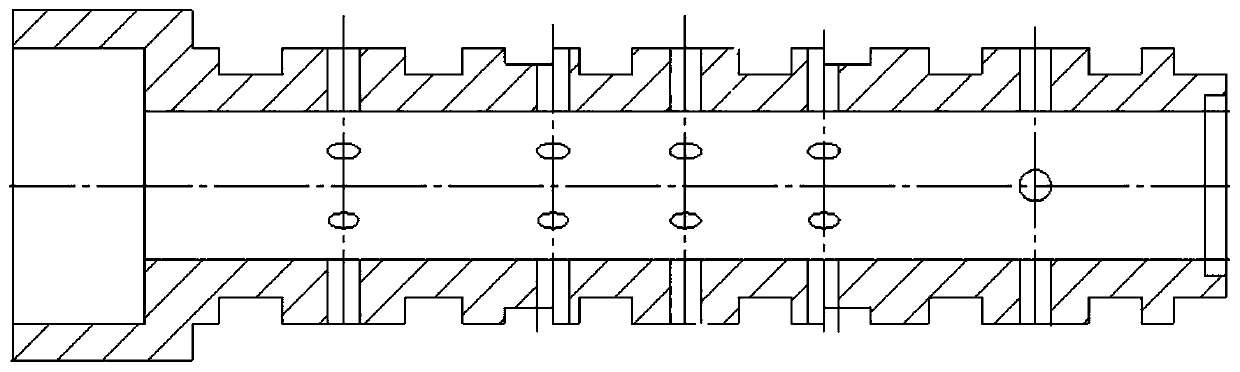

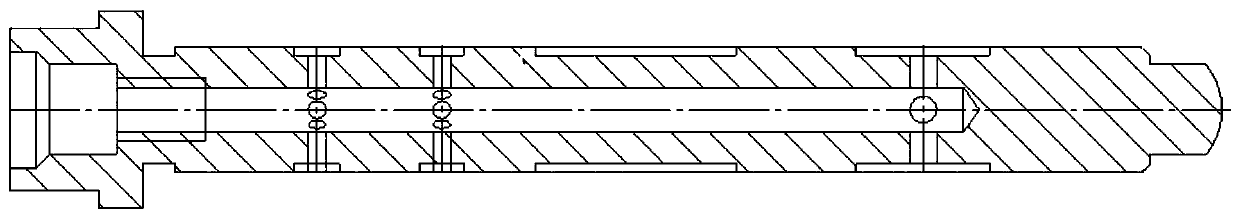

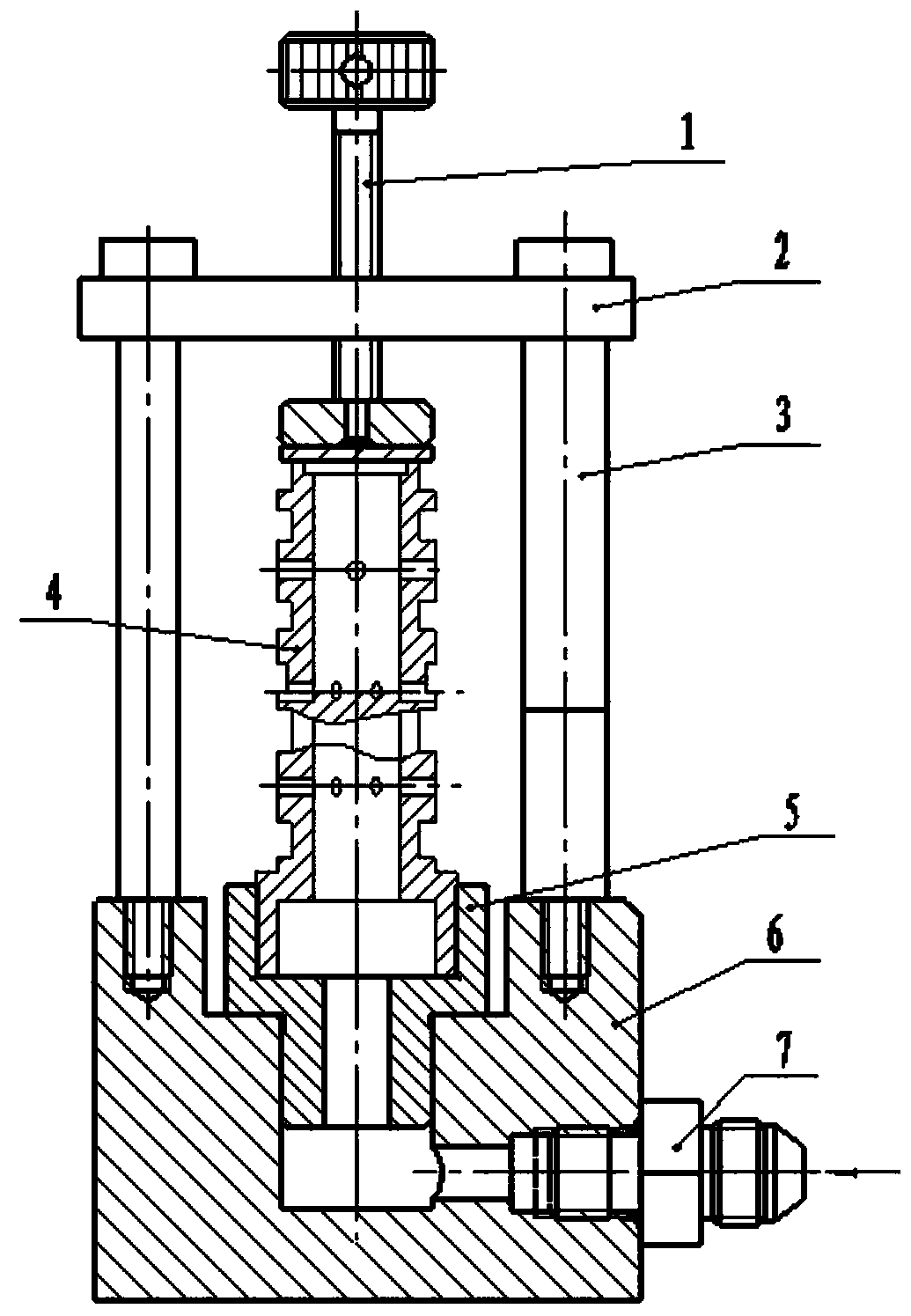

[0050] According to the above design ideas, sort out the parts that need to be washed in the accessory repair. There are large differences in the outer circle size of the ports of precision coupling parts that need to be washed, and the outer circle size ΦD of the port is mostly concentrated in the size range of Φ6.5, Φ8, Φ10, Φ12, Φ13.5, Φ17, Φ18, Φ22, Φ28 and Φ35.5 Inside. According to the above carding situation, the very close sizes are grouped into the same size range. In addition, considering the size of the contact surface when the flushing bush is installed with parts (in terms of operability), the above dimensions are divided into 2 groups to design the flushing bushing. The flushing bush installation pressing end face is designed as a new flushing bush with an angle. In addition, the clamping fixture is designed as a parallel flushing fixture clamping structure.

[0051] The redesign of the precision pair flushing device meets the needs of the entire accessory r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com