Metallographic grinding and polishing machine

A technology of grinding and polishing machines and grinding discs, which is applied in the directions of grinding frames, grinding machine parts, grinding/polishing equipment, etc. Effects of steps to avoid sandpaper replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings and embodiments. The same parts are indicated by the same reference numerals.

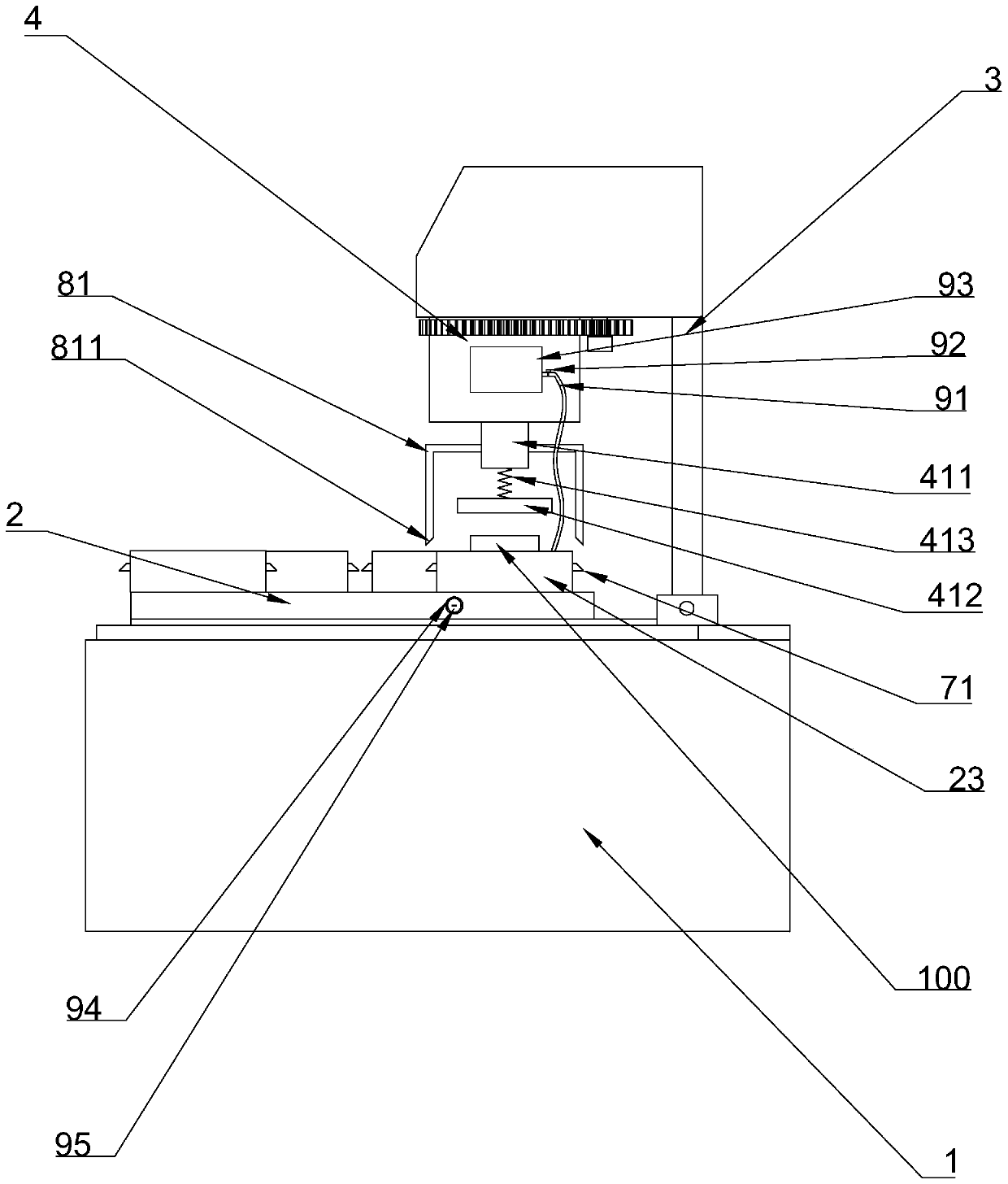

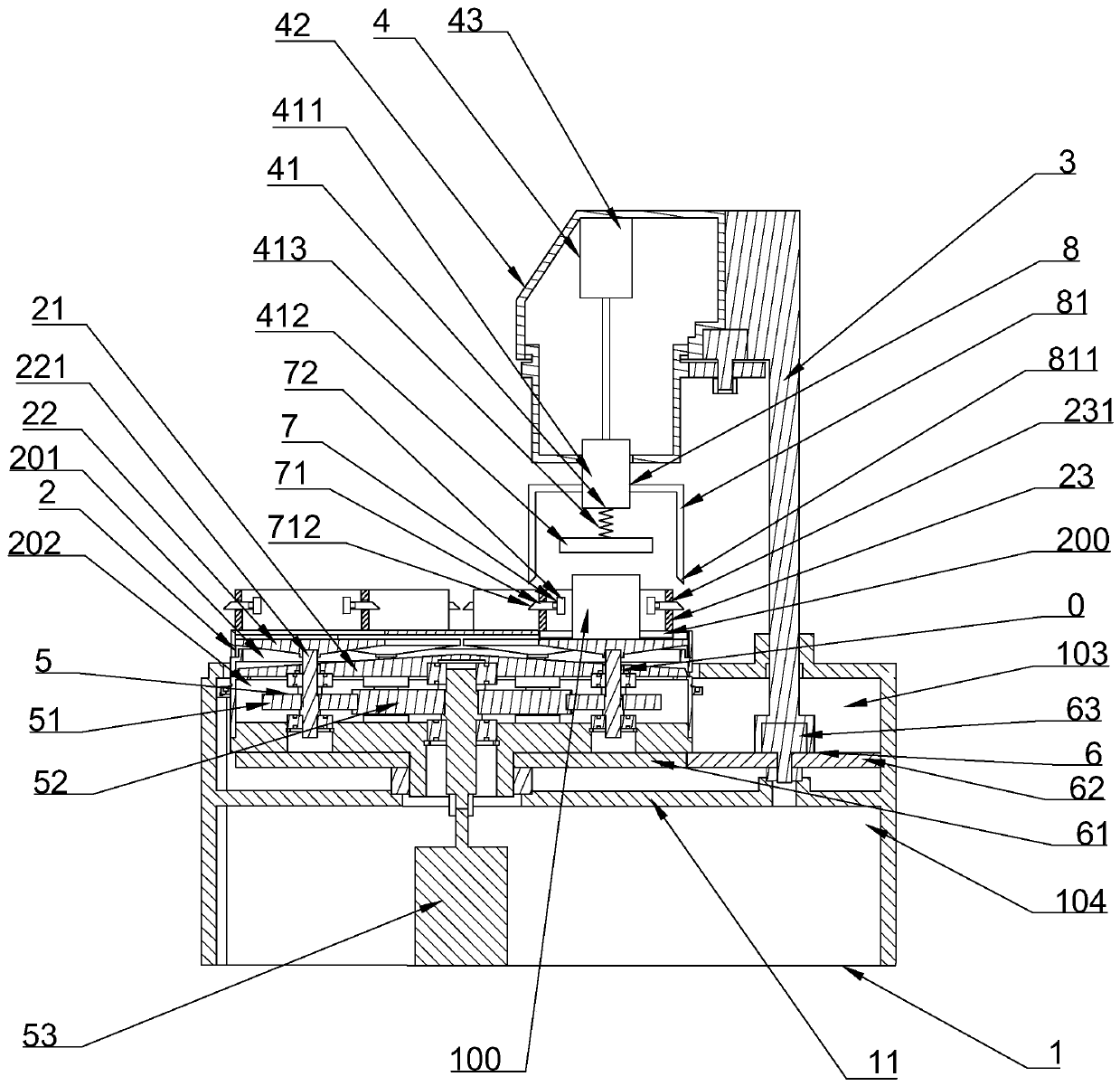

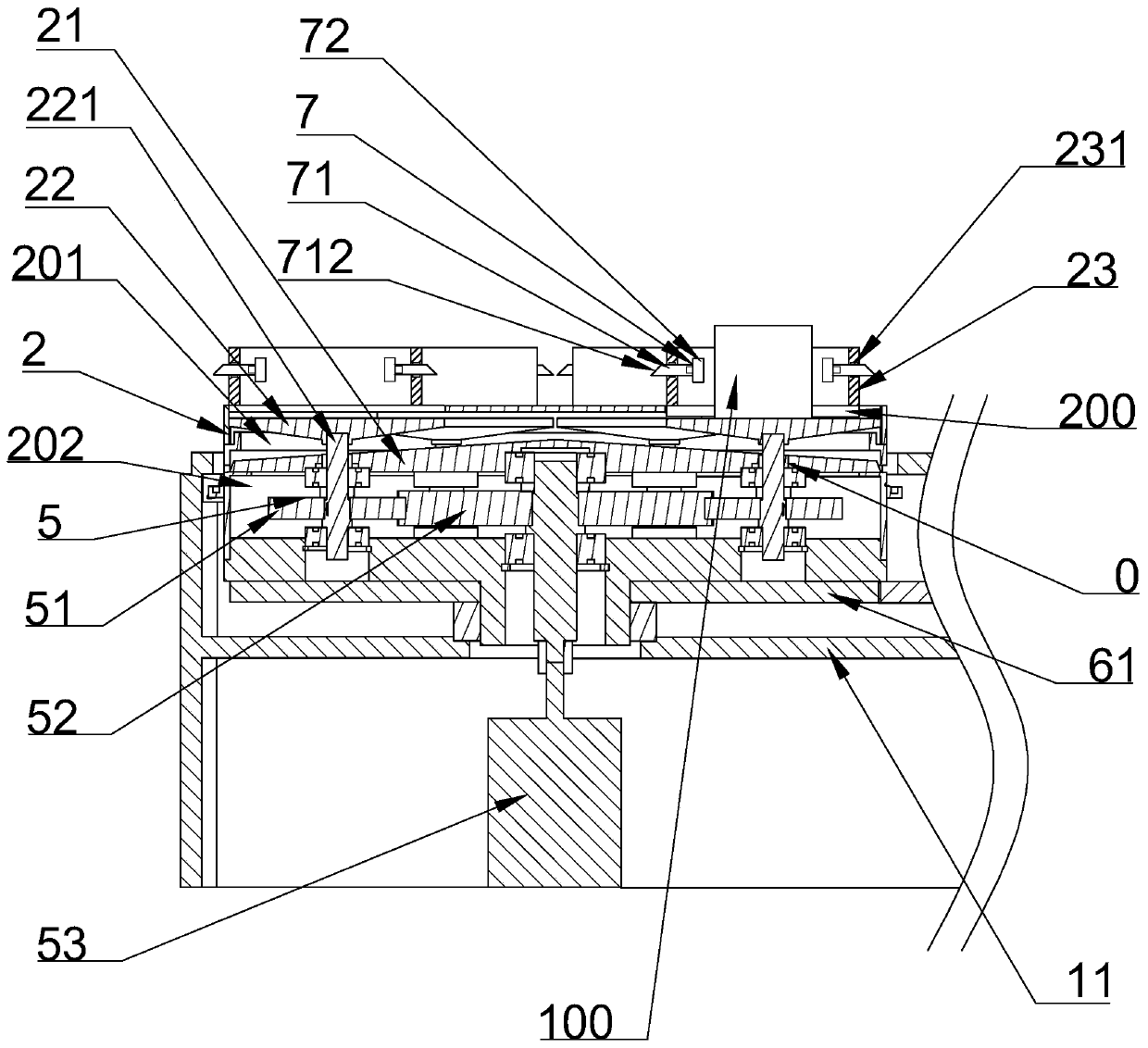

[0020] Figure 1 to Figure 5 As shown, a metallographic polishing machine of this embodiment includes a chassis 1, a carrier plate 2, a support rod 3, and a pressing device 4. The carrier plate 2 is rotatably arranged on the upper end surface of the chassis 1, so One end of the support rod 3 is connected to the upper end surface of the chassis 1, and the other end extends away from the chassis 1. The pressing device 4 is connected to the end of the support rod 3 away from the chassis 1, and the carrier plate 2 is provided with a A cavity, the upper end surface of the loading tray 2 is provided with a plurality of holding holes 200 communicating with the first cavity, and the plurality of holding holes 200 are arranged in an annular shape with the axis of the loading tray 2 as the center, A plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com