Mountain bike brake pad grinding device

A technology for making pads and mountain bikes, applied in the field of mountain bike maintenance tools, can solve the problems of unsmooth shifting, easy splashing of lubricating oil, decreased braking force, etc., to achieve the effect of saving cost and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

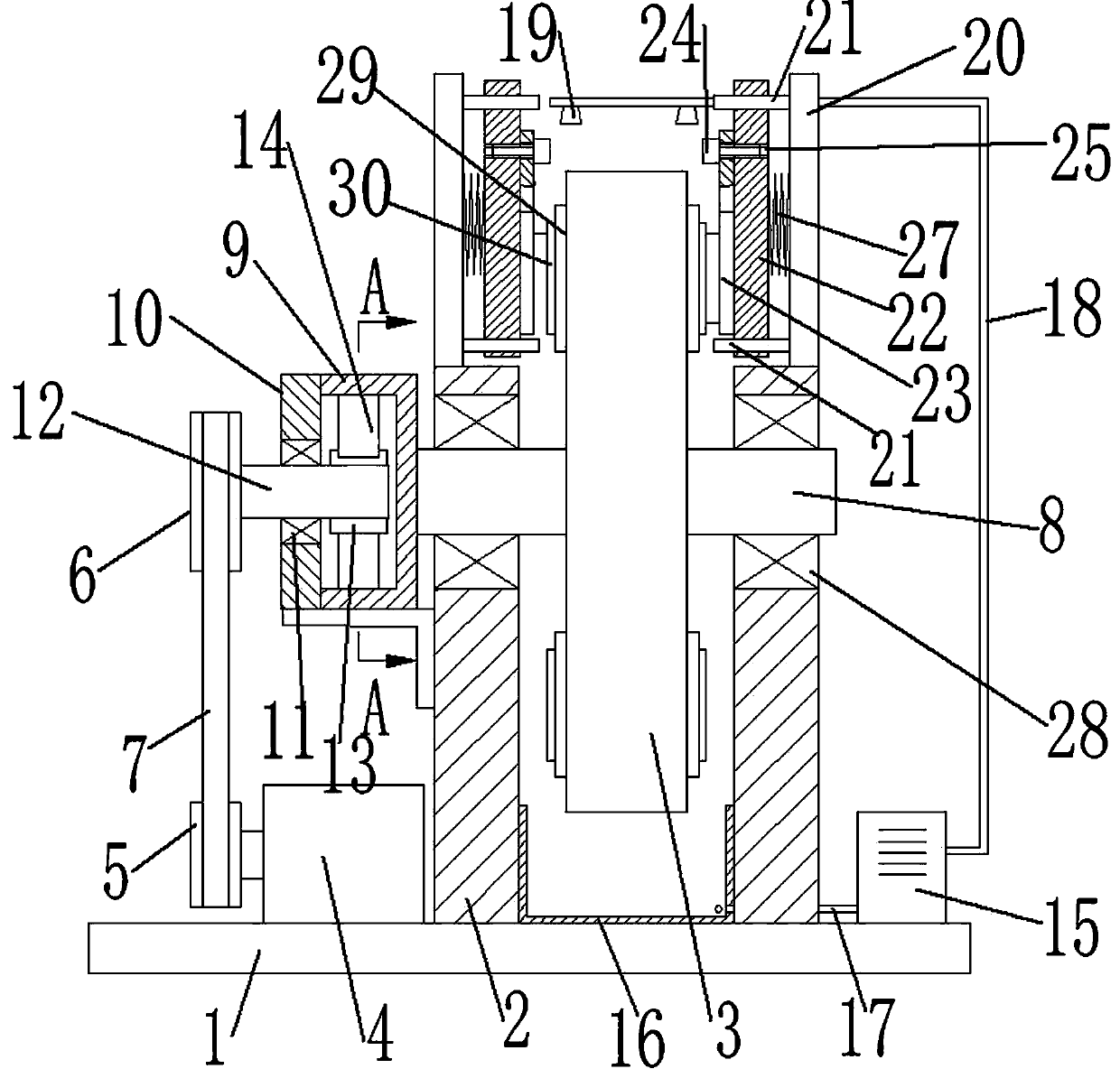

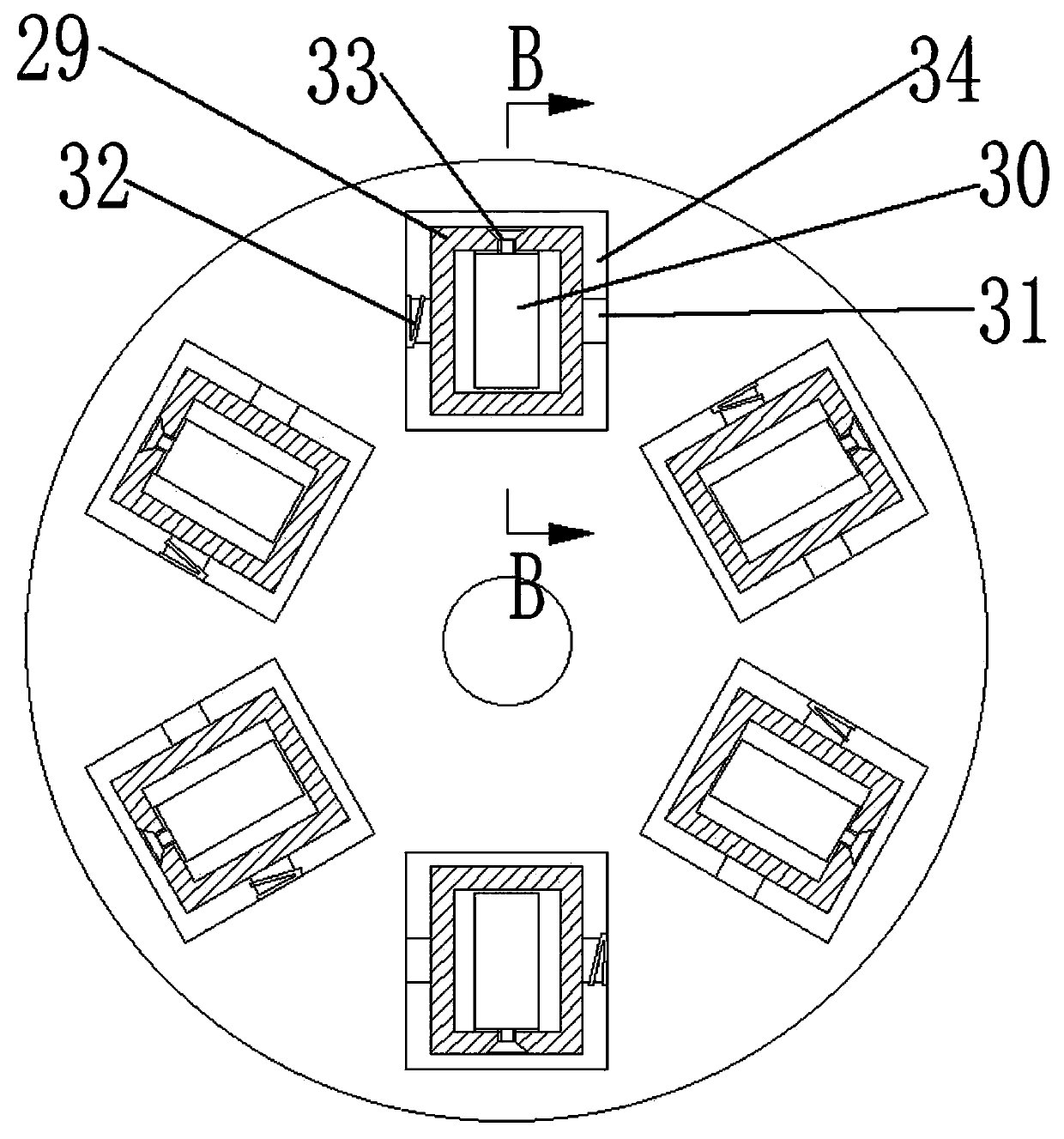

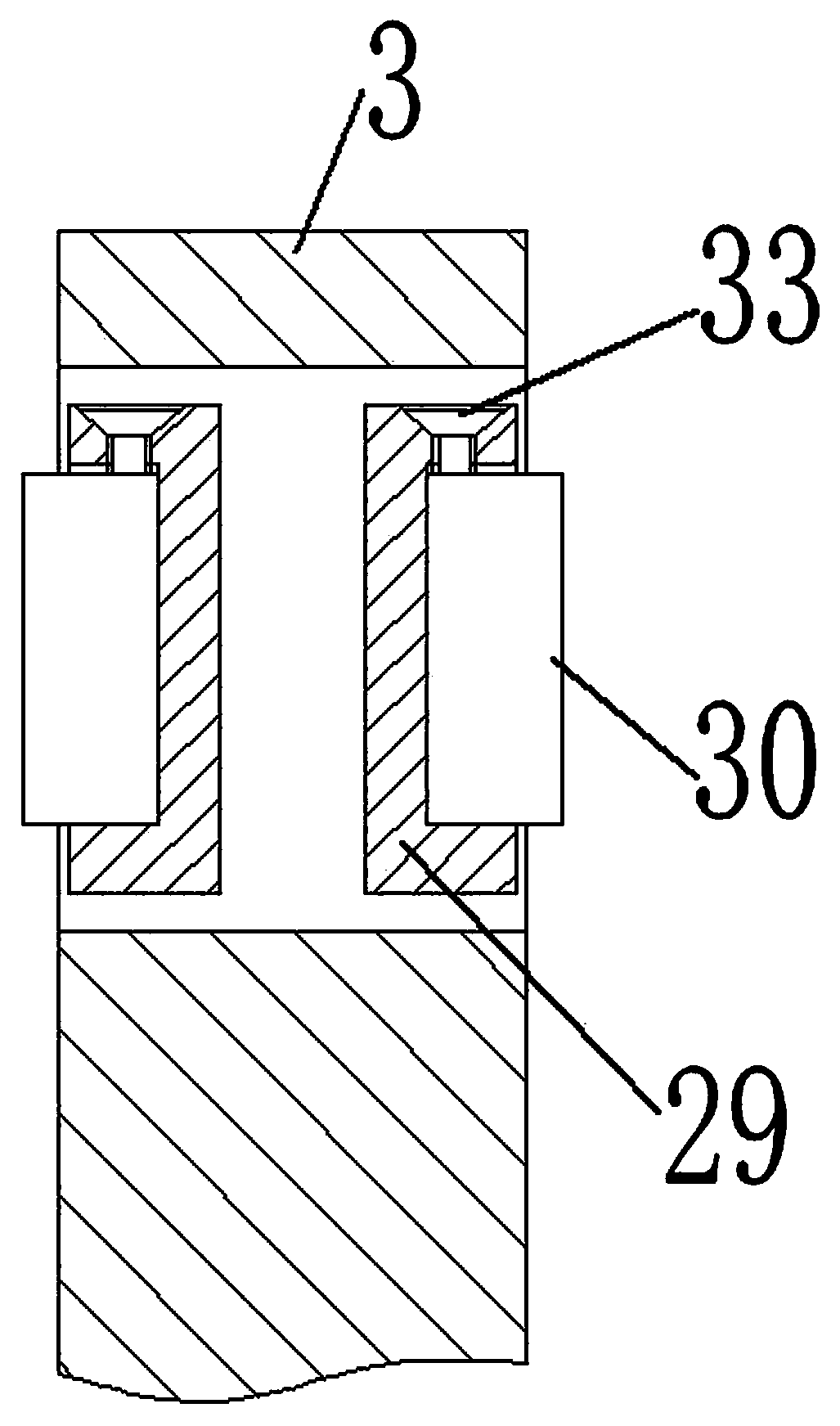

[0022] Attached below figure 1 to attach Figure 4 The present invention will be further described.

[0023] A mountain bike grinding device, comprising: a base 1, the left and right sides of the upper end of which are vertically installed with vertical plates 2; the runner 3 is located between the two vertical plates 2, and the left and right sides are coaxially arranged There is a rotating shaft 8, and the rotating shaft 8 is installed on the corresponding vertical plate 2 on the same side through the bearing II 28. The rotating wheel 3 is evenly spaced along the circumferential direction with a number of opening slots 34, and the opening slots 34 are located at the left and right ends respectively along the longitudinal direction. A sand bar 30 is provided, and the outer surface of the sand bar 30 is located at the outer end of the outer surface of the runner 3; the motor 4 is arranged on the base 1, and the vertical plate 2 is provided with a differential mechanism, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com