Pneumatic system of nail gun, pneumatic nail gun and nailing machine

A pneumatic system and nail gun technology, applied in nailing tools, manufacturing tools and other directions, can solve the problems of low nailing efficiency, increase artificial fatigue strength, and cannot use automatic nailing of plates, and achieve simple structure and easy promotion. and use, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

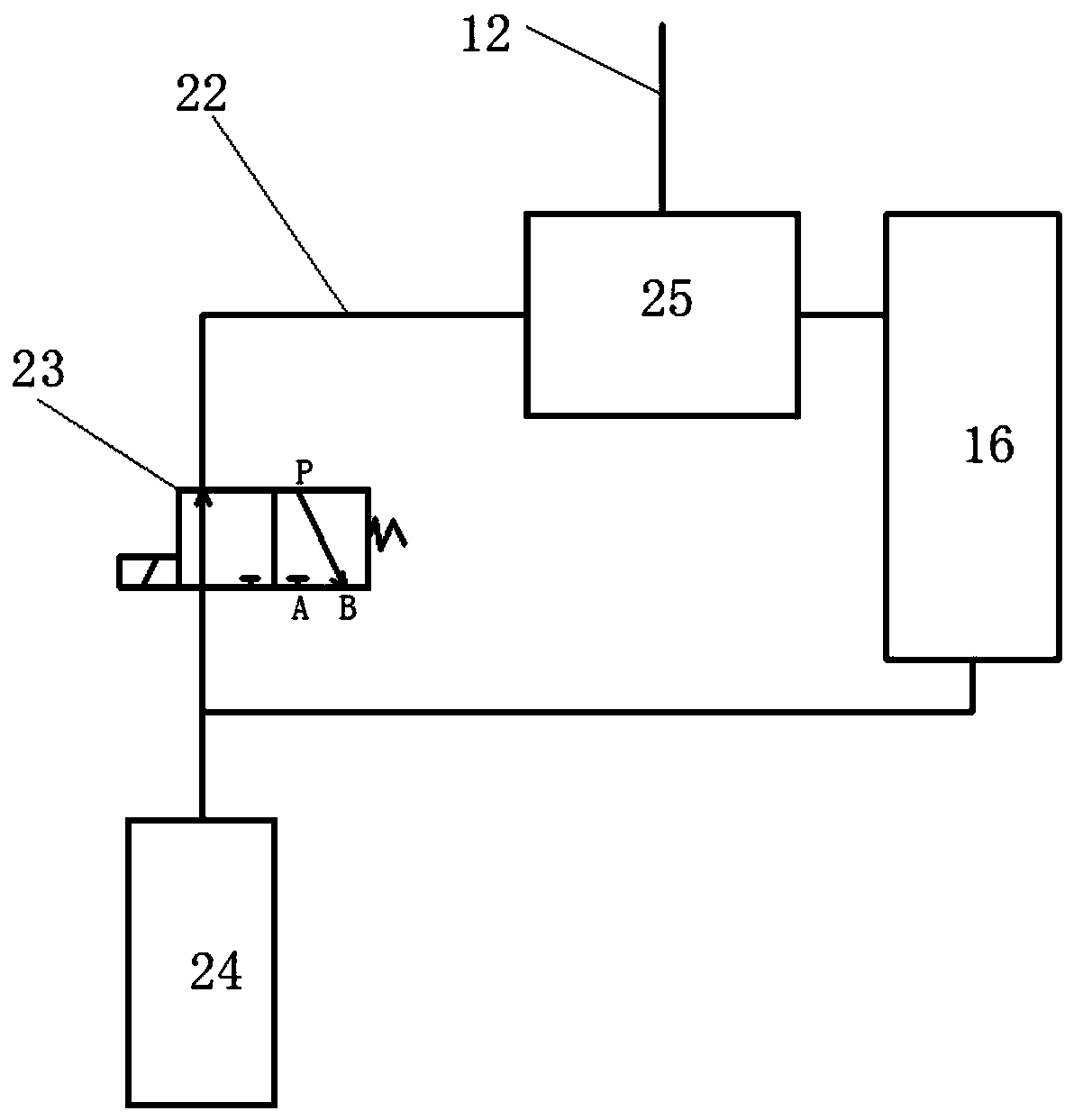

[0039] A pneumatic system of a nail gun, which includes a switching mechanism 25, an electromagnetic reversing valve 23, an air source 24 and a controller; The electromagnetic reversing valve 23 communicates with the air source 24; the air storage chamber 16 communicates with the air source 24; the electromagnetic reversing valve 23 is connected and controlled by the controller; The gas in the gas storage chamber 16 switches the communication state between the gas guide tube 12 and the gas storage chamber 16 .

[0040] The switching mechanism 25 includes a switching chamber 251, a switching piston 253 is arranged in the switching chamber 251, and a connecting seat 252 is inserted into the front end of the switching chamber 251; the connecting seat 252 is provided with a switching chamber air inlet channel 254, The front end of the switching chamber intake passage 254 is connected to the air source 24 through the switching chamber intake pipe 22, and the electromagnetic reversi...

Embodiment 2

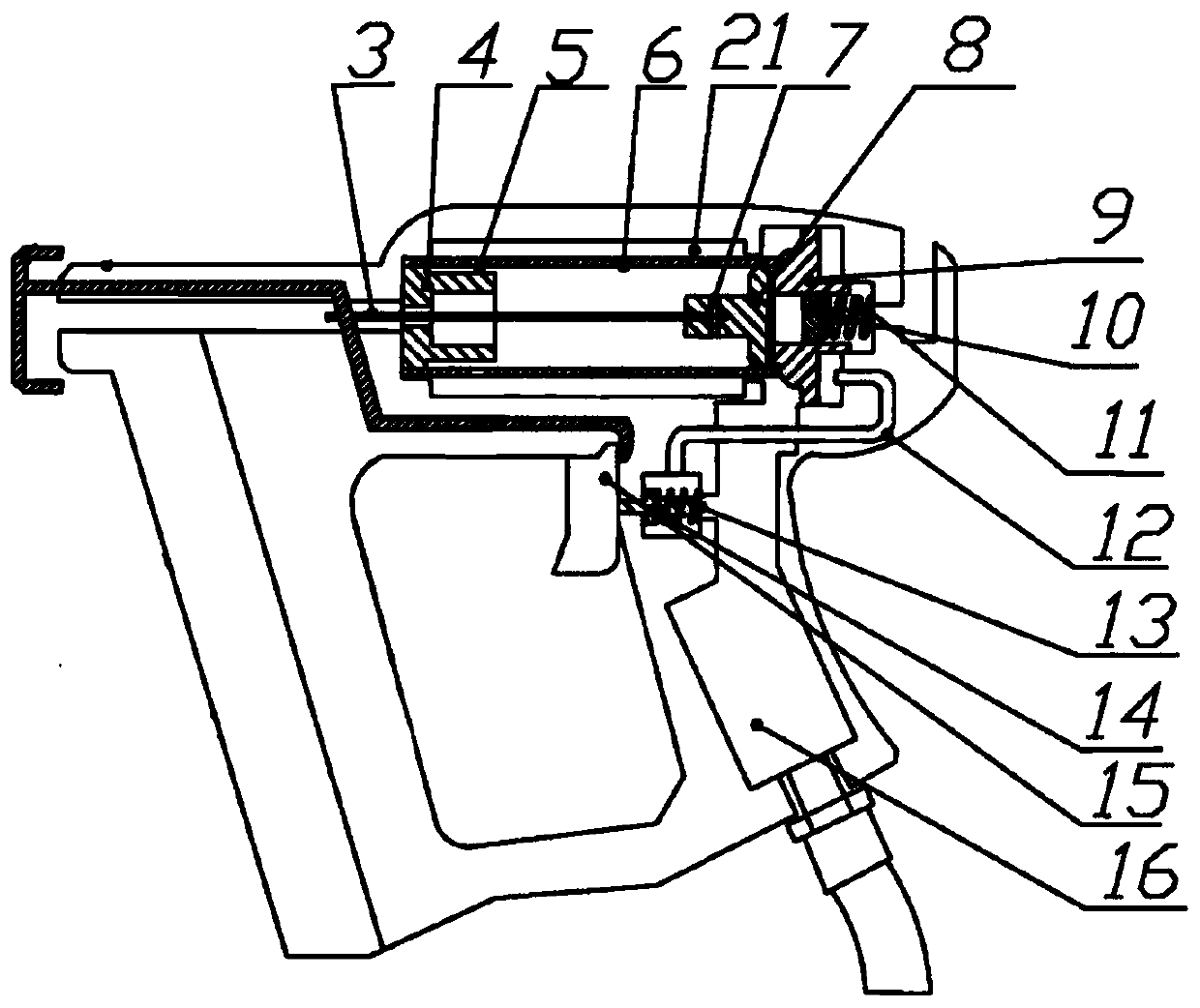

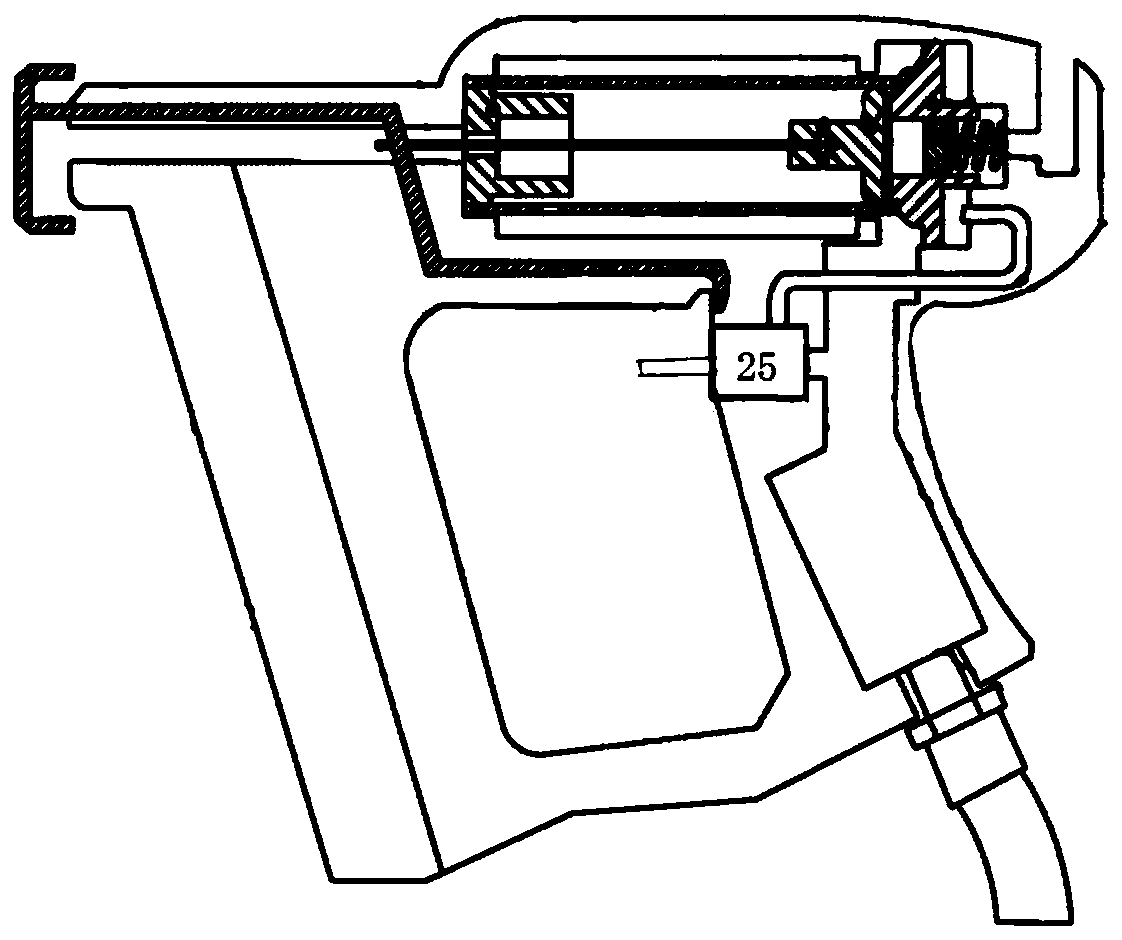

[0048] A pneumatic nail gun, which includes a gun body, a gun handle, a nail clip device, an air storage chamber 16, an air guide pipe 12, a piston 9, a firing pin rod 8, an air cylinder 6 and a firing pin 3, the gun handle is connected to the gun body, The gas storage chamber 16 is arranged inside the handle of the gun, the tail of the gas storage chamber 16 is connected to the gas source 24, the gas storage chamber 16 leads to the top of the piston 9, and a closed space is formed between the bottom of the piston 9 and the bottom of the inner wall of the gun body. It communicates with the closed space, the top of the piston 9 is connected to the bottom of the gas cylinder 6, the top of the gas cylinder 6 is equipped with a gas cylinder plug 4, the outer wall of the gas cylinder 6 is provided with a gas cylinder hole 5, the center of the gas cylinder plug 4 is provided with a channel, and the striker rod 8 is installed inside the gas cylinder 6, The bottom of the firing pin rod...

Embodiment 3

[0057] An automatic nailing machine, which includes the pneumatic nail gun in Embodiment 2, the pneumatic nail gun is arranged on the body, and the body is used to drive the pneumatic nail gun forward, backward, left, right, up, Move down.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap